Hydration synthesis method of magnesium hydroxide slurry material with controllable dissolution rate

A magnesium hydroxide and hydration technology, applied in the direction of magnesium hydroxide, etc., can solve the problems not involved in the regulation of the dissolution rate of magnesium hydroxide slurry, and achieve the effect of reducing agglomeration and increasing the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

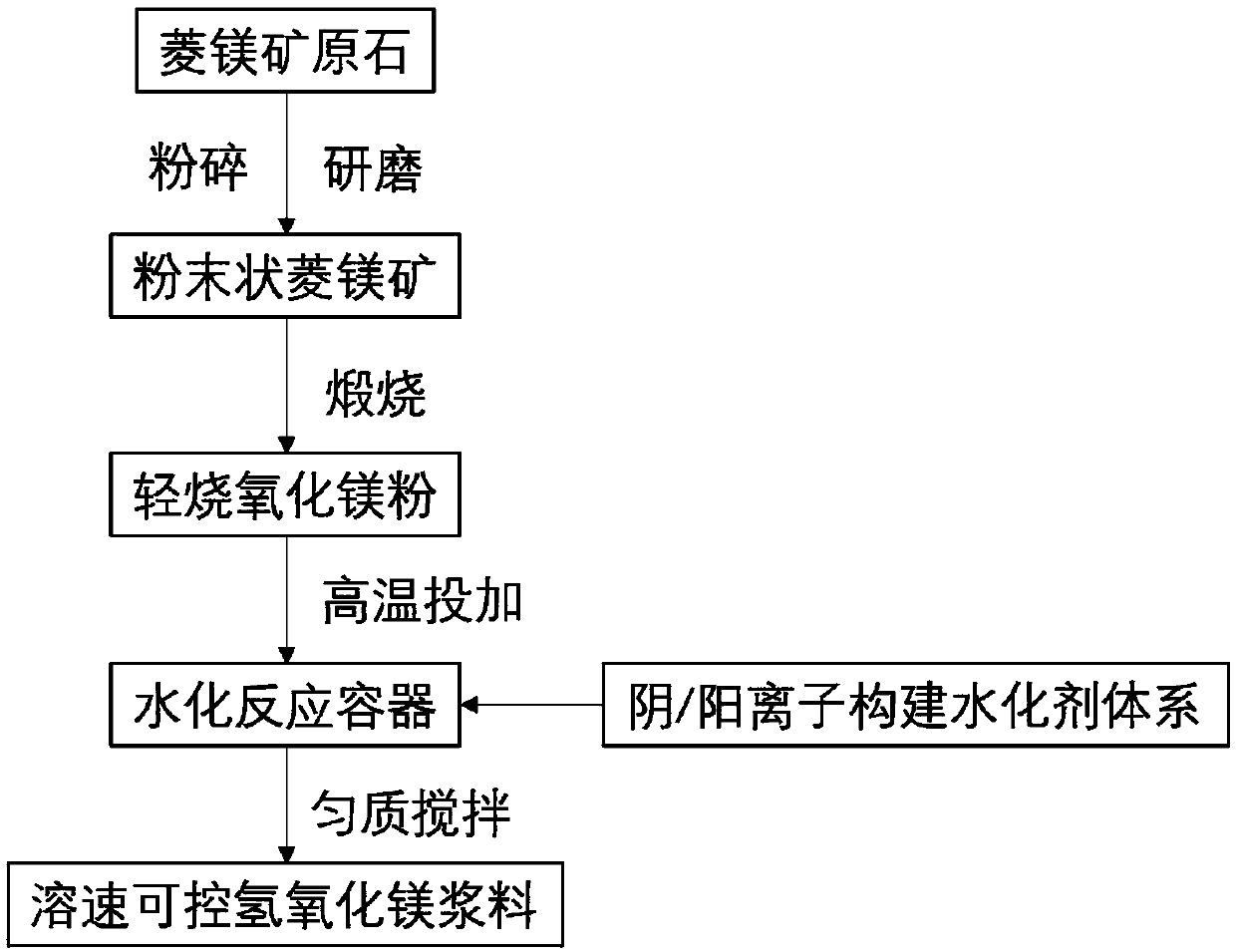

[0026] A kind of magnesium hydroxide slurry hydration synthetic method with controllable dissolution rate, described method comprises the steps:

[0027] Crush 4000g of magnesite raw stone to 1250 mesh, and calcined at 650°C for 3 hours to obtain light-calcined magnesium oxide powder;

[0028] Add 20g of lightly calcined magnesium oxide powder to 200mL of hydration agent solution while maintaining the calcining temperature, and stir homogeneously to obtain magnesium hydroxide slurry;

[0029] The hydrating agent solution is sodium acetate with a concentration of 1%;

[0030] The homogeneous stirring speed is 1300rpm;

[0031] The time of the hydration reaction is 0.5h;

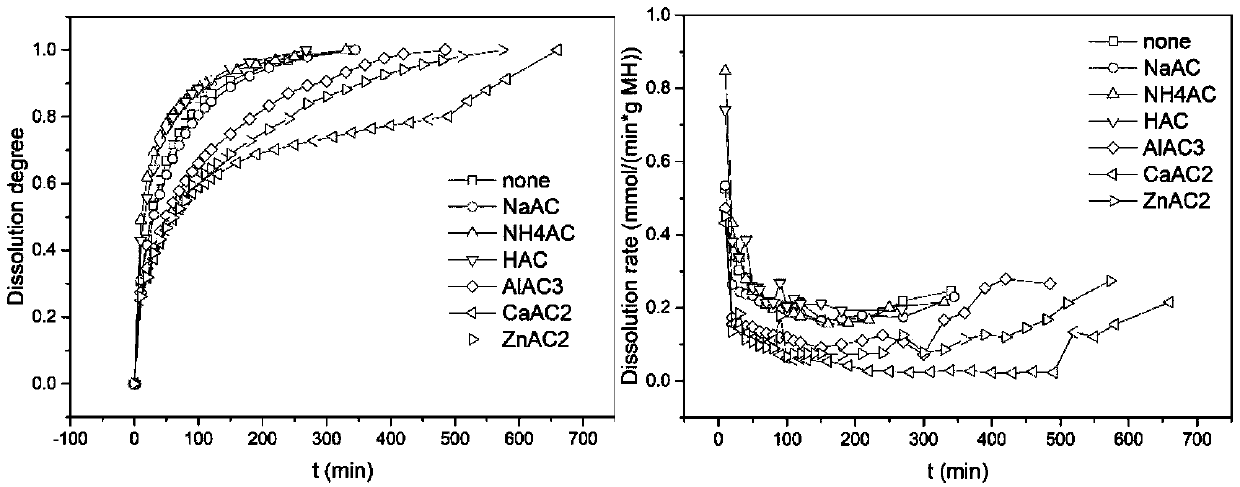

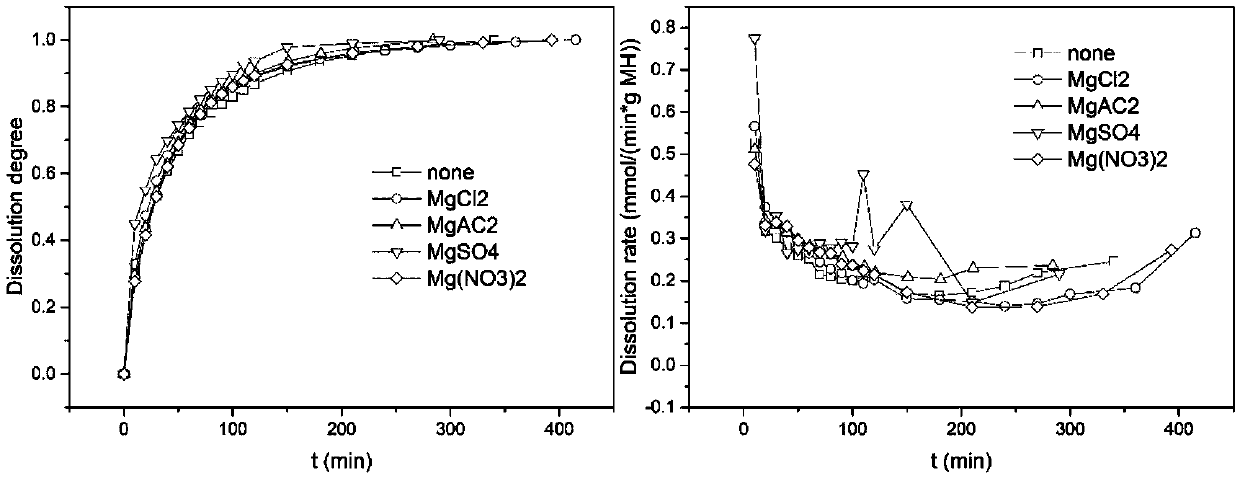

[0032] The dissolution rate of magnesium hydroxide slurry was measured by constant pH titration method, and no hydration agent was added to the control group.

Embodiment 2

[0034] A magnesium hydroxide slurry hydration synthesis method with controllable dissolution rate, the difference from Example 1 is that the hydration agent solution is ammonium acetate.

Embodiment 3

[0036] A magnesium hydroxide slurry hydration synthesis method with controllable dissolution rate, the difference from Example 1 is that the hydration agent solution is acetic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com