Aluminum-based coating and preparation method thereof, and aluminum alloy composite material prepared from aluminum-based coating and preparation method of aluminum alloy composite material

A technology of aluminum-based coatings and composite materials, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem of coating wear resistance, hardness, interface strength and other properties that are difficult to preset and control, and affect the coating Problems such as connection strength and short service life, to improve wear resistance and hardness, excellent forming effect, and excellent matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

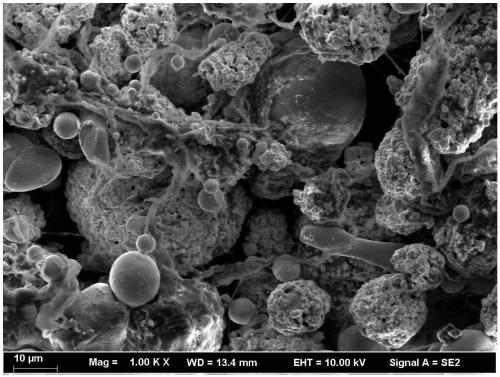

Image

Examples

Embodiment 1

[0028] The aluminum-based coating raw materials include the following raw materials: 30% Ni-SiC powder, 45% 6061 aluminum alloy powder, 21% Al-Si-Cu powder and 4% silicone resin binder. Wherein, the mass fraction of Si in the Al-Si-Cu powder may be 6.0%, the mass fraction of Cu may be 28%, and the balance may be Al. The silicone resin binder includes the following raw materials: 38.8% polytetrafluoroethylene, 22.5% methyltriethoxysilane, 8.5% fluororubber, 3.3% maleic anhydride, 5.2% styrene-butadiene rubber, 0.8% polyaldehyde Resin, 8.8% Talc, 6.7% Acrylic Rubber, 4.2% Polycarbonate, 1.2% Hydroxy Dimethicone.

[0029] The preparation method of aluminum-based coating comprises the steps:

[0030] (1) Take Ni-SiC powder, 6061 aluminum alloy powder, Al-Si-Cu powder by mass percentage, and mix them;

[0031] (2) Put the mixture into an automatic stirring equipment container, and add a silicone resin binder, then close the container, and stir to obtain a uniform mixture;

[003...

Embodiment 2

[0041] The aluminum-based coating material includes the following raw materials: 60% Ni-SiC powder, 15% 6061 aluminum alloy powder, 23% Al-Si-Cu powder and 2% silicone resin binder. Wherein, the mass fraction of Si in the Al-Si-Cu powder is 11.7%, the mass fraction of Cu is 5%, and the balance is Al. The raw material of the silicone resin binder is the same as in Example 1.

[0042] The preparation method of aluminum-based coating comprises the steps:

[0043] (1) Take Ni-SiC powder, 6061 aluminum alloy powder, Al-Si-Cu powder by mass percentage, and mix them;

[0044] (2) Put the mixture into an automatic stirring equipment container, and add a silicone resin binder, then close the container, and stir to obtain a uniform mixture;

[0045] (3) Roll the mixed metal powder particles obtained in step (2) on the automatic roll equipment. First, adjust the distance between the roll and the workbench, control the thickness of the bonding cloth at about 3.0-5.0 mm, and perform prel...

Embodiment 3

[0054] The aluminum-based coating raw materials include the following raw materials: 45% Ni-SiC powder, 30% 6061 aluminum alloy powder, 22% Al-Si-Cu powder and 3% organic silicon resin binder. Wherein, the mass fraction of Si in the Al-Si-Cu powder is 10%, the mass fraction of Cu may be 24%, and the balance is Al. The silicone resin binder raw material is the same as in Example 1.

[0055] The preparation method of aluminum-based coating comprises the steps:

[0056] (1) Take Ni-SiC powder, 6061 aluminum alloy powder, Al-Si-Cu powder by mass percentage, and mix them;

[0057] (2) Put the mixture into an automatic stirring equipment container, and add a silicone resin binder, then close the container, and stir to obtain a uniform mixture;

[0058] (3) Roll the mixed metal powder particles obtained in step (2) on the automatic roll equipment. First, adjust the distance between the roll and the workbench, control the thickness of the bonding cloth at about 3.0-5.0 mm, and perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com