A kind of amino retanning and fatliquoring agent and preparation method thereof

A retanning, fatliquoring and amino technology, applied in the chemical field, can solve problems such as few researches, and achieve the effects of high absorption efficiency, good softness and surface feel, and good retanning and filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

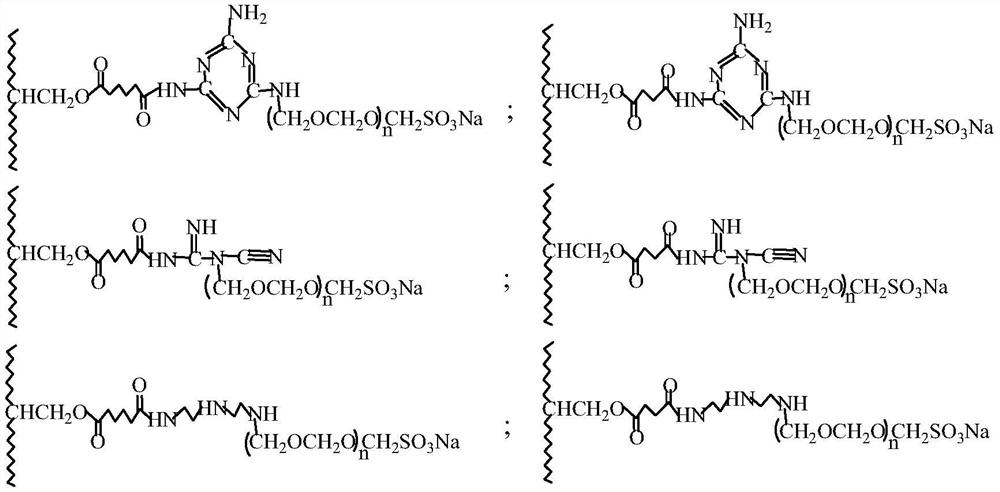

Method used

Image

Examples

Embodiment 1

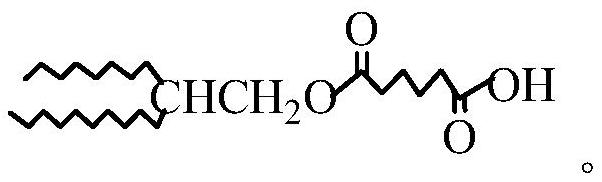

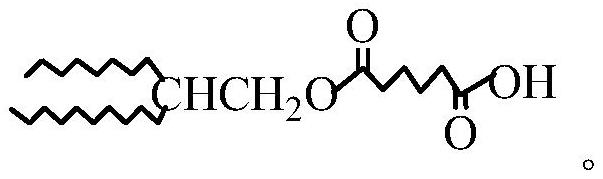

[0036] a. Esterification reaction. Add 120 parts of Guerbet alcohol and 76 parts of adipic acid into a 1000 mL reactor I equipped with a thermometer, a stirring device and a reflux condenser, raise the temperature to 180°C, and stir evenly. Then add 3 parts of p-toluenesulfonic acid, under the condition of negative pressure of -0.04MPa, react by timing for 6 hours to obtain Guerbet alcohol adipate. b. Amidation reaction. Lower the temperature of the reactor I to 100°C, add 72 parts of melamine in three batches, and control the temperature of the reactor to 100-120°C. After adding melamine, add 5 parts of sodium fluoride, stir evenly, raise the temperature to 130°C and react for 0.5 hours. Continue to heat up to 180°C, and keep the temperature for 2 hours. c. Preparation of sodium hydroxymethanesulfonate solution. Add 63 parts of sodium metabisulfite and 85 parts of deionized water into the 1000 mL reaction kettle II equipped with a thermometer and a stirring device, and st...

Embodiment 2

[0038]a. Esterification reaction. Add 120 parts of Guerbet alcohol and 62 parts of succinic acid into a 1000 mL reactor I equipped with a thermometer, a stirring device and a reflux condenser, raise the temperature to 160°C, and stir evenly. Then add 3.6 parts of p-toluenesulfonic acid, under the condition of -0.04MPa negative pressure, timed reaction for 6 hours to obtain Guerbet alcohol succinate. b. Amidation reaction. Lower the temperature of the reactor I to 100°C, add 72 parts of melamine in three batches, and control the temperature of the reactor to 100-120°C. After adding melamine, add 5 parts of sodium fluoride, stir evenly, raise the temperature to 130°C and react for 0.5 hours. Continue to heat up to 160°C, and keep the temperature for 3 hours. c. Preparation of sodium hydroxymethanesulfonate solution. Add 63 parts of sodium metabisulfite and 85 parts of deionized water into the 1000 mL reaction kettle II equipped with a thermometer and a stirring device, and s...

Embodiment 3

[0040] a. Esterification reaction. Add 120 parts of Guerbet alcohol and 68 parts of adipic acid into a 1000 mL reactor I equipped with a thermometer, a stirring device and a reflux condenser, raise the temperature to 160°C, and stir evenly. Then add 2.8 parts of p-toluenesulfonic acid, under the condition of negative pressure of -0.04MPa, react by timing for 6 hours to obtain Guerbet alcohol adipate. b. Amidation reaction. Cool the reactor I to 100°C, add 45 parts of dicyandiamide in three batches, and control the temperature of the reactor to 100-120°C. After adding dicyandiamide, add 4.5 parts of sodium fluoride, stir evenly, raise the temperature to 130°C and react for 0.5 hours. Continue to heat up to 180° C., and keep the temperature for 3 hours. c. Preparation of sodium hydroxymethanesulfonate solution. Add 58 parts of sodium metabisulfite and 78 parts of deionized water into the 1000mL reaction kettle II equipped with a thermometer and a stirring device, and stir ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com