Lycium ruthenicum fruit extraction method and extract thereof

An extraction method and technology of Lycium rutabaga, applied in the field of extraction, can solve the problems of reduced flavor of the extract of Lycium rutabaga, higher equipment condition requirements, color degradation, etc., so as to avoid high temperature treatment process, improve product quality, and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Take 50g of fresh Lycium barbarum fruit, add 150g of distilled water, add 50mg of food-grade cellulase and 300mg of pectinase, and let stand at 30°C for 2 hours.

[0046] 2) Use a 200-mesh sieve to remove pomace by coarse filtration, and then use a plate filter to fine-filter, so that the average diameter of the particles is less than 1 μm.

[0047] 3) For fine filtration products, ceramic membranes with a pore size of 20nm are selected as the ultrafiltration membrane material, and the ultrafiltration process conditions are: temperature 25°C, pressure 1.0MPa.

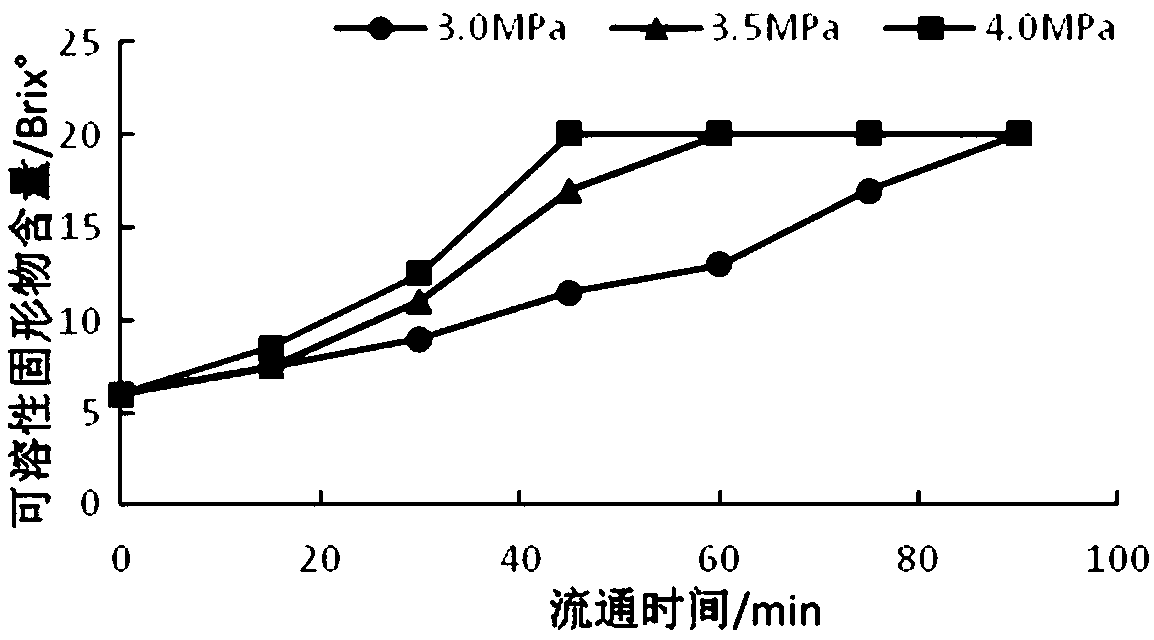

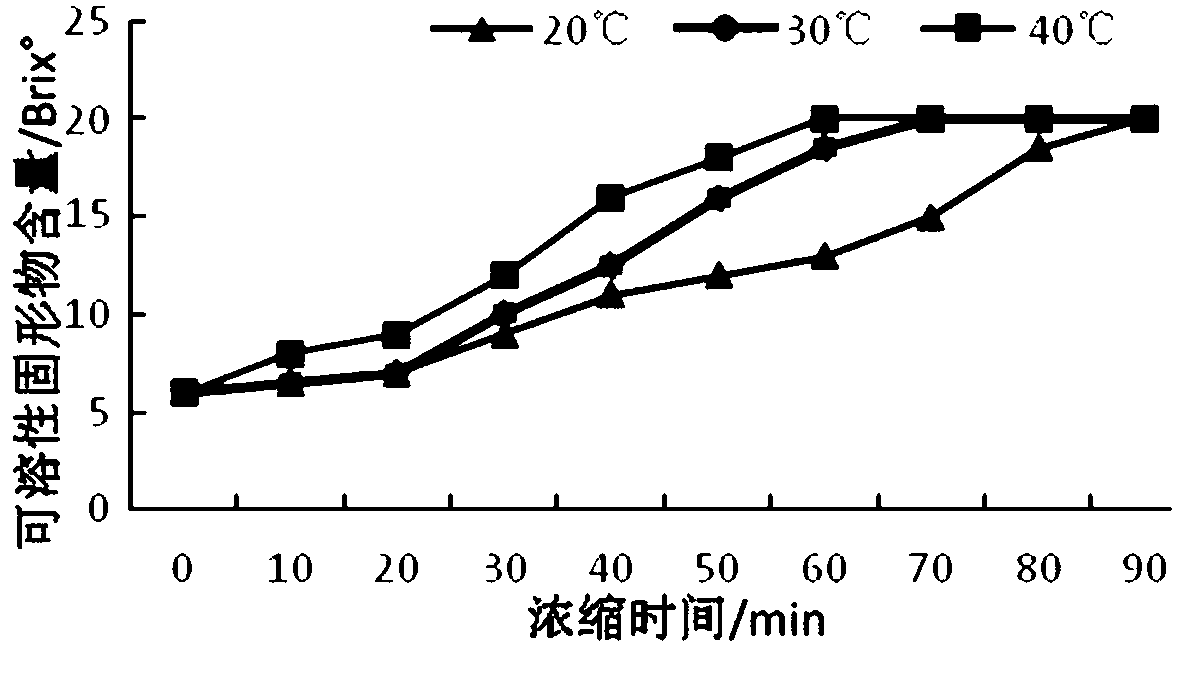

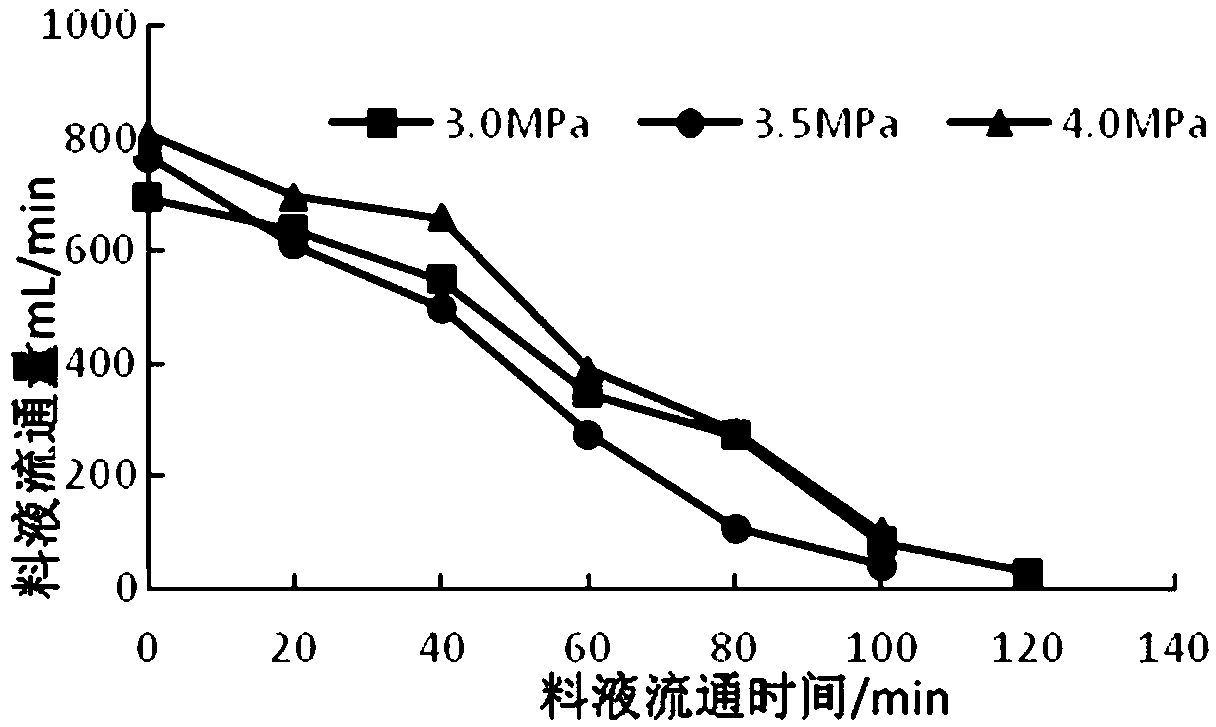

[0048] 4) The ultra-filtered clear juice is injected into the reverse osmosis equipment, and the reverse osmosis is carried out under the conditions of temperature 40°C and pressure 4.0MPa.

Embodiment 2

[0050] 1) Take 100g of fresh Lycium barbarum fruit, add 300g of distilled water, add 100mg of food-grade cellulase, 600mg of pectinase, and let stand at 30°C for 2 hours;

[0051] 2) After coarsely filtering the fruit juice with a 200-mesh sieve, use a plate filter to fine-filter it so that the average diameter of the particles is less than 1 μm;

[0052] 3) For fine filtration products, ceramic membranes with a pore size of 20nm are selected as the ultrafiltration membrane material, and the optimal ultrafiltration process conditions are: temperature 25°C, pressure 1.0MPa;

[0053] 4) The ultra-filtered clear juice is injected into the reverse osmosis equipment, and the reverse osmosis is carried out under the conditions of temperature 40°C and pressure 4.0MPa.

Embodiment 3

[0055] 1) Take 50kg of fresh Lycium barbarum fruit, add 150Kg of distilled water, add 50g of food-grade cellulase and 300g of pectinase, and let stand at 30°C for 2 hours;

[0056] 2) After coarsely filtering the fruit juice with a 200-mesh sieve, use a plate filter to fine-filter it so that the average diameter of the particles is less than 1 μm;

[0057] 3) For fine filtration products, ceramic membranes with a pore size of 20nm are selected as the ultrafiltration membrane material, and the optimal ultrafiltration process conditions are: temperature 25°C, pressure 1.0MPa;

[0058] 4) The ultra-filtered clear juice is injected into the reverse osmosis equipment, and the reverse osmosis is carried out under the conditions of temperature 40°C and pressure 4.0MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com