Nitrified fuel power conversion power plant

A power conversion and power plant technology, applied in the field of nitrified fuel power conversion power plants, can solve problems such as fear and danger, and achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

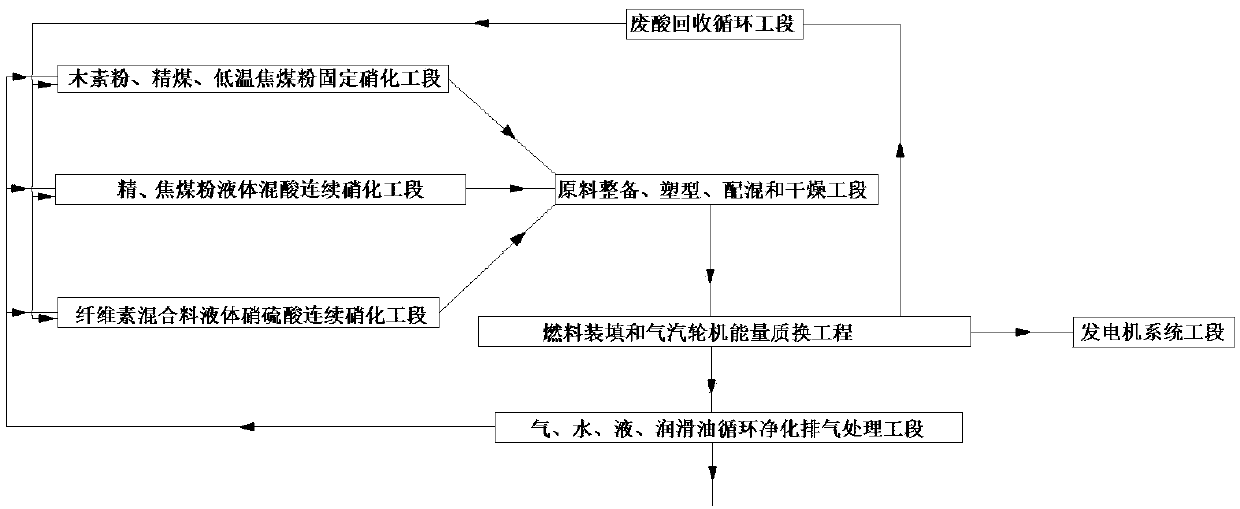

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0036] When the power plant in this embodiment generates electricity specifically, the flow process is as follows:

[0037] In the solid nitration section of lignin powder, clean coal, and low-temperature coking coal powder, lignin powder, coking coal powder, or other raw materials that are difficult to nitrate industrially are nitrated with solid and esterified nitrating agents, and the finished product It is nitrified wood powder, nitrified essence and coking coal powder; then the nitrified wood powder is transported to the nitrified wood powder bin by the first finished product transportation equipment, and the amount of nitrified wood powder transported to the nitrified wood powder bin is measured by the first meter Real-time monitoring, and the monitoring results are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com