A kind of preparation device and preparation method of dha algae oil nano liposome

A technology for preparing nano-liposomes and devices, applied in liposome delivery, chemical instruments and methods, food ingredients containing gas, etc., can solve problems such as complex exhaust process, device pressure imbalance, and affecting work process Good storage stability, reduced oxidation, and protection from oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of DHA algal oil nano liposome, concrete steps are as follows:

[0023] In the first step, mix 100kg soybean lecithin and 50-55kg DHA algae oil, stir until completely dissolved, and obtain phospholipid phase feed liquid; dissolve 10-12kg sodium caseinate in 5000-5200L drinking water, stir at medium temperature until completely dissolved , to obtain the aqueous phase feed solution;

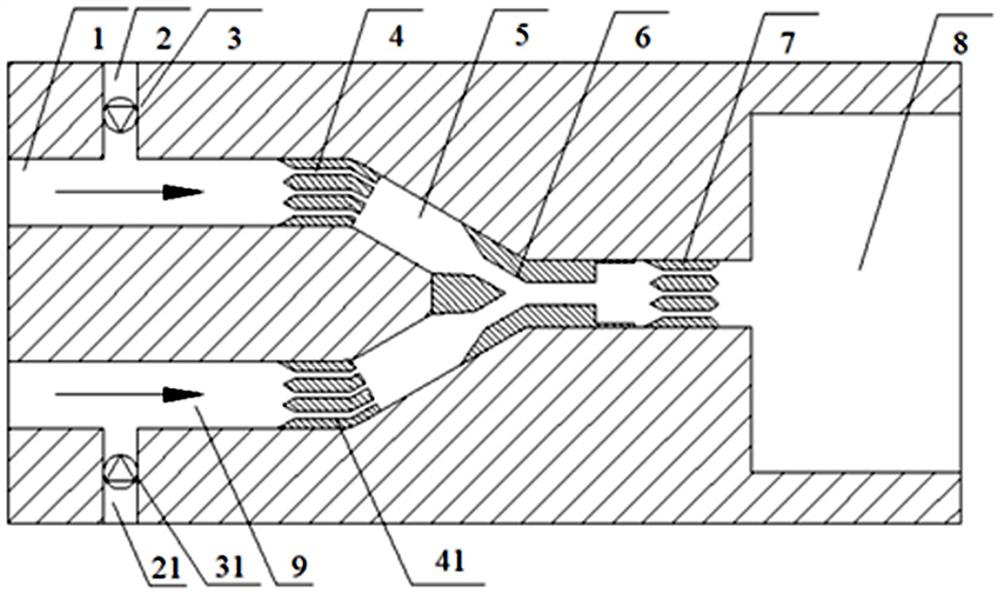

[0024] In the second step, the carbon dioxide is introduced into the jet reaction chamber through the inlet channels 2 and 21, and the inlet valves 3 and 31 can control the inlet pressure and speed; at the same time, the phospholipid phase material liquid is introduced into the gas-assisted jet reaction chamber by using a high pressure of 80-90Mpa In the feed splitting area 1, a high pressure of 80-90Mpa is used to introduce the aqueous phase feed liquid into the feed splitting area 9; driven by the high pressure, the gas and the liquid pass through the microporo...

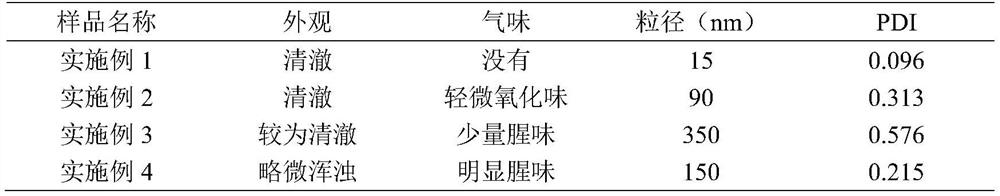

Embodiment 1

[0026]1. Weigh 100kg of soybean lecithin and 50kg of DHA algae oil, heat and stir until completely dissolved to obtain the phospholipid phase feed solution. Measure 5000L of drinking water, add 10kg of sodium caseinate, stir and heat until completely dissolved to obtain an aqueous phase feed solution. 2. Introduce carbon dioxide into the jet reaction chamber through the intake channels 2 and 21, and the intake valves 3 and 31 can control the intake pressure and speed; at the same time, the phospholipid phase feed liquid is introduced into the feed diversion area of the gas-assisted jet reaction chamber with a high pressure of 80Mpa 1. Use 80Mpa high pressure to introduce the aqueous phase feed liquid into the feed splitting area 9 to obtain DHA algae oil nano-liposomes, and detect the physical and chemical properties.

Embodiment 2

[0028] 1. Weigh 100kg of soybean lecithin and 50kg of DHA algae oil, heat and stir until completely dissolved to obtain the phospholipid phase feed liquid. Measure 5000L of drinking water, add 10kg of sodium caseinate, stir and heat until completely dissolved to obtain an aqueous phase feed solution. 2. Use 80Mpa high pressure to introduce the phospholipid phase feed liquid into the feed split area 1 of the gas-assisted jet reaction chamber, and use 80Mpa high pressure to introduce the water phase feed liquid into the feed split area 9 to prepare DHA algae oil nano liposomes and detect the physical and chemical properties .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com