Production method of high-chromogenic-power enamel titanium dioxide for pigment by sulfuric acid method

A production method, the technology of sulfuric acid method, applied in the direction of chemical instruments and methods, titanium dioxide, titanium compounds, etc., can solve the problems of low hydrolysis concentration, reduced production efficiency, low product qualification rate, etc., achieve uniform particle size, accelerate cooling speed, Favorable Effects for Consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

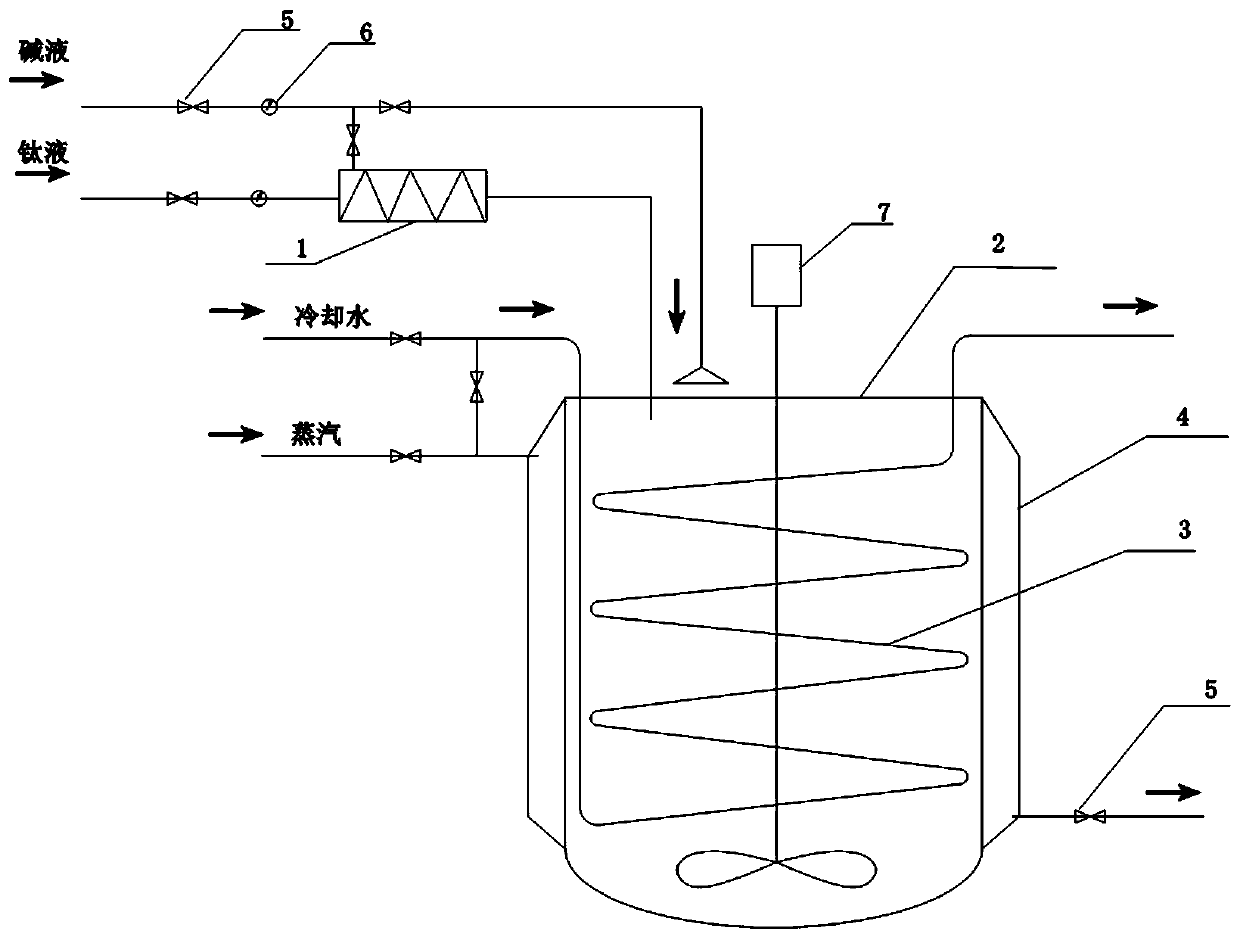

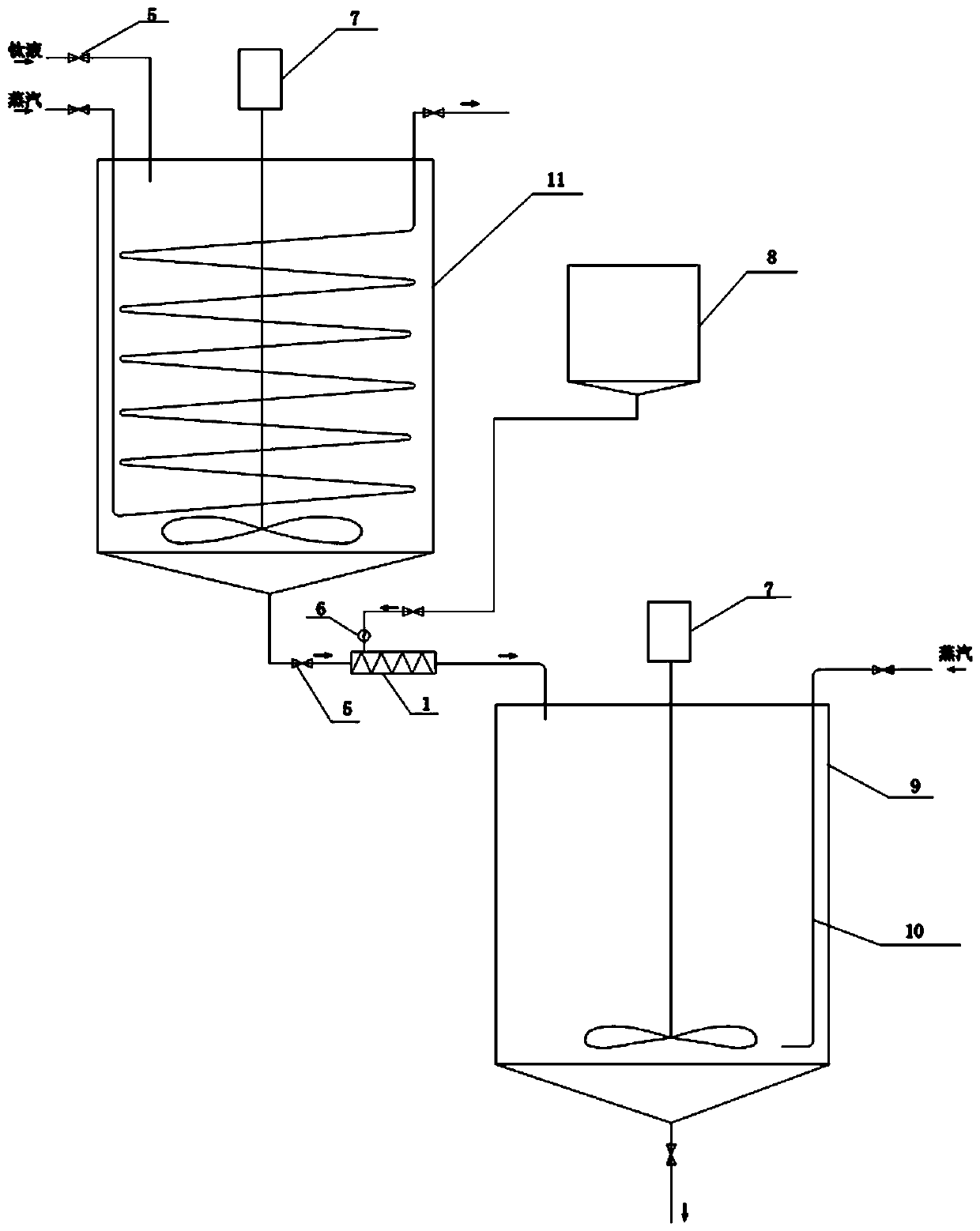

[0040] A kind of production method of sulfuric acid method enamel titanium dioxide with high color developing power for pigment, comprises the following steps:

[0041] (1) Production of hydrolysis seed crystals: first mix titanium solution with a titanium concentration of 130g / L and an effective acid content of 250g / L, and a sodium hydroxide solution with a mass percentage of 10%, according to titanium solution: sodium hydroxide The solution is added to the static mixer at the flow ratio of 1:0.7 at the same time, and the titanium liquid and the sodium hydroxide solution are quickly mixed. The static mixer is used to quickly mix the titanium liquid and the liquid caustic soda, which avoids the occurrence of excessive local alkalinity. Ferrous hydroxide affects the purity of the seed crystals, which solves the problem that the lye cannot be added quickly. The conditions for the formation of the seed crystals are more consistent, and the quality of the seed crystals is better; ...

Embodiment 2

[0046] A kind of production method of sulfuric acid method enamel titanium dioxide with high color developing power for pigment, comprises the following steps:

[0047] (1) Production of hydrolysis seed crystals: first mix titanium solution with a titanium concentration of 135g / L and an effective acid content of 260g / L, and a sodium hydroxide solution with a mass percentage of 12%, according to titanium solution: sodium hydroxide The solution is added to the static mixer at the flow ratio of 1:0.7 at the same time, and the titanium liquid and the sodium hydroxide solution are quickly mixed. The static mixer is used to quickly mix the titanium liquid and the liquid caustic soda, which avoids the occurrence of excessive local alkalinity. Ferrous hydroxide affects the purity of the seed crystals, which solves the problem that the lye cannot be added quickly. The conditions for the formation of the seed crystals are more consistent, and the quality of the seed crystals is better; ...

Embodiment 3

[0052] A kind of production method of sulfuric acid method enamel titanium dioxide with high color developing power for pigment, comprises the following steps:

[0053](1) Production of hydrolysis seed crystals: first mix titanium solution with a titanium concentration of 138g / L and an effective acid content of 265g / L, and a sodium hydroxide solution with a mass percentage of 14%, according to titanium solution: sodium hydroxide The solution is added to the static mixer at the flow ratio of 1:0.7 at the same time, and the titanium liquid and the sodium hydroxide solution are quickly mixed. The static mixer is used to quickly mix the titanium liquid and the liquid caustic soda, which avoids the occurrence of excessive local alkalinity. Ferrous hydroxide affects the purity of the seed crystals, which solves the problem that the lye cannot be added quickly. The conditions for the formation of the seed crystals are more consistent, and the quality of the seed crystals is better; T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com