Pure fresh fructus zanthoxyli oil and production process thereof

A production process and technology of pure pepper oil, applied in the field of pure flower pepper oil and its production technology, can solve the problems of easy pollution, high labor intensity, long processing time, etc., and achieve high food safety, high degree of automation, and equipment investment. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

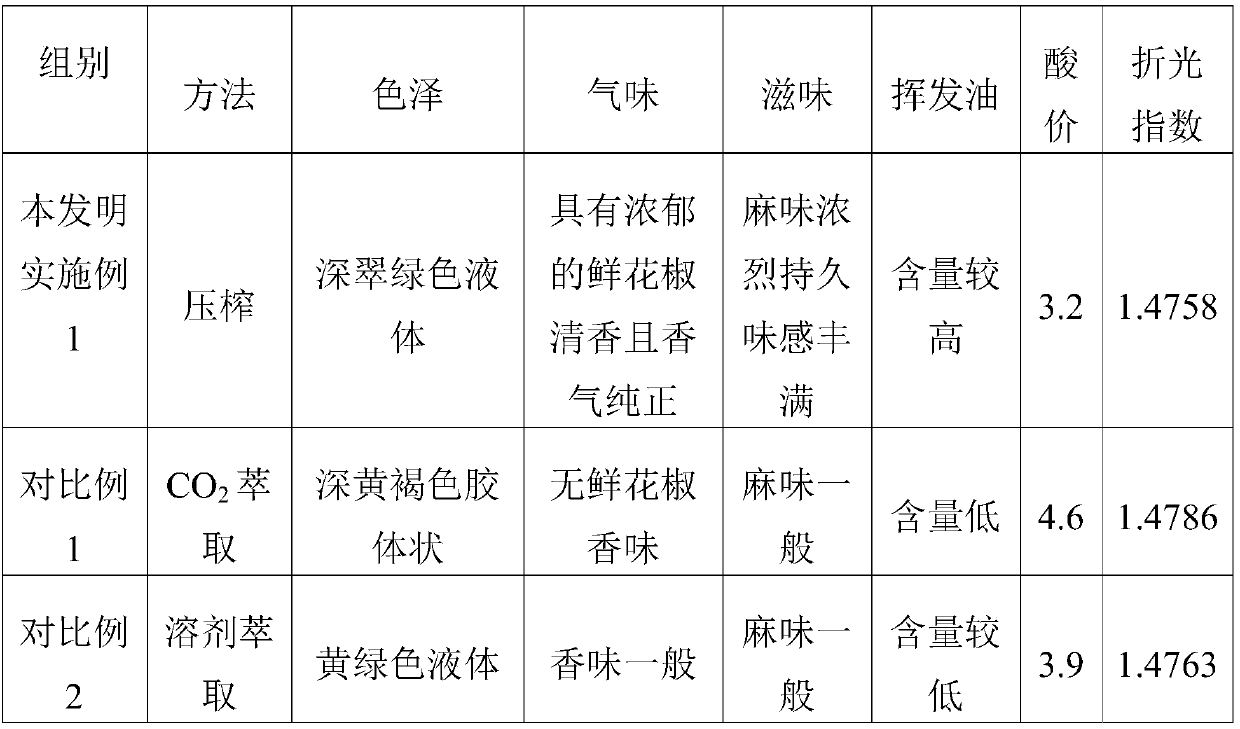

Examples

Embodiment 1

[0044] A production process of original ecological high-concentration prickly ash oil, the steps are as follows:

[0045] a. Raw materials: freshly picked fresh pepper fruits, selected to remove impurities, hair, metal, stones and other foreign objects.

[0046] b. Cleaning of raw materials: remove dust, pesticide residues, and heavy metals from leaves.

[0047] c. Destemming and separation: use the pepper destemming equipment to remove the branches and stems of the pepper, and separate to obtain the pure fruit of the pepper.

[0048] d. Preparation of Zanthoxylum bungeanum crude oil juice: the net fruit of Zanthoxylum bungeanum obtained in step c is subjected to three-stage pressing with an extruder, the water content of the oil sac part of the Zanthoxylum bungeanum peel is 53%-57%, and the pressure of the first pressing is controlled at 1.2Mpa. 20 minutes; the pressure of the second pressing is controlled at 1.6Mpa, and the process is 10 minutes; the pressure of the third p...

Embodiment 2

[0056] A production process of original ecological high-concentration prickly ash oil, the steps are as follows:

[0057] a. Raw materials: freshly picked fresh pepper fruits, selected to remove impurities, hair, metal, stones and other foreign objects.

[0058] b. Cleaning of raw materials: remove dust, pesticide residues, and heavy metals from leaves.

[0059] c. Destemming and separation: use the pepper destemming equipment to remove the branches and stems of the pepper, and separate to obtain the pure fruit of the pepper.

[0060] d. Preparation of Zanthoxylum bungeanum crude oil juice: the net fruit of Zanthoxylum bungeanum obtained in step c is subjected to three-stage pressing with a press, the water content of the oil sac part of the Zanthoxylum bungeanum peel is 61%-70%, and the pressure of the first pressing is controlled at 1.0Mpa. 20 minutes; the pressure of the second pressing is controlled at 1.6Mpa, and the process is 10 minutes; the pressure of the third press...

Embodiment 3

[0068] A production process of original ecological high-concentration prickly ash oil, the steps are as follows:

[0069] a. Raw materials: freshly picked fresh pepper fruits, selected to remove impurities, hair, metal, stones and other foreign objects.

[0070] b. Cleaning of raw materials: remove dust, pesticide residues, and heavy metals from leaves.

[0071] c. Destemming and separation: use the pepper destemming equipment to remove the branches and stems of the pepper, and separate to obtain the pure fruit of the pepper.

[0072] d. Preparation of Zanthoxylum bungeanum crude oil juice: The net fruit of Zanthoxylum bungeanum obtained in step c is subjected to three-stage pressing with an extruder. The water content of the oil sac part of the Zanthoxylum bungeanum peel is 50%-60%, and the pressure of the first pressing is controlled at 1.2Mpa. 20 minutes; the pressure of the second pressing is controlled at 1.6Mpa, and the process is 10 minutes; the pressure of the third p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com