Laser tig hybrid welding process for improving undercutting of titanium and titanium alloy thin plates

A welding process, titanium alloy technology, applied in the field of laser TIG hybrid welding welding process, can solve the problems of slow welding speed, low welding efficiency, limited effect, etc., to solve the problem of undercut, ensure welding quality, and improve the effect of welding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The following takes the welding of a 0.9mm thick pure titanium TA2 thin plate as an example to describe in detail.

[0029] According to the above process flow, the laser TIG hybrid welding process is adopted, the equipment is IPG YLS-10000 multi-mode fiber laser and KUKA KRC2 welding robot, the welding power source is Xinwei MPT-500D, the diameter of the tungsten rod is 3.2mm, and the purity of the shielding gas is 99.9%. Argon gas, the gas flow rate is 18L / min.

[0030] 1. Preparation before welding

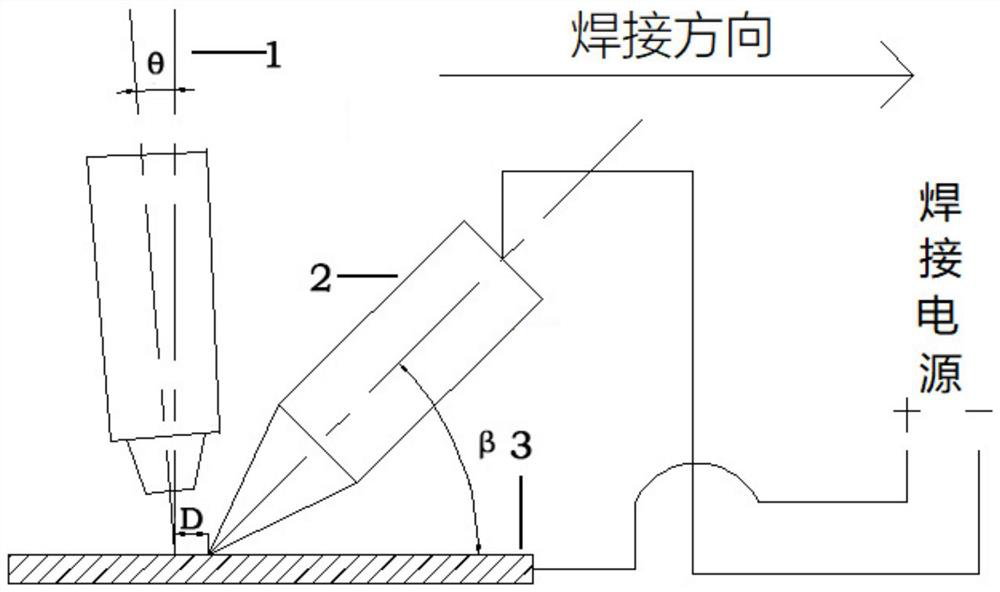

[0031] Adjust the welding torch angle and electrode spacing according to actual welding needs; in this example, the inclination angle of laser head 1 is θ=5°, the inclination angle of TIG welding torch 2 is β=45°, and the distance between heat sources is D=5mm.

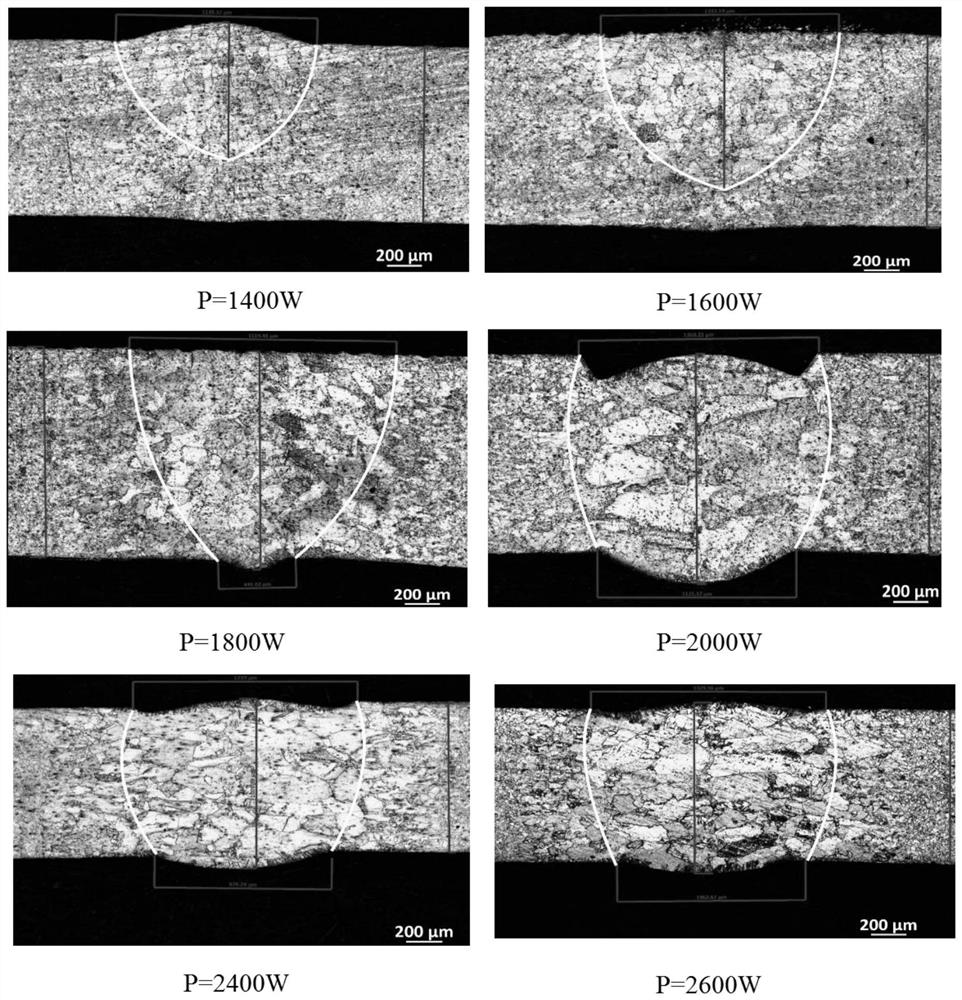

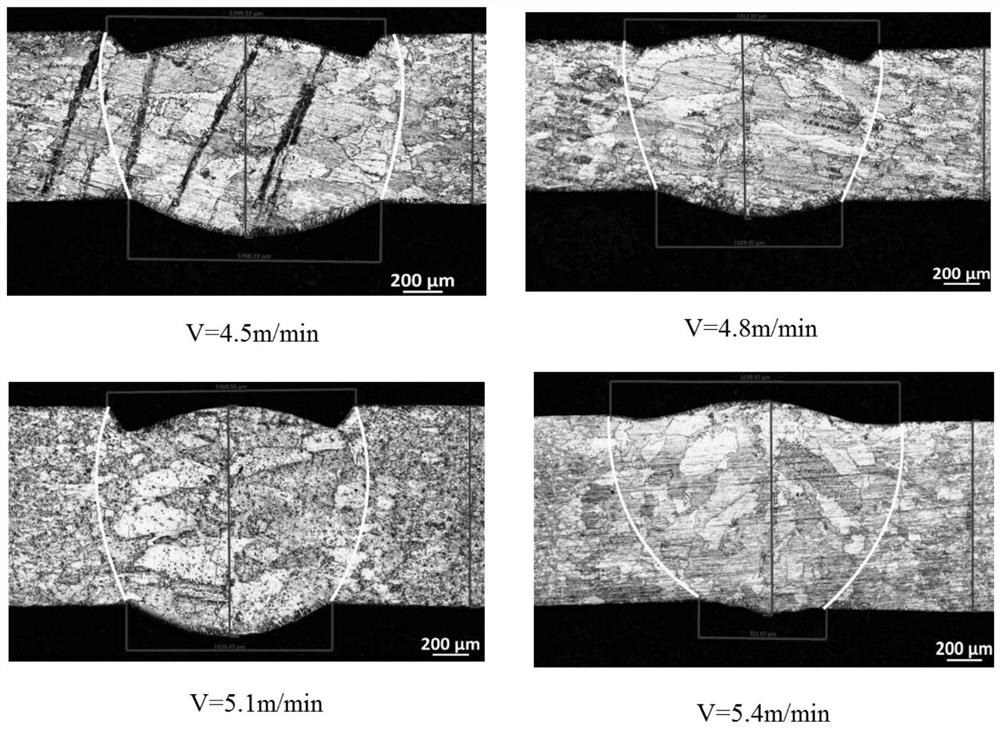

[0032] 2. Debug welding parameters

[0033] Set the laser parameters, the laser power is 2200W, the defocus is 25mm, the vertical distance between the laser head 1 and the workpiece 3 is 310mm, the welding spe...

Embodiment 2

[0046] Compared with Example 1, most of them are the same, except that in this example, the welding process parameters are controlled as:

[0047] The argon gas flow rate of TIG torch 1 is 15 L / min, and the argon gas flow rate of the back protection is 15 L / min. The welding current is 67.5A, the distance between the tip of the electrode and the workpiece 3 is about 2-3mm; the laser power is 1400W, the defocus is 25mm, the vertical distance between the laser head 1 and the workpiece 3 is 310mm, the welding speed is 4.8m / min, and the distance between the heat sources is D = 1 mm, the inclination angle θ of the laser head 1 = 5°, and the inclination angle β of the TIG welding torch 2 = 45°.

Embodiment 3

[0049] Compared with Example 1, most of them are the same, except that in this example, the welding process parameters are controlled as:

[0050] The argon gas flow of TIG welding torch 1 is 18L / min, and the argon gas flow of back protection is 18L / min. The welding current is 65A, the distance between the tip of the electrode and the workpiece 3 is about 2-3mm; the laser power is 1800W, the defocus is 25mm, the vertical distance between the laser head 1 and the workpiece 3 is 310mm, the welding speed is 6m / min, and the heat source distance is D= 9mm, the inclination angle θ of the laser head 1 = 5°, and the inclination angle β of the TIG welding torch 2 = 45°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com