Preparation method of liquid nisin

A nisin and liquid technology, applied in chemical instruments and methods, food preservation, food science, etc., can solve the problems of nisin instability, low extraction yield, cumbersome use, etc., to reduce energy consumption, Improve the product yield and improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Put the fermented nisin fermentation broth with a titer of 10000IU / mL into the foam separation tower, 3 The ventilation rate per hour is fed into compressed air with an outlet pressure of 0.2-0.4MPa for foam separation;

[0032] 2) Use a collector to collect the foam concentrate, and according to the condition of the foam in the collector, add a total amount of 0.001% to 0.005% (v / v) polyoxypropylene polyoxyethylene glyceryl ether defoamer to it for defoaming. Soaking treatment to obtain a 4-fold concentrated solution (more than 35,000 IU / mL titer);

[0033] 3) Add food-grade hydrochloric acid with a concentration of 30-32% (w / w) to the defoamed concentrated solution, and adjust its pH value to 2.0-3.0;

[0034] 4) Heat the concentrated solution after pH adjustment to 60-100°C in a water bath, and maintain it for 10-60 minutes;

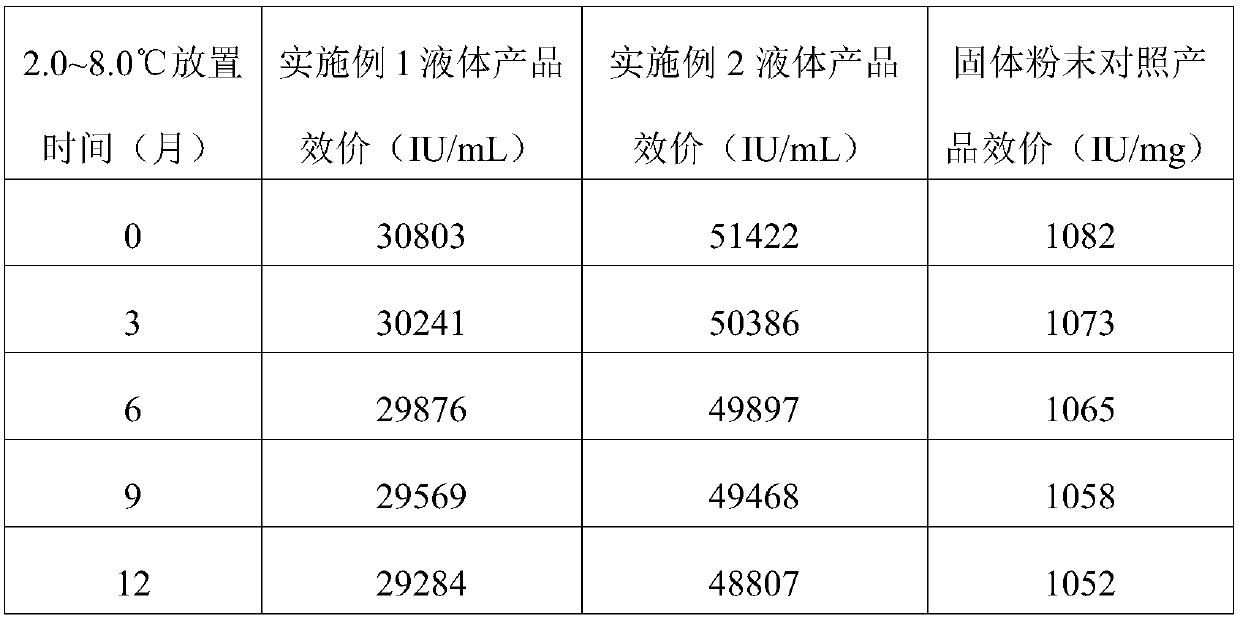

[0035] 5) Filtrate with a ceramic membrane with a cut-off pore size of 50-200 nm to obtain a ceramic membrane filtrate (potency above 30,...

Embodiment 2

[0039] 1) Put the fermented nisin fermented liquid with a titer of 9000IU / mL into the foam separation tower, and 3.0m from the bottom 3 The ventilation rate per hour is fed into compressed air with an outlet pressure of 0.2-0.4MPa for foam separation;

[0040] 2) Use a collector to collect the foam concentrate, and according to the condition of the foam in the collector, add a total amount of 0.001% to 0.005% (v / v) polyoxypropylene polyoxyethylene glyceryl ether defoamer to it for defoaming. Soaking treatment to obtain a 6-fold concentrated solution (more than 50,000 IU / mL titer);

[0041] 3) Add food-grade hydrochloric acid with a concentration of 30-32% (w / w) to the defoamed concentrated solution, and adjust its pH value to 2.0-3.0;

[0042] 4) Heat the concentrated solution after pH adjustment to 60-100°C in a water bath, and maintain it for 10-60 minutes;

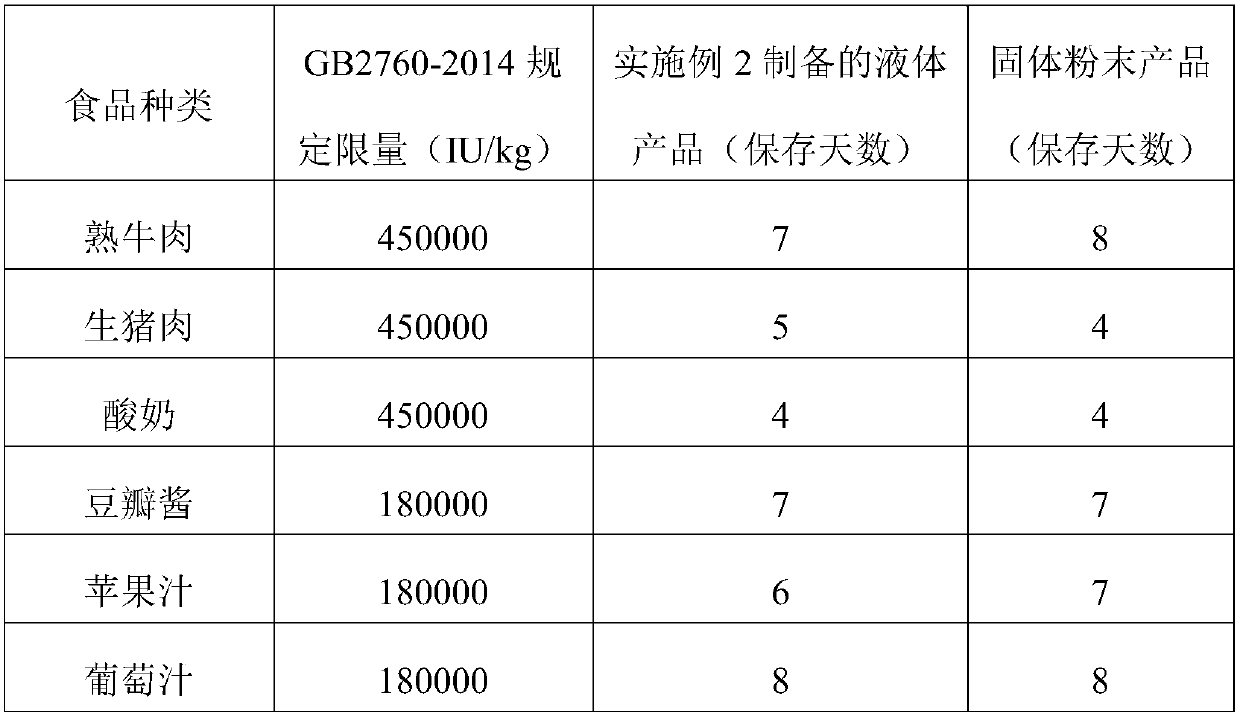

[0043] 5) Filtrate with a ceramic membrane with a cut-off pore size of 50-200 nm to obtain a ceramic membrane filtr...

Embodiment 3

[0047] 1) Put the fermented nisin fermentation broth with a titer of 8000IU / mL into the foam separation tower, 3 The ventilation rate per hour is fed into compressed air with an outlet pressure of 0.2-0.4MPa for foam separation;

[0048]2) Use a collector to collect the foam concentrate, and according to the condition of the foam in the collector, add a total amount of 0.001% to 0.005% (v / v) polyoxypropylene polyoxyethylene glyceryl ether defoamer to it for defoaming. Soaking treatment to obtain concentrated 8-fold concentrated solution (titer 65000IU / mL or more);

[0049] 3) Add food-grade hydrochloric acid with a concentration of 30-32% (w / w) to the defoamed concentrated solution, and adjust its pH value to 2.0-3.0;

[0050] 4) Heat the concentrated solution after pH adjustment to 60-100°C in a water bath, and maintain it for 10-60 minutes;

[0051] 5) Filtrate with a ceramic membrane with a cut-off pore size of 50-200 nm to obtain a ceramic membrane filtrate (a potency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com