Treatment system for waste gas from plastic residues

A technology for waste gas treatment and slag, which is applied in the directions of air quality improvement, smoke removal, and dispersed particle separation. Threat of personal injury, good effect of collecting gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

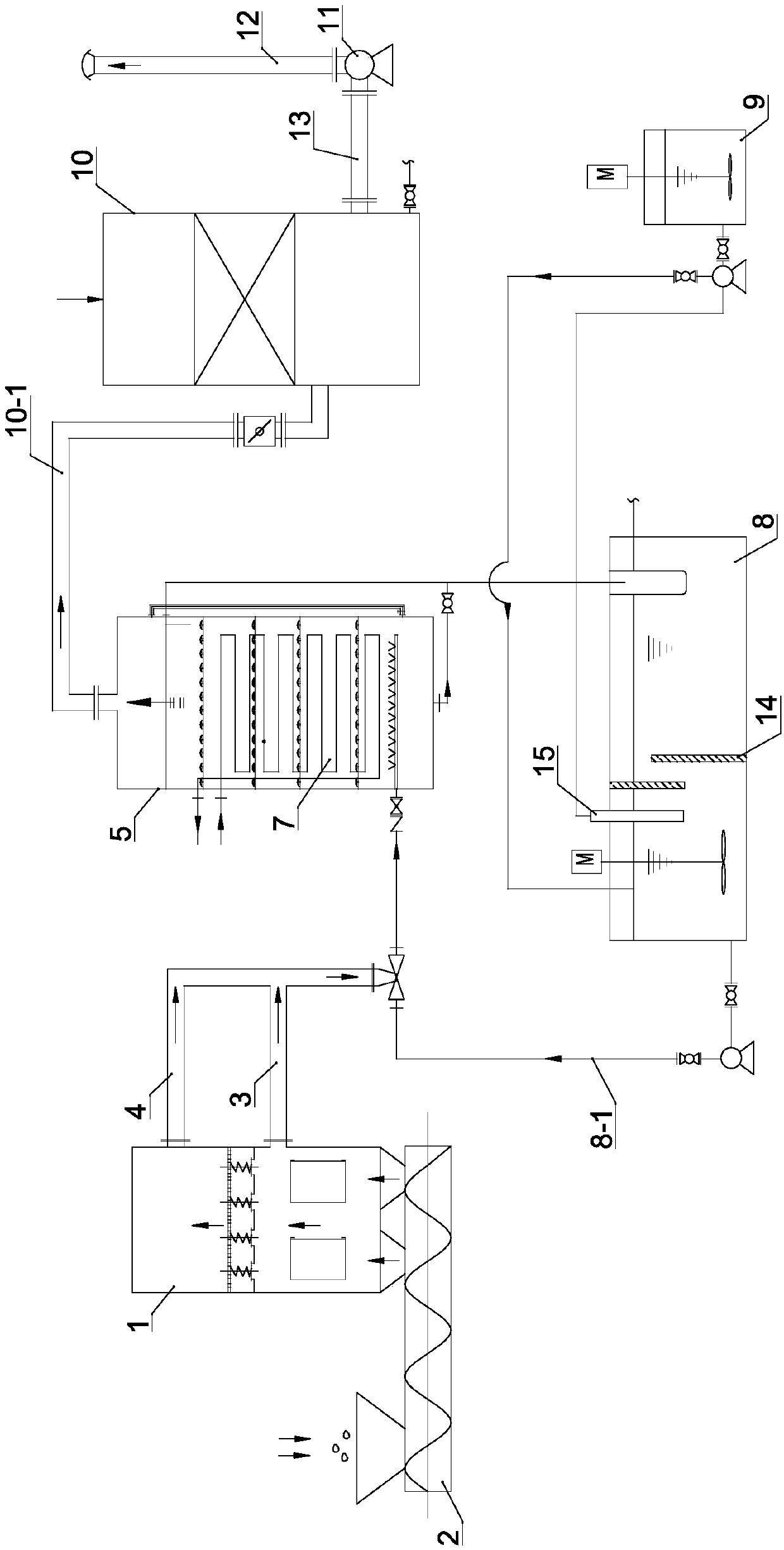

[0046] see figure 1 , a rubber slag waste gas treatment system of the present invention includes a gas collection module, a condensation pretreatment module for condensing and absorbing pretreatment of the collected waste gas, and a waste gas treatment for biological absorption treatment of the condensed and pretreated waste gas module.

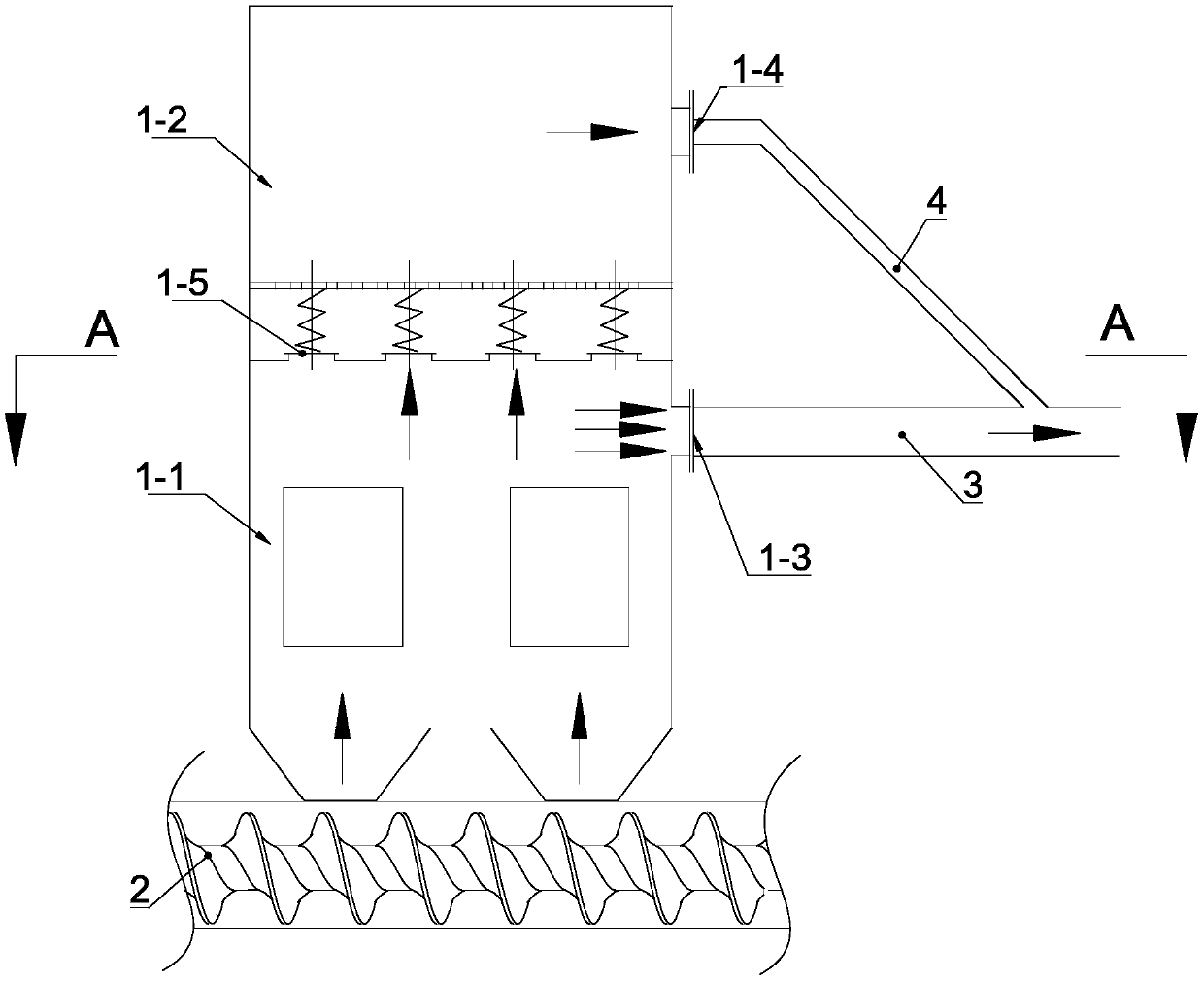

[0047] see figure 1 with 2 , the gas collection module includes an explosion relief gas collection hood 1, which is arranged above the exhaust port of the granulator 2, and includes a normal gas collection part 1-1 and a negative pressure explosion relief part 1- 2. The internal space of the normal gas collection part 1-1 is a gas collection and exhaust area, and the internal space of the negative pressure explosion relief part 1-2 is a negative pressure explosion relief area; the cover of the gas collection and exhaust area The wall is provided with a gas collection hood exhaust port 1-3, and the gas collection hood exhaust port 1-3 is co...

Embodiment 2

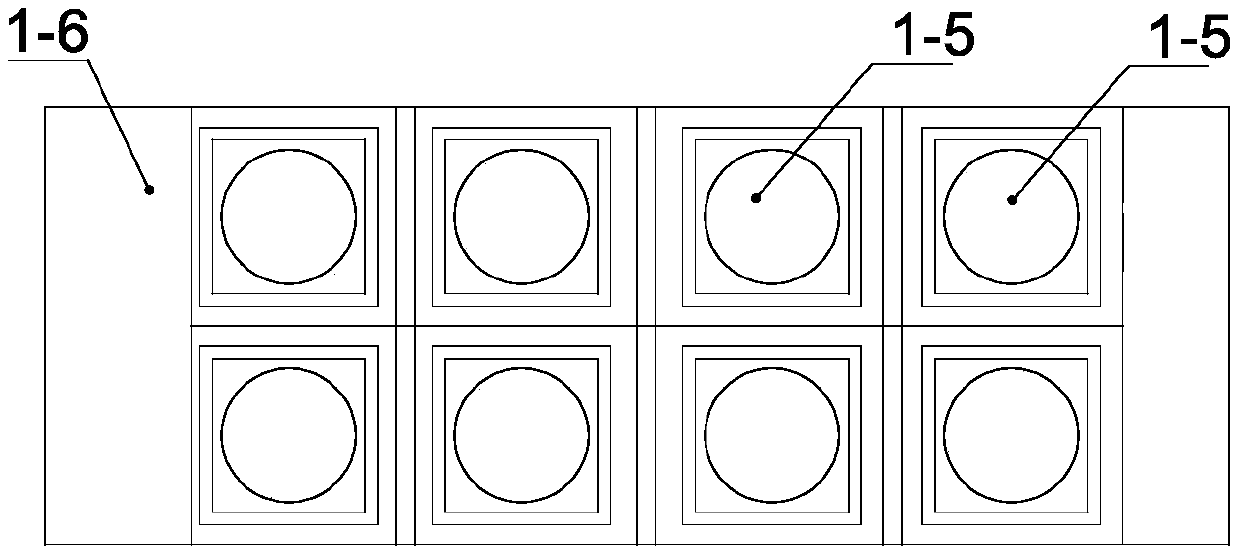

[0061] see Image 6 , The difference between this embodiment and Embodiment 1 is that the gas-gathering exhaust area and the negative pressure explosion relief area are separated by a partition plate 1-6, and the partition plate 1-6 is vertically arranged, divided into The area on one side of the partition 1-6 is the gas collection and exhaust area, and the area on the other side of the partition 1-6 is the negative pressure explosion relief area, and the explosion relief valve 1-5 is set on the partition 1-6 superior. When the explosion relief valve 1-5 is in the explosion relief state, the exhaust gas enters the negative pressure explosion relief area through the horizontal movement of the explosion relief valve 1-5, and then enters the first gas transmission main pipe 3 through the gas transmission branch pipe 4, thereby Realize exhaust gas venting task.

[0062] Refer to Embodiment 1 for implementation of other implementation modes other than the above in this embodiment...

Embodiment 3

[0064] see Figure 7 , The difference between this embodiment and Embodiment 1 is that the gas collection and exhaust area and the negative pressure explosion relief area are arranged in independent covers, and the corresponding covers of the gas collection and exhaust area and the negative pressure explosion relief area The bodies are connected through a large-diameter pipeline 1-7, and the explosion relief valve 1-5 is arranged in the large-diameter pipeline 1-7. When the explosion relief valve 1-5 is in the explosion relief state, the exhaust gas enters the cover corresponding to the negative pressure explosion relief area through the large-diameter pipeline 1-7, and then enters the first gas transmission main pipe 3 through the gas transmission branch pipe 4 , so as to realize the task of venting the exhaust gas.

[0065] Refer to Embodiment 1 for implementation of other implementation modes other than the above in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com