Mobile Pickling Waste Liquid Treatment System

A technology of pickling waste liquid and treatment system, which is applied in the direction of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of not being open to the public and not exceeding the annual index Disposal, non-acceptance and other issues to achieve the effect of preventing the discharge of unqualified filtrate, saving tap water resources and reducing environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

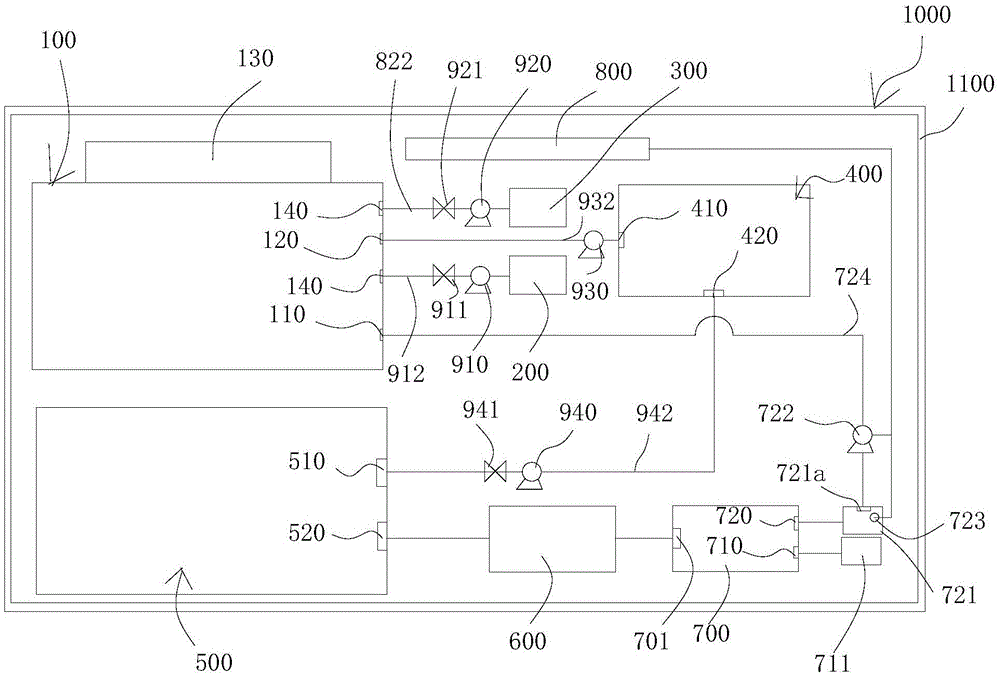

[0036] see figure 1 The shown mobile pickling waste treatment system includes a mobile box 1000, which in this embodiment is a container, and of course it can be other mobile boxes that are easily conceived by those skilled in the art. In order to reduce the working noise of the present invention, a noise reduction layer 1100 is provided on the inner wall of the moving box 1000 . In order to facilitate the inspection and work of the present invention at night, a lighting device is also arranged in the mobile box 1000 .

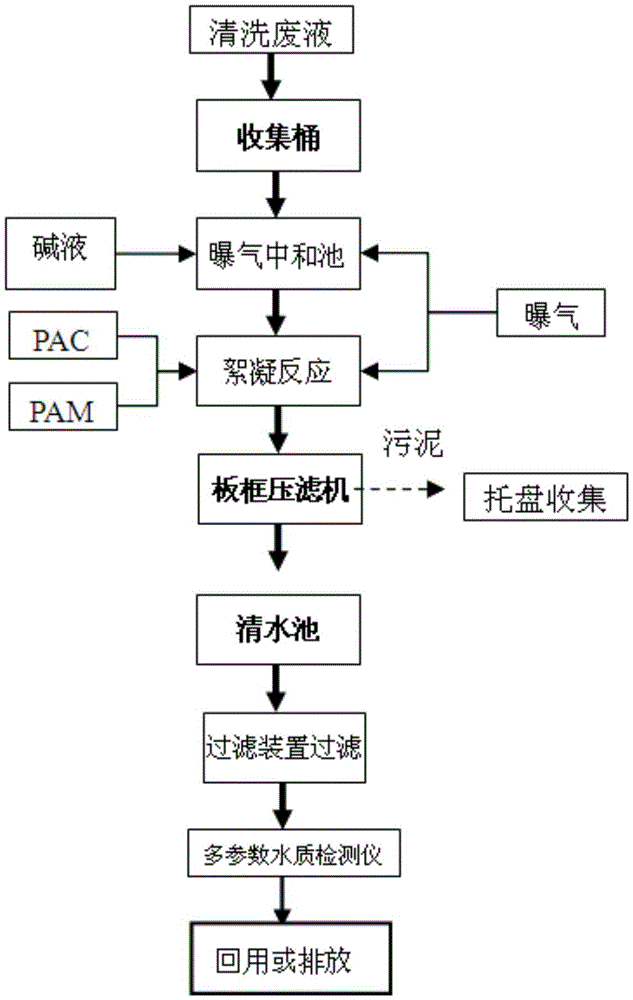

[0037] In the mobile box 1000, an aeration neutralization tank 100, an aeration device (not shown in the figure), an alkali solution addition device 200, a flocculant addition device 300, a filter press 400, a clear liquid tank 500, and a filter device are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com