Preparation method of asparagus agar-oligosaccharide resisting melanin synthesis, and product and application thereof

A technology of agar oligosaccharides and melanin, which is applied in the field of preparation of non-agar oligosaccharides from Asparagus anti-melanin, which can solve the problems of process preparation and medicinal activity differences, non-agar polysaccharide yield and immune activity decline, etc. , to achieve the effects of increasing economic added value, increasing the strength of agar gel, and increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

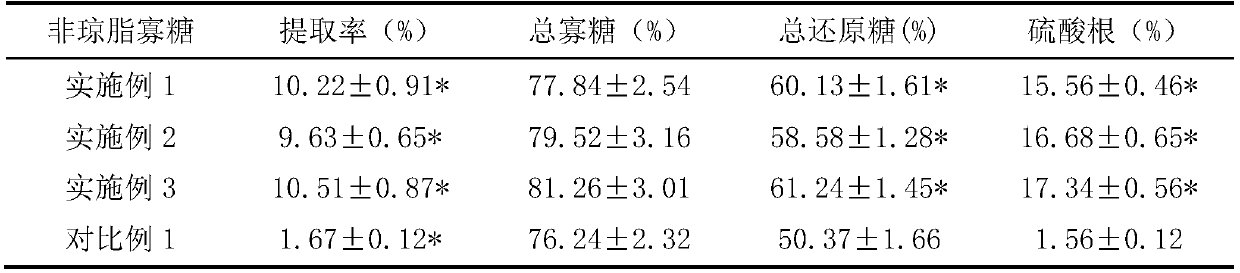

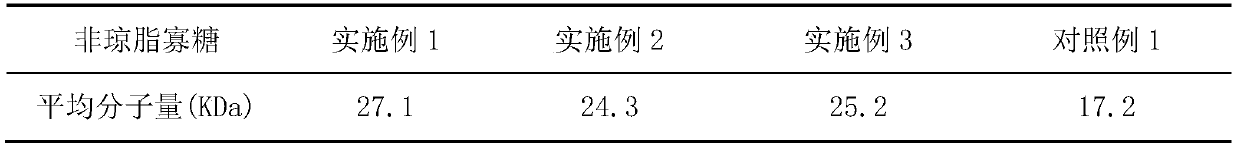

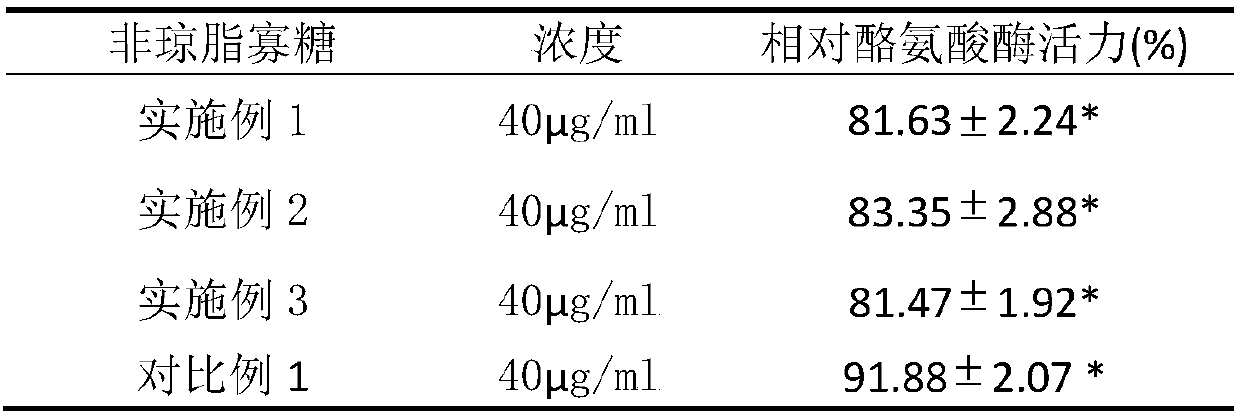

Examples

Embodiment 1

[0026] A kind of preparation method of asparagus non-agar oligosaccharide is as follows:

[0027] (1) Asparagus is washed, desalted, dried, crushed through a 4-mesh sieve, added 3% hydrochloric acid solution with a volume ratio 3 times that of asparagus, bathed in 70°C water for 90 minutes, filtered while hot, discarding the filtrate, and drying the algae Dry;

[0028] (2) Add 9 times the volume of distilled water to the obtained algal body, extract twice by ultrasonic method, the ultrasonic power is 180-420W, the extraction temperature is 45-75°C, and the extraction time is 60-120 minutes; filter and combine the filtrate;

[0029] (3) The filtrate was concentrated to a relative density of 1.75 by vacuum distillation, refrigerated at 4°C for 6h, centrifuged at 1500rpm / min at 4°C for 10min, and the colloid was separated;

[0030] (4) The colloid was frozen in a freezer at -80°C for 5 hours, thawed at 4°C for 6 hours, centrifuged at 1500rpm / min, 4°C for 10min, and the supernata...

Embodiment 2

[0034] A kind of asparagus non-agar oligosaccharide, its preparation method is as follows:

[0035] (1) Asparagus is washed, desalted, dried, crushed and passed through a 4-mesh sieve, added with 2% sulfuric acid solution with a volume ratio 2 times that of Asparagus, bathed in 80°C for 80 minutes, filtered, discarding the filtrate, and drying the algae;

[0036] (2) Add 8 times the volume of distilled water to the obtained algae and extract twice by ultrasonic method, the ultrasonic power is 180-420W, the extraction temperature is 45-75°C, and the extraction time is 60-120 minutes; filter and combine the filtrates;

[0037] (3) The filtrate was concentrated to a relative density of 1.85 by vacuum distillation, refrigerated at 4°C for 7h, centrifuged at 1500rpm / min at 4°C for 8min, and the colloid was separated;

[0038] (4) The colloid was frozen in a -70°C freezer for 6 hours, placed at 4°C for 5 hours to thaw, centrifuged at 1500rpm / min, 4°C for 8min, and the supernatant wa...

Embodiment 3

[0042] A kind of asparagus non-agar oligosaccharide, its preparation method is as follows:

[0043] (1) Asparagus is washed, desalted, dried, crushed and passed through a 4-mesh sieve, added with 1% sulfuric acid solution with a volume ratio 5 times that of Asparagus, bathed in 90°C water for 70 minutes, filtered, the filtrate is discarded, and the algae are dried in the air;

[0044] (2) Add 6 times the volume of distilled water to the obtained algae and extract twice by ultrasonic method, the ultrasonic power is 180-420W, the extraction temperature is 45-75°C, and the extraction time is 60-120 minutes; filter and combine the filtrates;

[0045] (3) The filtrate was concentrated to a relative density of 1.60 by vacuum distillation, refrigerated at 4°C for 8h, centrifuged at 1500rpm / min, and centrifuged at 4°C for 12min, and the colloid was separated;

[0046] (4) The colloid was frozen in a freezer at -50°C for 4 hours, thawed at 4°C for 4 hours, centrifuged at 1500rpm / min, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com