Method and device for simultaneously catalytic-generating hydrogen in waste battery recycling process

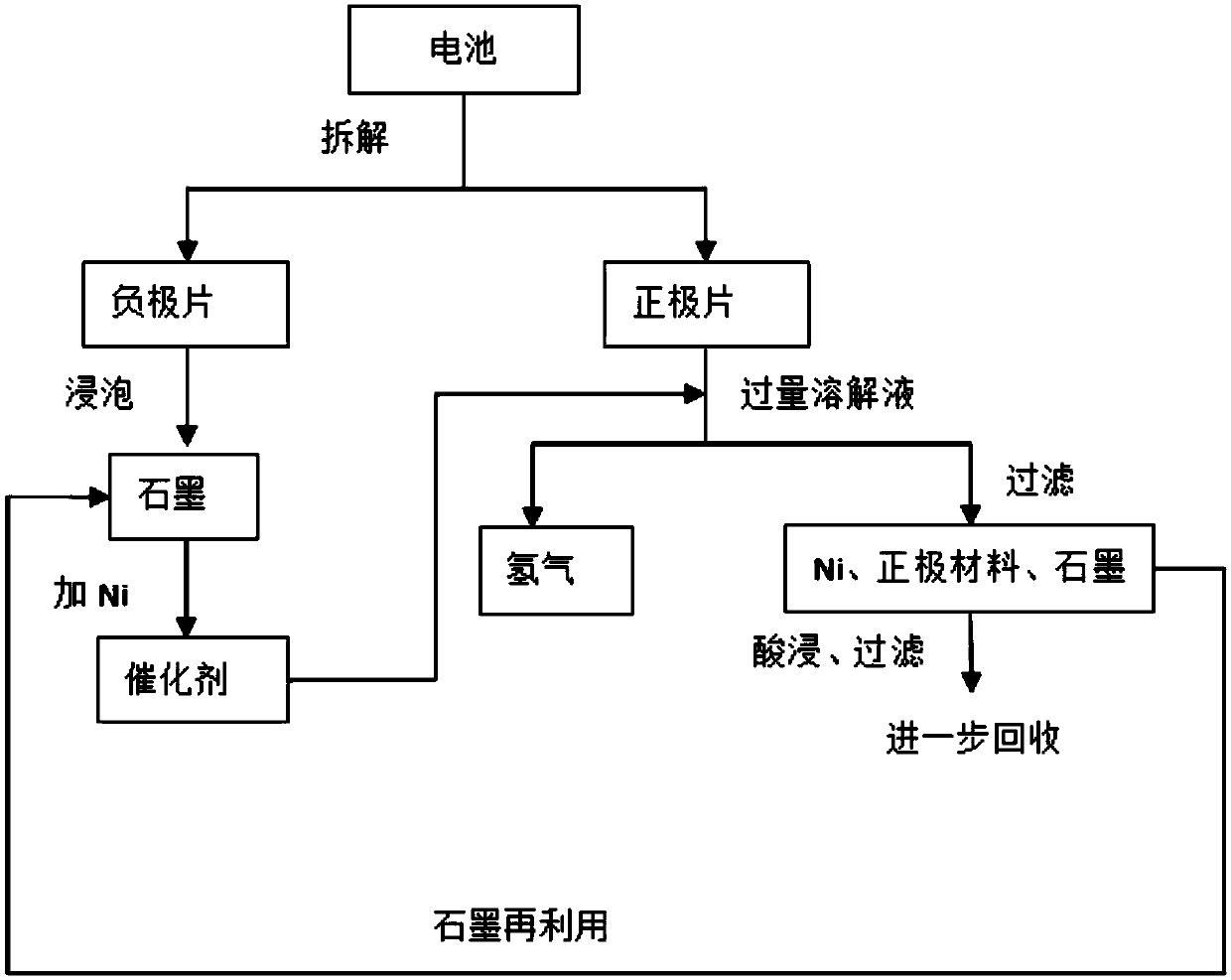

A technology for used batteries and catalysts, which is used in battery recycling, waste collector recycling, chemical instruments and methods, etc., can solve the problems of safety, unreported, and low content in the battery recycling area, and achieves wide applicability and danger. The effect of low sexuality and moderate reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

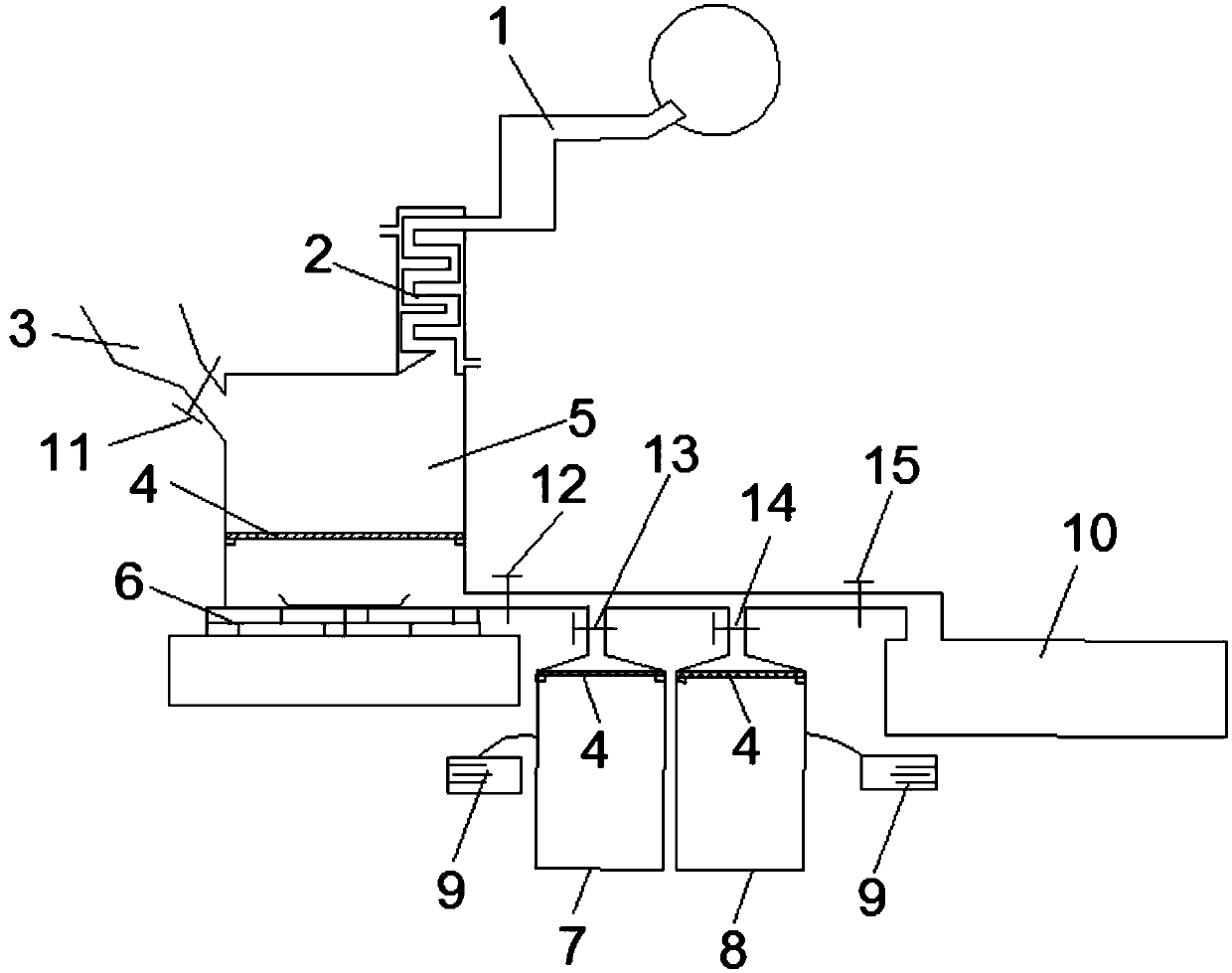

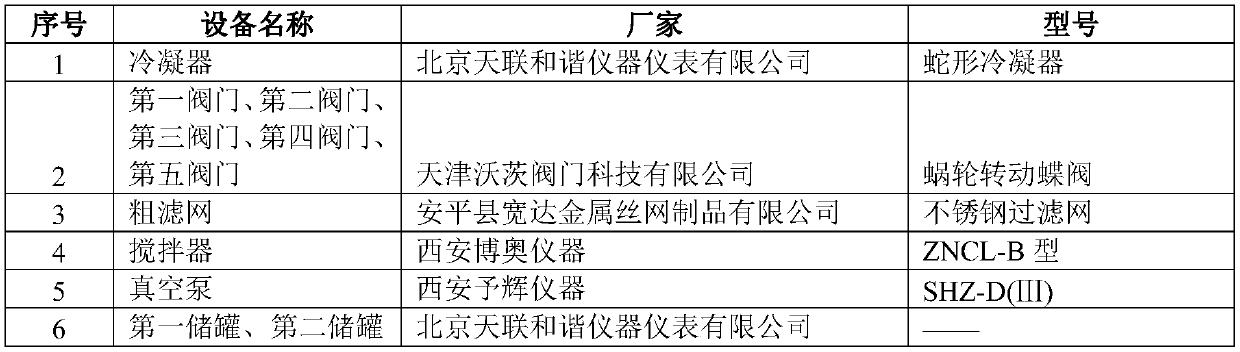

[0039] Select waste and used lithium iron phosphate battery cells from Tianjin Lishen Battery Co., Ltd. for manual disassembly, separate the positive electrode sheet, negative electrode sheet, etc., take 5g of negative electrode material fragments, open the first valve, and put them into the reactor through the feed port. Add 50ml of 60°C hot water to the coarse filter, stir until the black substance on the surface of the negative electrode separates, open the second valve, and the black slurry flows into the first storage tank. Remove the coarse strainer and collect the copper foil on top. Take 0.15g Ni(NO 3 )2 Put into 20ml deionized water, stir until dissolved to get Ni(NO 3 ) 2 solution, open the first storage tank, add the solution to the first storage tank, impregnate overnight under stirring conditions, then stir and evaporate the slurry to dryness, dry the evaporated matter at 80°C for 8h, and calcinate at 500°C under nitrogen atmosphere 5h, a Ni / C catalyst was obta...

Embodiment 2

[0042] Select CATL's waste ternary lithium-ion battery cells, manually disassemble them, separate the positive electrode sheet, negative electrode sheet, etc., take 5g of negative electrode material fragments, open the first valve, and put them into the coarse filter screen in the reactor through the feed port. Add 50ml of 70°C hot water, stir until the black substance on the surface of the negative electrode separates, open the second valve, and the black slurry flows into the first storage tank. Remove the coarse strainer and collect the copper foil on top. Take 0.15g Ni(NO 3 ) 2 Put into 20ml deionized water, stir until dissolved to get Ni(NO 3 ) 2 Solution, open the first storage tank, add the solution into the first storage tank, impregnate overnight under the condition of stirring, then stir and evaporate the slurry to dryness, dry the evaporated product at 90°C for 8h, and calcinate at 500°C under nitrogen atmosphere 5h, a Ni / C catalyst was obtained.

[0043] Open ...

Embodiment 3

[0045] Select the waste ternary lithium-ion battery unit of AVIC Lithium Battery, manually disassemble, separate the positive electrode sheet, negative electrode sheet, etc., take 5g of negative electrode material fragments, open the first valve, and put them into the coarse filter in the reactor through the feed port , add 50ml of 80°C hot water, stir until the black substance on the surface of the negative electrode separates, open the second valve, and the black slurry flows into the first storage tank. Remove the coarse strainer and collect the copper foil on top. Take 0.25g Ni(NO 3 ) 2 Put into 20ml deionized water, stir until dissolved to get Ni(NO 3 ) 2 solution, open the first storage tank, add the solution into the first storage tank, impregnate overnight under stirring conditions, then stir and evaporate the slurry to dryness, dry the evaporated matter at 100°C for 8h, and calcinate at 500°C under nitrogen atmosphere 5h, a Ni / C catalyst was obtained.

[0046] Op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com