Lithium ion battery current collector and preparation method thereof

A lithium-ion battery, current collector technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of low brittleness and toughness, poor product consistency, material waste, etc., to improve electrical conductivity, material The effect of less waste and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

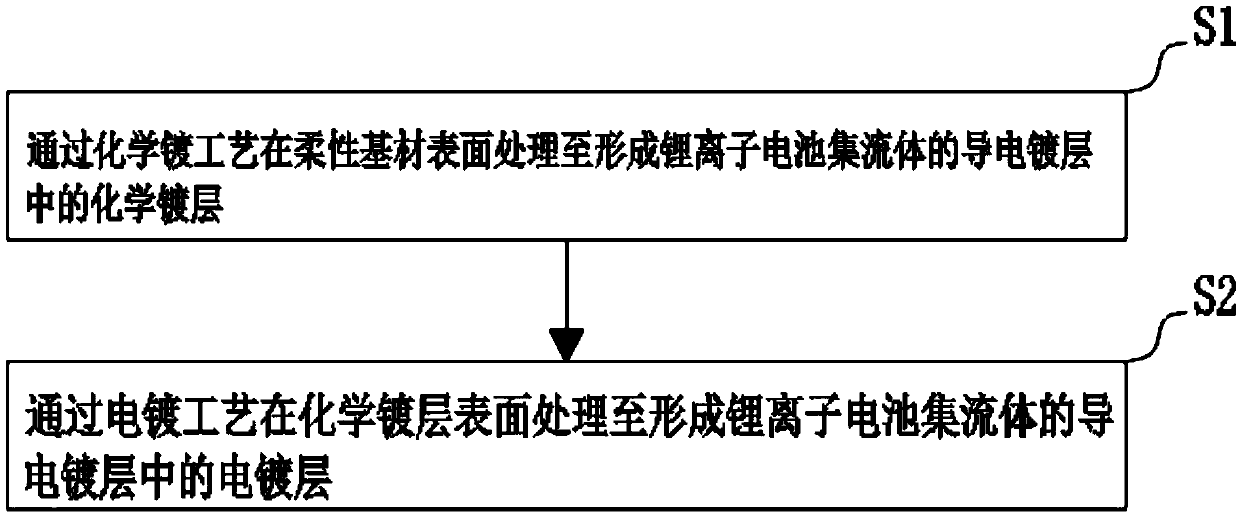

Method used

Image

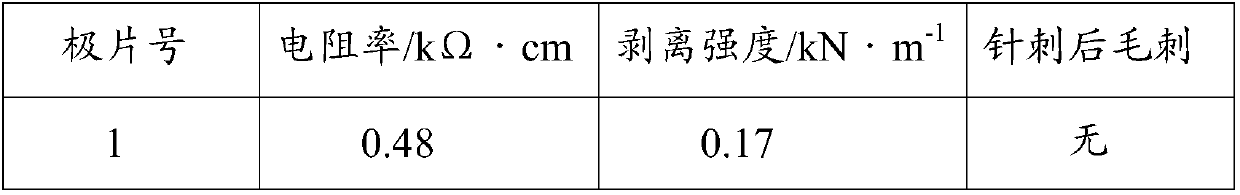

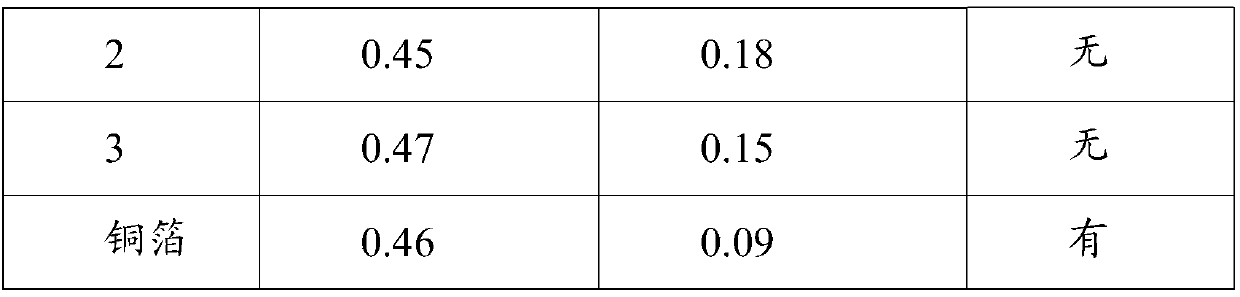

Examples

Embodiment

[0022] The lithium ion battery current collector of the present invention includes a flexible substrate and a conductive plating layer coated on the surface of the flexible substrate, and the conductive plating layer includes an electroless plating layer and an electroplating layer from the inside to the outside.

[0023] The flexible substrate is a flexible material capable of tensile deformation, high temperature resistance, and electrolyte corrosion resistance. The flexible substrate can be subjected to electroless plating and electroplating to obtain electroless plating and electroplating.

[0024] In this embodiment, the flexible substrate is a non-conductive flexible substrate.

[0025] The above-mentioned non-conductive flexible substrate includes at least one of polyethylene (PE), polypropylene (PP), polycarbonate (PC), glass fiber cloth, polyimide and polyester film. More specifically, the non-conductive flexible substrate may be one or a combination of polyethylene,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com