FeCoNi-based soft magnetic high-entropy alloy and application thereof

A high-entropy alloy and soft magnetic technology, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of poor mechanical properties and magnetic properties of magnetic materials, loose and other problems, and achieve good strip formability, loose annealing conditions, Good comprehensive soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

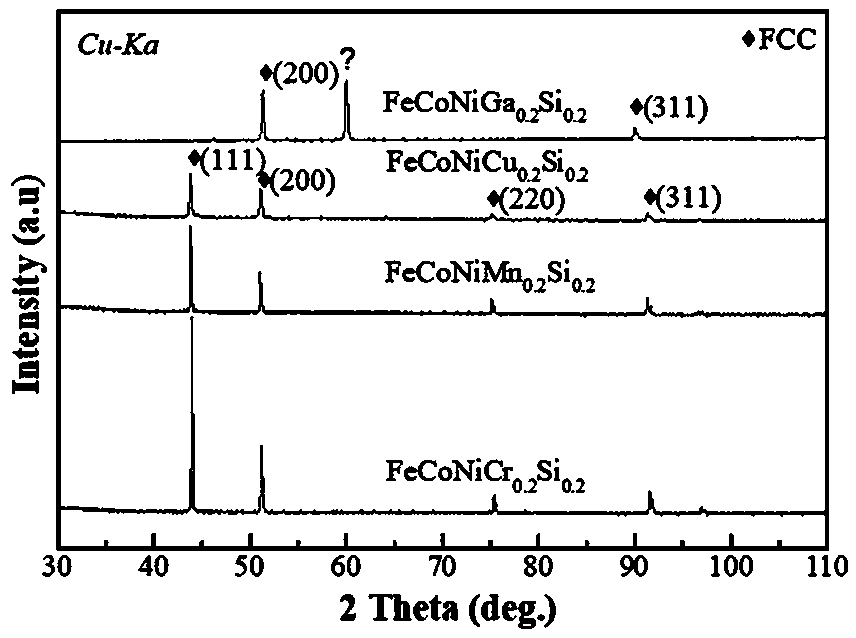

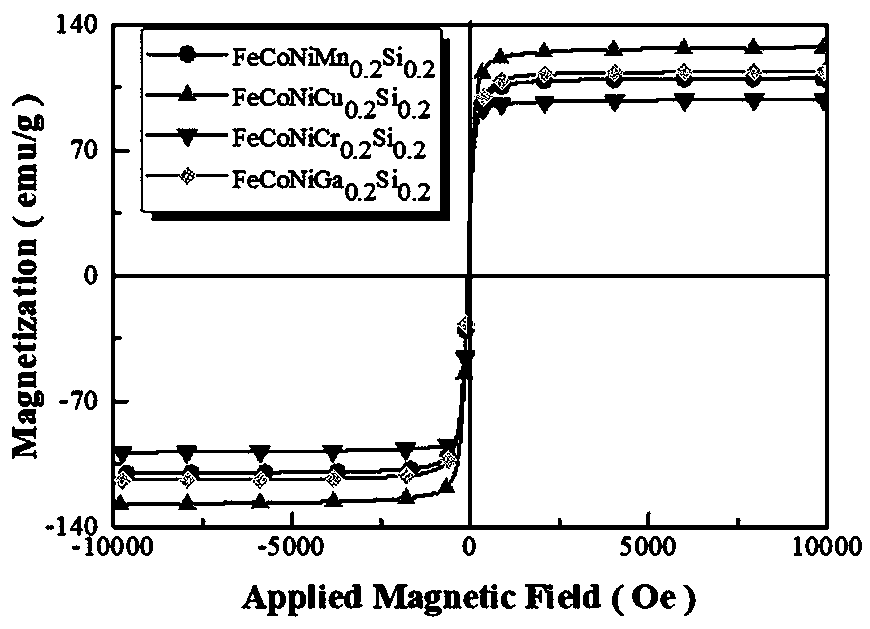

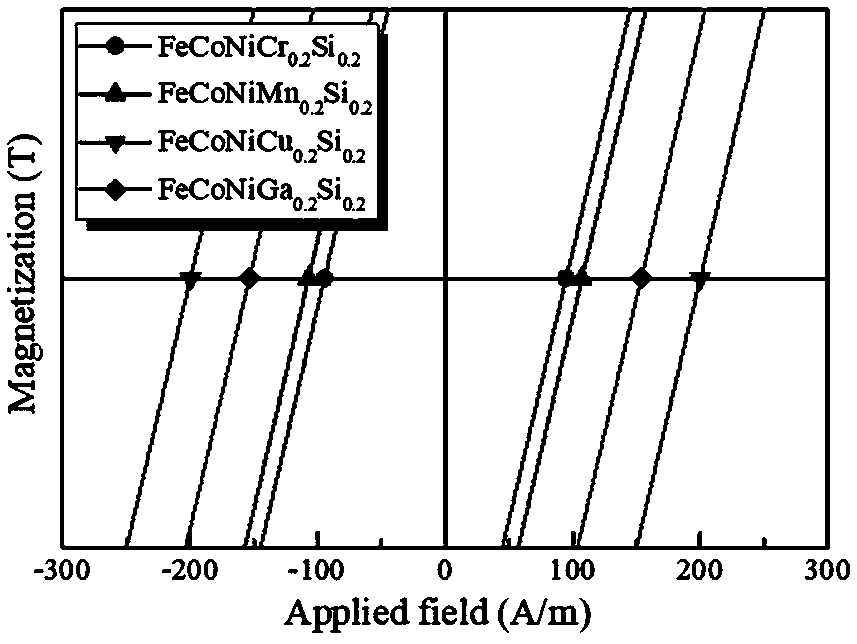

[0035] A FeCoNi-based soft magnetic high-entropy alloy Fe 29.42 co 29.41 Ni 29.41 Si 5.88 Cr 5.88 (at%), as a more detailed example, its preparation method includes the following steps:

[0036] (1) Ingredients: select Fe with a purity of 99.9wt%, Co with a purity of 99.99wt%, Ni with a purity of 99.99wt%, Si with a purity of 99.99wt%, and Cr with a purity of 99.99wt%, expressed according to the above alloy Before weighing the raw materials, remove the oxide film on the raw materials with sandpaper or a grinder, then put Fe, Co, Ni and other raw materials into a beaker filled with absolute ethanol, and perform ultrasonic cleaning for 250S. Then dry it completely with a hair dryer;

[0037] (2) Melting the master alloy: Put the prepared master alloy components into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, put the alloy elements with high density and high melting point on it, first use the mechanical pump to vacuum the furnace cavit...

Embodiment 2

[0040] A FeCoNi-based soft magnetic high-entropy alloy Fe 29.42 co 29.41 Ni 29.41 Si 5.88 mn 5.88 (at%), as a more detailed example, its preparation method includes the following steps:

[0041] (1) Ingredients: select Fe with a purity of 99.9wt%, Co with a purity of 99.99wt%, Ni with a purity of 99.99wt%, Si with a purity of 99.99wt%, and Mn with a purity of 99.99wt%, according to the above alloy expression Before weighing the raw materials, remove the oxide film on the raw materials with sandpaper or a grinder, then put Fe, Co, Ni and other raw materials into a beaker filled with absolute ethanol, and perform ultrasonic cleaning for 250S. Then dry it completely with a hair dryer;

[0042] (2) Melting the master alloy: Put the prepared master alloy components into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, put the alloy elements with high density and high melting point on it, first use the mechanical pump to vacuum the furnace cavi...

Embodiment 3

[0045] A FeCoNi-based soft magnetic high-entropy alloy Fe 29.42 co 29.41 Ni 29.41 Si 5.88 Cu 5.88 (at%), as a more detailed example, its preparation method includes the following steps:

[0046] (1) Ingredients: select Fe with a purity of 99.9wt%, Co with a purity of 99.99wt%, Ni with a purity of 99.99wt%, Si with a purity of 99.99wt%, and Cu with a purity of 99.99wt%, according to the above alloy expression Before weighing the raw materials, remove the oxide film on the raw materials with sandpaper or a grinder, then put Fe, Co, Ni and other raw materials into a beaker filled with absolute ethanol, and perform ultrasonic cleaning for 250S. Then dry it completely with a hair dryer;

[0047] (2) Melting the master alloy: Put the prepared master alloy components into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, put the alloy elements with high density and high melting point on it, first use the mechanical pump to vacuum the furnace cavi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com