Silicon carbon cathode material and preparation method thereof, power battery and electric vehicle

A technology for negative electrode materials and power batteries, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low cycle performance and rate performance of silicon carbon negative electrode materials, which need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

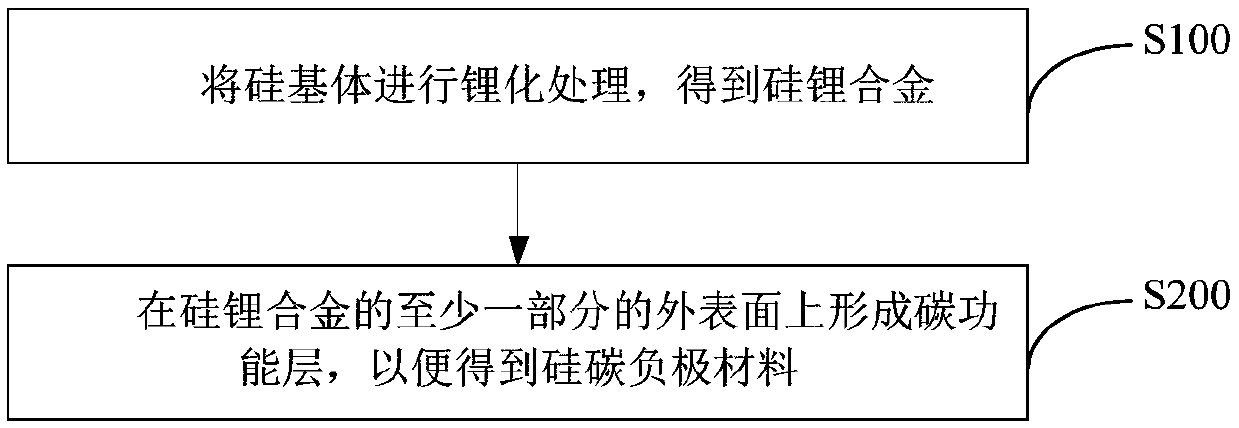

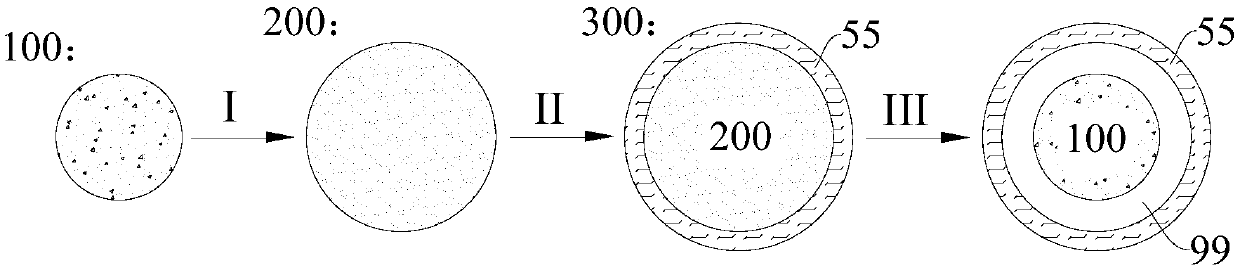

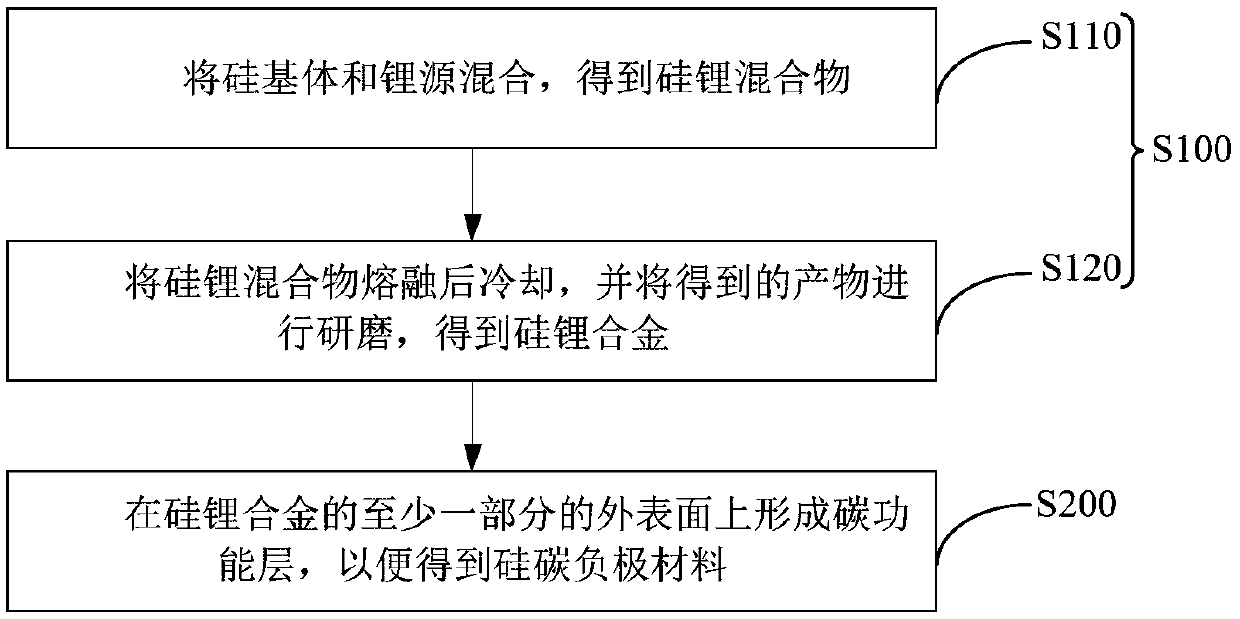

Method used

Image

Examples

Embodiment 1

[0083] Mix a lithium source with a mass ratio of 0.78:1 and a silicon matrix to obtain a silicon-lithium mixture; heat the silicon-lithium mixture to 750°C for 1 hour, then cool to room temperature, and grind the obtained product to obtain a granular powder. Silicon-lithium alloy (particle size is 300nm); Silicon-lithium alloy is dispersed in isopropanol to obtain a silicon-lithium alloy dispersion with a mass concentration of 142g / L; graphene oxide is dispersed in isopropanol to obtain a mass concentration of 2g / L carbon source dispersion; mix the silicon-lithium alloy dispersion and the carbon source dispersion in a volume ratio of 1:1 to obtain a silicon-carbon mixed dispersion; filter the silicon-carbon mixed dispersion, and The filtered residue was freeze-dried to obtain a solid dispersion; the solid dispersion was heated to 500°C at a heating rate of 10°C / min and then kept for 1h; then heated to 800°C at a heating rate of 10°C / min and then kept for 4h; Then the temperatu...

Embodiment 2

[0086] Mix a lithium source with a mass ratio of 0.9:1 and a silicon matrix to obtain a silicon-lithium mixture; heat the silicon-lithium mixture to 850°C for 1.5 hours, then cool to room temperature, and grind the obtained product to obtain a granular powder The silicon-lithium alloy (particle size is 450nm); the silicon-lithium alloy is dispersed in isopropanol to obtain a silicon-lithium alloy dispersion with a mass concentration of 142g / L; the graphene oxide is dispersed in isopropanol to obtain a mass concentration of It is a 3g / L carbon source dispersion; mix the silicon-lithium alloy dispersion and the carbon source dispersion in a volume ratio of 1:1 to obtain a silicon-carbon mixed dispersion; filter the silicon-carbon mixed dispersion, and The filtered residue was freeze-dried to obtain a solid dispersion; the solid dispersion was heated to 500°C at a heating rate of 10°C / min and then kept for 1.5h; then heated to 800°C at a heating rate of 10°C / min and then kept warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com