A kind of quaternized lignin dispersed graphene/carbon nanotube based composite anticorrosion coating and its preparation method and application

A technology of carbon nanotubes and dispersed graphite, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of water-based materials that are difficult to disperse and limit applications, so as to reduce the corrosion path, delay the corrosion rate, and be easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This example provides a method for preparing a quaternized lignin-dispersed graphene / carbon nanotube-based composite anticorrosion coating.

[0060] (1) Purify and dry alkali lignin before use, add sodium hydroxide solid to 45ml deionized water to obtain a 20wt.% sodium hydroxide solution, then add alkali lignin to obtain sodium hydroxide with a concentration of 0.16g / mL The dissolved alkali lignin solution was ultrasonically dispersed for 15 minutes. According to mass ratio alkali lignin: the proportioning of 3-chloro-2-hydroxypropyltrimethylammonium chloride solution=1:0.83, 3-chloro-2-hydroxypropyltrimethylammonium chloride solution (60 wt.%) was added dropwise to the above-mentioned lignin alkali solution, stirred and reacted at 85°C for 4h, after the reaction was completed, cooled to room temperature to obtain a reaction solution, which was purified by dialysis with a 1000 molecular weight dialysis bag, and the dialysis after dialysis The reaction solution was dri...

Embodiment 2

[0065] This example provides the application of the quaternized lignin-dispersed graphene / carbon nanotube-based composite anticorrosion coating prepared in Example 1 and its comparative example.

[0066] (1) Preparation of waterborne epoxy coating (WEP):

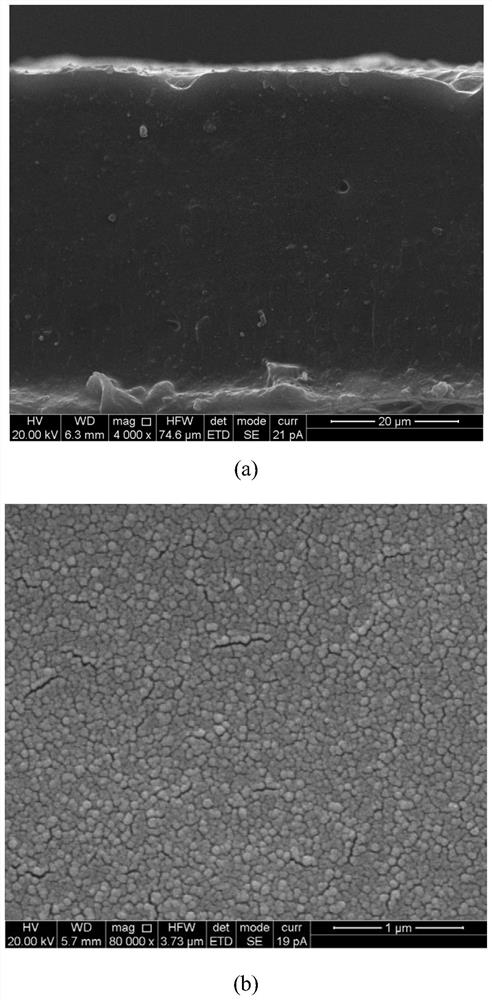

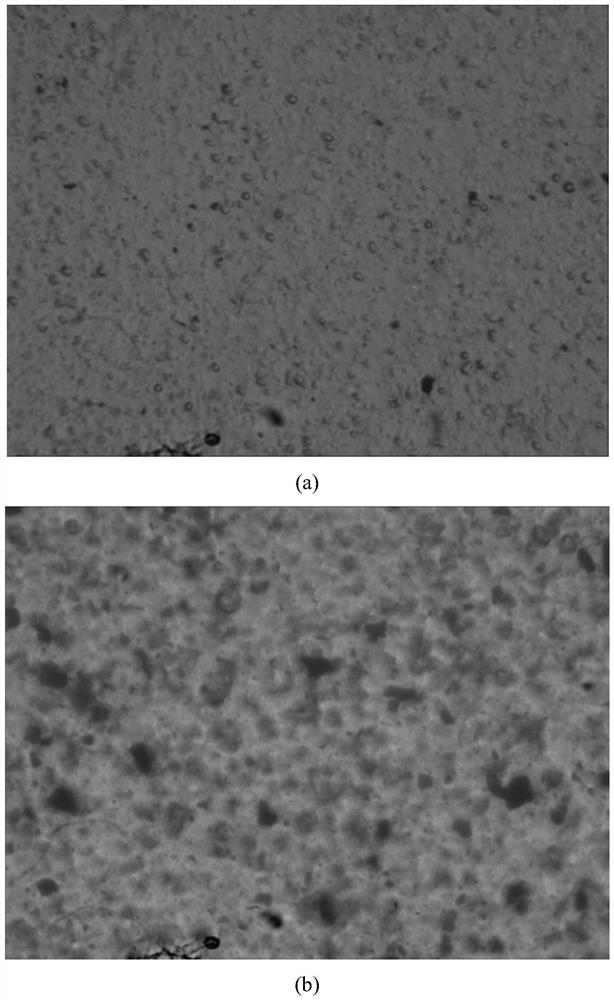

[0067] Mix 4.25 parts by mass of water-based curing agent DY-175, 1 part by mass of deionized water and 5 parts by mass of water-based epoxy resin DY-128-50 at room temperature with mechanical stirring, and ultrasonically disperse in an ultrasonic cleaner at 20KHz For 10 minutes, under the condition of ice bath in a vacuum oven, vacuum out the air bubbles; after the air bubbles are completely removed, use a spin coater to coat a 25 μm thick coating on Q235 carbon steel. Curing at room temperature for 5 hours to obtain a waterborne epoxy coating.

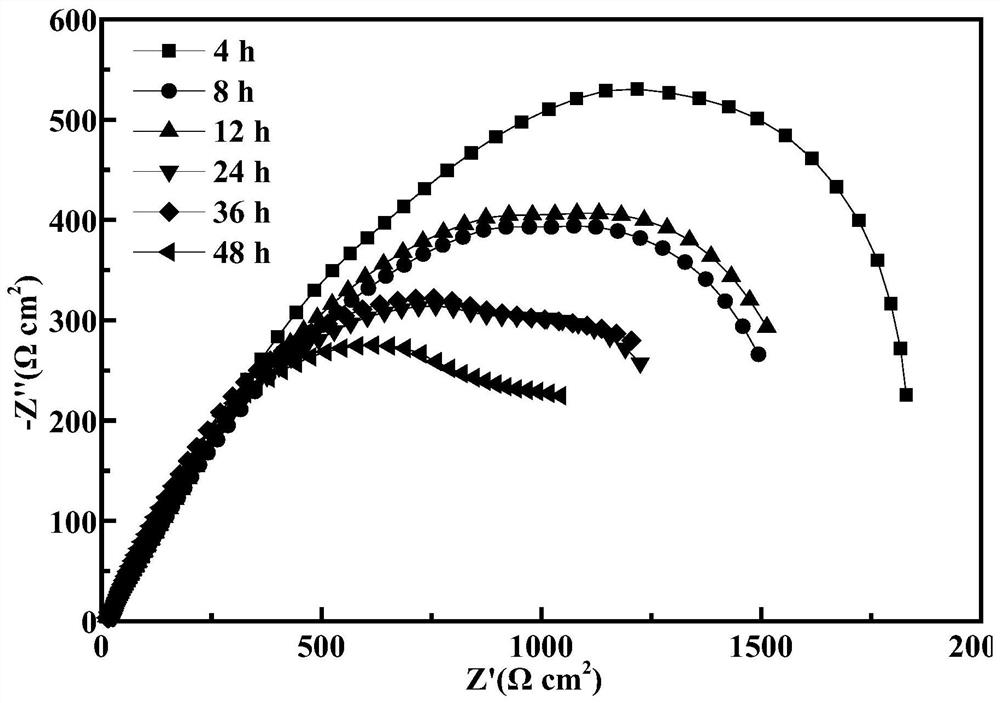

[0068] (2) Preparation of graphene-based composite anticorrosion coatings dispersed in quaternized lignin:

[0069] Dissolve the quaternized lignin in water to obtain a quaterniz...

Embodiment 3

[0076] This example provides a method for preparing a quaternized lignin-dispersed graphene / carbon nanotube-based composite anticorrosion coating.

[0077] (1) Purify and dry the high boiling alcohol lignin before use, add solid sodium hydroxide to 45ml deionized water to obtain a 20wt.% sodium hydroxide solution, then add high boiling alcohol lignin to obtain a concentration of 0.16g / mL High-boiling alcohol lignin solution dissolved in sodium hydroxide, ultrasonically dispersed for 15 minutes. According to the ratio of mass ratio high boiling alcohol lignin: 3-chloro-2-hydroxypropyl trimethyl ammonium chloride solution=1:0.83, the 3-chloro-2-hydroxypropyl trimethyl ammonium chloride solution (60wt.%) was added dropwise in the above-mentioned lignin alkali solution, stirred and reacted at 85°C for 4h, after the reaction was completed, cooled to room temperature to obtain a reaction solution, the reaction solution was purified by dialysis with a 800 molecular weight dialysis ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com