Super-hydrophobic coating and preparation method and application thereof

A super-hydrophobic coating and coating technology, applied in anti-fouling/underwater coatings, rosin coatings, epoxy resin coatings, etc., can solve the problems of negative impact on the marine environment, long half-life, etc., achieve good use value, reduce adhesion, and hydrophobicity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The preparation method of silica airgel powder, comprises the following steps:

[0074] (1) Prepare a mixed solution of silicon source and solvent

[0075] Take sodium silicate with a modulus of 3.0 and put it into the reactor, add deionized water 6 times the mass of sodium silicate to dilute, stir the reactor at a speed of 300 rpm for 35 minutes, and filter through a 200-mesh sieve to obtain silicon Sodium acid solution;

[0076] (2) Sol

[0077] Take nitric acid, add water, and dilute the concentration to 20 mol / L, add aluminum nitrate and yttrium nitrate to the nitric acid, mix well, and add it to the silicon obtained in step (1) by submerged injection (simultaneous injection of multiple metering pumps) Sodium silicate solution; the whole feeding time is controlled at 20 minutes, the stirring speed is 325 rpm, the pH value of the sodium silicate solution is controlled to be 2.0, and the sol is obtained; the aluminum nitrate and yttrium nitrate are calculated as oxi...

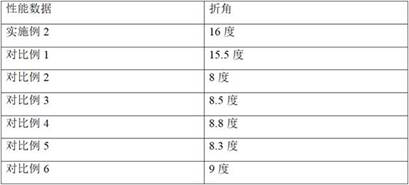

Embodiment 2

[0090] The raw materials of the adhesive, calculated in parts by weight, include:

[0091] 25 parts of distilled water;

[0092] 15 parts of silica sol;

[0093] 3 parts of perfluorooctyltrimethoxysilane;

[0094] 9 parts of magnesium hydroxide;

[0095] 3 parts of polyvinyl alcohol;

[0096] Polyurethane particles 5 parts.

[0097] The solid content of the silica sol is 30%.

[0098] The preparation method of silica sol is, comprises the following steps:

[0099] (1) Prepare a mixed solution of silicon source and solvent

[0100] Put sodium silicate with a modulus of 3.5 into the reaction kettle, add deionized water twice the mass of sodium silicate to dilute, stir the reaction kettle at a speed of 100 rpm for 30 minutes, and filter through a 200-mesh sieve to obtain silicon Sodium acid solution;

[0101] (2) Sol

[0102] Take sulfuric acid, adjust it to 10 mol / L with deionized water, add zirconium sulfate and cerium sulfate to the sulfuric acid, mix well, and add it...

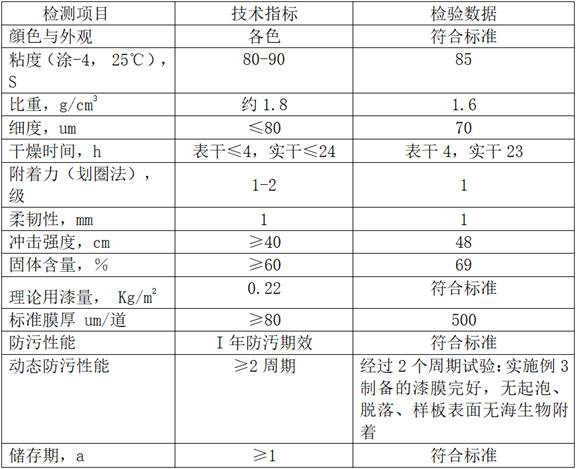

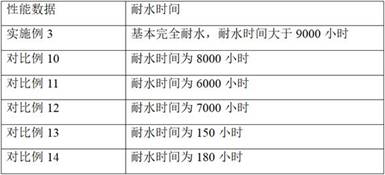

Embodiment 3

[0123] A kind of superhydrophobic coating, described superhydrophobic coating is the oily coating that contains antifouling microsphere

[0124] The formula of described oil paint is as:

[0125] Acrylic resin (NeoCryl B-810): 25 parts by weight;

[0126] E-44 epoxy resin: 6 parts by weight;

[0127] Rosin: 20 parts by weight;

[0128] 2 parts by weight of alumina airgel;

[0129] Antifouling microspheres: 4 parts by weight;

[0130] Pigments and fillers: 1 part by weight of talcum powder, 6 parts by weight of calcium phosphite, and 2 parts by weight of iron red;

[0131] Mixed solvent: 14 parts by weight of xylene, 6 parts by weight of ethyl acetate;

[0132] Kaolin: 4 parts by weight.

[0133] The antifouling microspheres are calculated in parts by weight, including

[0134] 30 parts of silicon airgel powder; (using the silicon airgel powder prepared in Example 1)

[0135] Adhesive 15 parts. (Adopt the adhesive prepared in Example 2)

[0136] The preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com