Method of removing impurities in finished iron black produced with wastes and application of method

A technology of iron black and products, which is applied in the field of environmental protection waste recycling, can solve the problems of increasing operating costs and large consumption of cleaning water, so as to reduce production costs, solve the problem of salty wastewater, and achieve good economic and environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for removing impurities from waste production iron black removal products:

[0038] (1) First, set up a three-stage offline washing high-pressure plate and frame filter press and a first-stage online washing high-pressure plate and frame filter press; the first-level offline cleaning system: an online washing high-pressure plate and frame filter press and a washing tank; cleaning The cleaning water of the system comes from the desalted water or tap water of the evaporative crystallization system in the subsequent process, and the cleaning water directly enters the cleaning water inlet of the online washing high-pressure plate and frame filter press for online cleaning of iron black products. The rinsing project after the production of iron black products by using pickling waste hydrochloric acid and pickling sludge in a steel company was selected.

[0039] (2) Set up a beating tank and a buffer tank in each level of offline washing to facilitate the thorough mi...

Embodiment 2

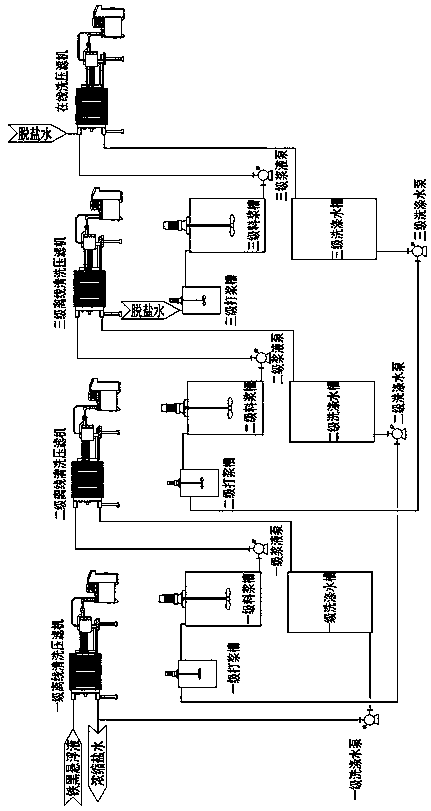

[0048] As shown in accompanying drawing, the method that the present invention utilizes waste production iron black to remove product removal of impurities is:

[0049] First, the iron-black mixed liquor passes through the first-level off-line cleaning system, the second-level off-line cleaning system, the third-level off-line cleaning system and the on-line cleaning system.

[0050] Each level of off-line cleaning system includes off-line cleaning filter press, slurry tank, slurry tank, washing water tank and auxiliary lift pump. The off-line cleaning filter press dehydrates the iron black product in the mixture to form a filter cake with a moisture content of 40%.

[0051] The beating tank fully mixes the filter cake produced by the filter press with the filtered filtrate discharged from the upper stage to dilute the concentration of inorganic salts in the filter cake.

[0052] The slurry tank acts as a buffer tank, that is, to store the iron-black mixed liquid formed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com