Spherical titanium powder and preparation method thereof as well as 3D printing product

A technology of spherical titanium powder and hydrogenation dehydrogenation titanium powder is applied in the direction of additive processing, which can solve the problems of high cost and complicated process, and achieve the effects of reducing production cost, simple production process and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of spherical titanium powder, specifically comprising the following steps:

[0026] S1. Hydrogenating the titanium sponge to obtain a titanium hydride; wherein, the titanium sponge is grade 1 titanium sponge, the hydrogenation treatment temperature is above 350° C., and the hydrogenation time is 10 hours;

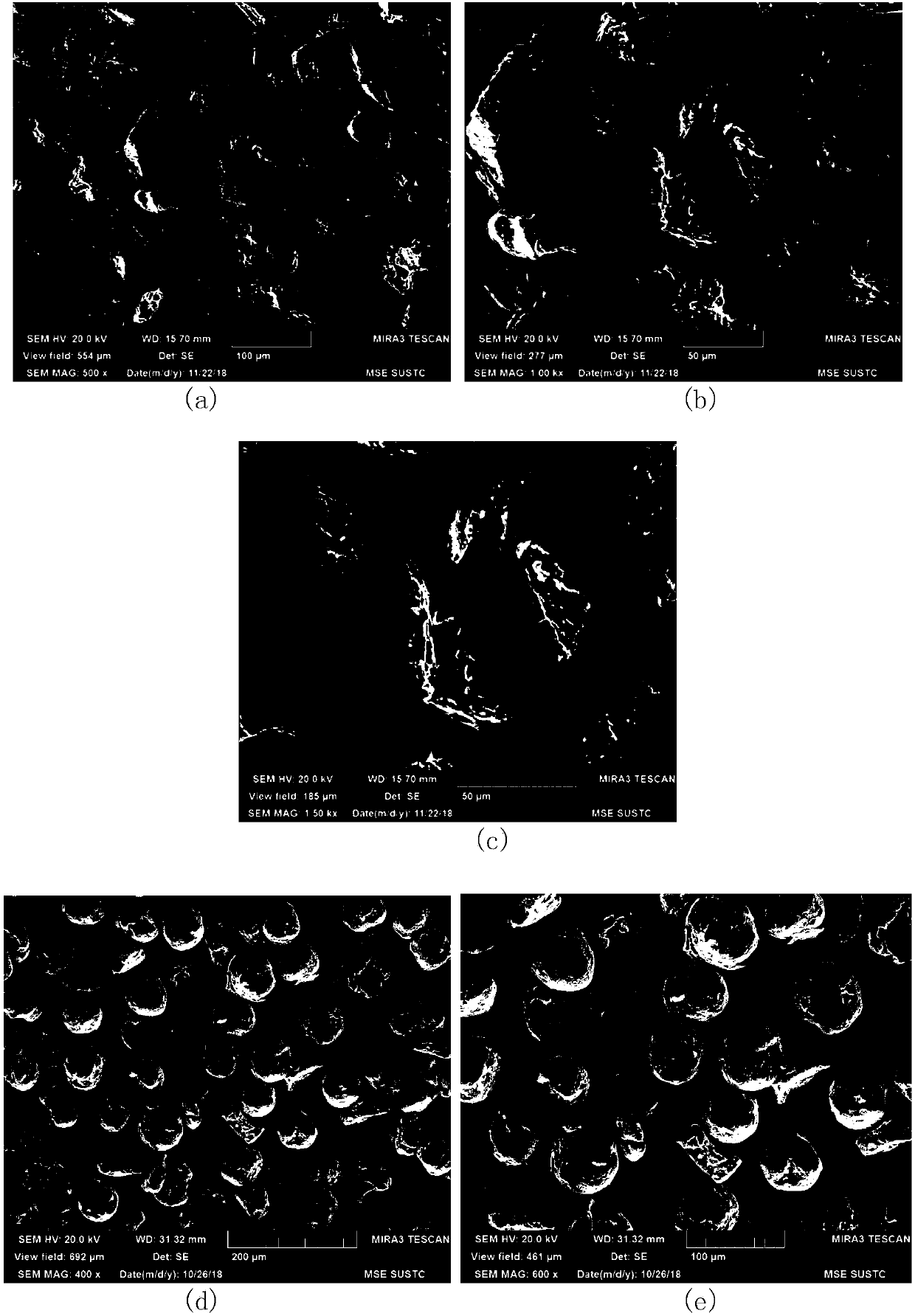

[0027] S2. Mechanically crushing the titanium hydride obtained in step S1 under a protective atmosphere of Ar gas to obtain titanium hydride powder;

[0028] S3. Dehydrogenating the titanium hydride powder obtained in step S2 at a temperature above 500° C. under vacuum conditions to obtain hydrogenated dehydrogenation titanium powder;

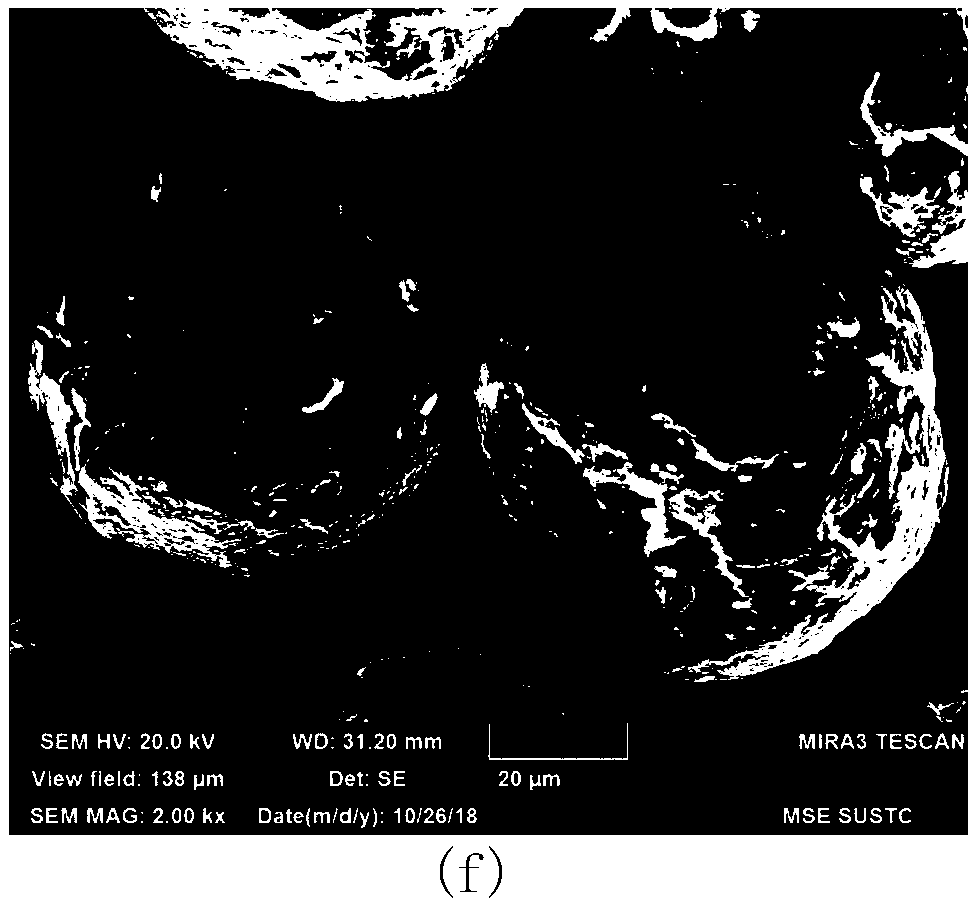

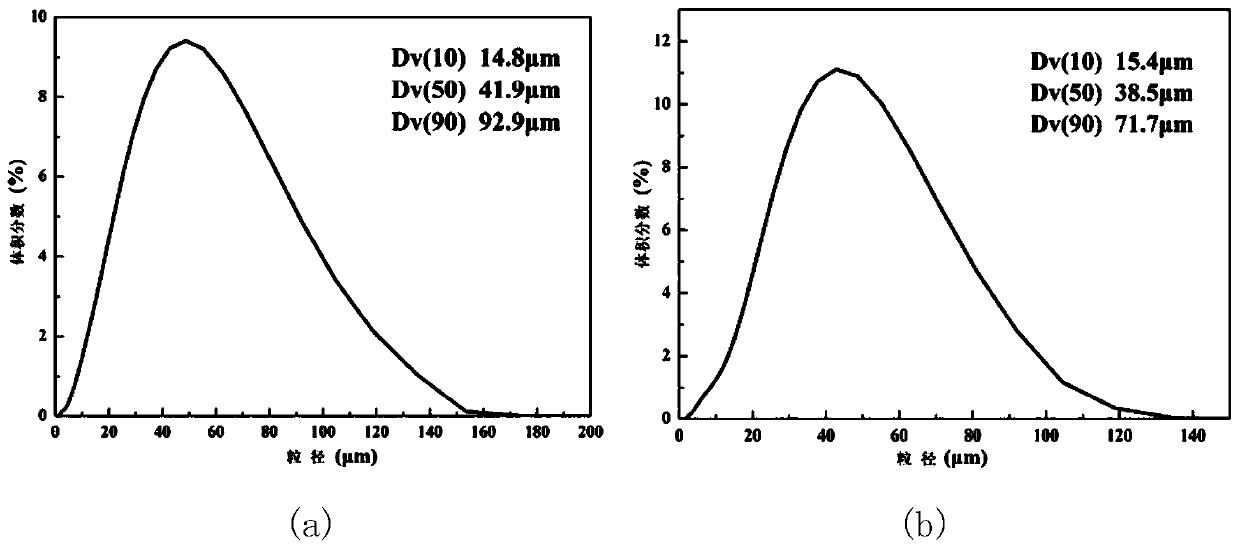

[0029] S4. Put the hydrogenated dehydrogenated titanium powder and agate balls obtained in step S3 into the ball mill modification equipment according to the ball-to-material ratio of 5:1, and add ethanol to submerge the hydrogenated dehydrogenated titanium powder and agate balls, and then introduce argon gas , c...

Embodiment 2

[0031] A preparation method of spherical titanium powder, specifically comprising the following steps:

[0032] S1. Hydrogenating the titanium sponge to obtain a titanium hydride; wherein, the titanium sponge is grade 1 titanium sponge, the hydrogenation treatment temperature is above 350° C., and the hydrogenation time is 10 hours;

[0033] S2. Mechanically crushing the titanium hydride obtained in step S1 under a protective atmosphere of Ar gas to obtain titanium hydride powder;

[0034] S3. Dehydrogenating the titanium hydride powder obtained in step S2 at a temperature above 500° C. under vacuum conditions to obtain hydrogenated dehydrogenation titanium powder;

[0035] S4, put the hydrogenated dehydrogenation titanium powder and agate balls obtained in step S3 into the ball mill modification equipment according to the ball-to-material ratio of 4:1, and add ethanol to cover the hydrogenated dehydrogenation titanium powder and agate balls, and then pass into argon air for ...

Embodiment 3

[0037] A preparation method of spherical titanium powder, specifically comprising the following steps:

[0038] S1. Hydrogenating the titanium sponge to obtain a titanium hydride; wherein the titanium sponge is grade 1 titanium sponge, the hydrogenation treatment temperature is above 350° C., and the hydrogenation time is 10 hours.

[0039] S2. Mechanically crushing the titanium hydride obtained in step S1 under a protective atmosphere of Ar gas to obtain titanium hydride powder;

[0040] S3. Dehydrogenating the titanium hydride powder obtained in step S2 at a temperature above 500° C. under vacuum conditions to obtain hydrogenated dehydrogenation titanium powder;

[0041] S4. Put the hydrogenated dehydrogenation titanium powder and agate balls obtained in step S3 into the ball mill modification equipment according to the ball-to-material ratio of 3:1, and add ethanol to submerge the hydrogenated dehydrogenation titanium powder and agate balls, and then pass in argon air for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com