g-C3N4 photocatalyst with marginal nitrogen vacancy and preparation method thereof

A photocatalyst, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, nitrogen compounds, etc., can solve the problems of large π bond destruction, destruction of conjugated structure, lack of, etc., to improve catalytic performance, Mild reaction conditions and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A marginal nitrogen vacancy g-C 3 N 4 The preparation method of photocatalyst comprises the steps:

[0039] (1) Put 5g of melamine powder into the porcelain boat, then put the porcelain boat into the quartz tube;

[0040] (2) Put the quartz tube into the tube furnace, and then in 100sccmAr / CCl 4 In the atmosphere, react at 550°C for 4h;

[0041] (3) Stir and wash the obtained product in deionized water for 30 minutes to remove impurities, and dry at 50° for 4 hours to obtain the marginal nitrogen vacancy g-C 3 N 4 .

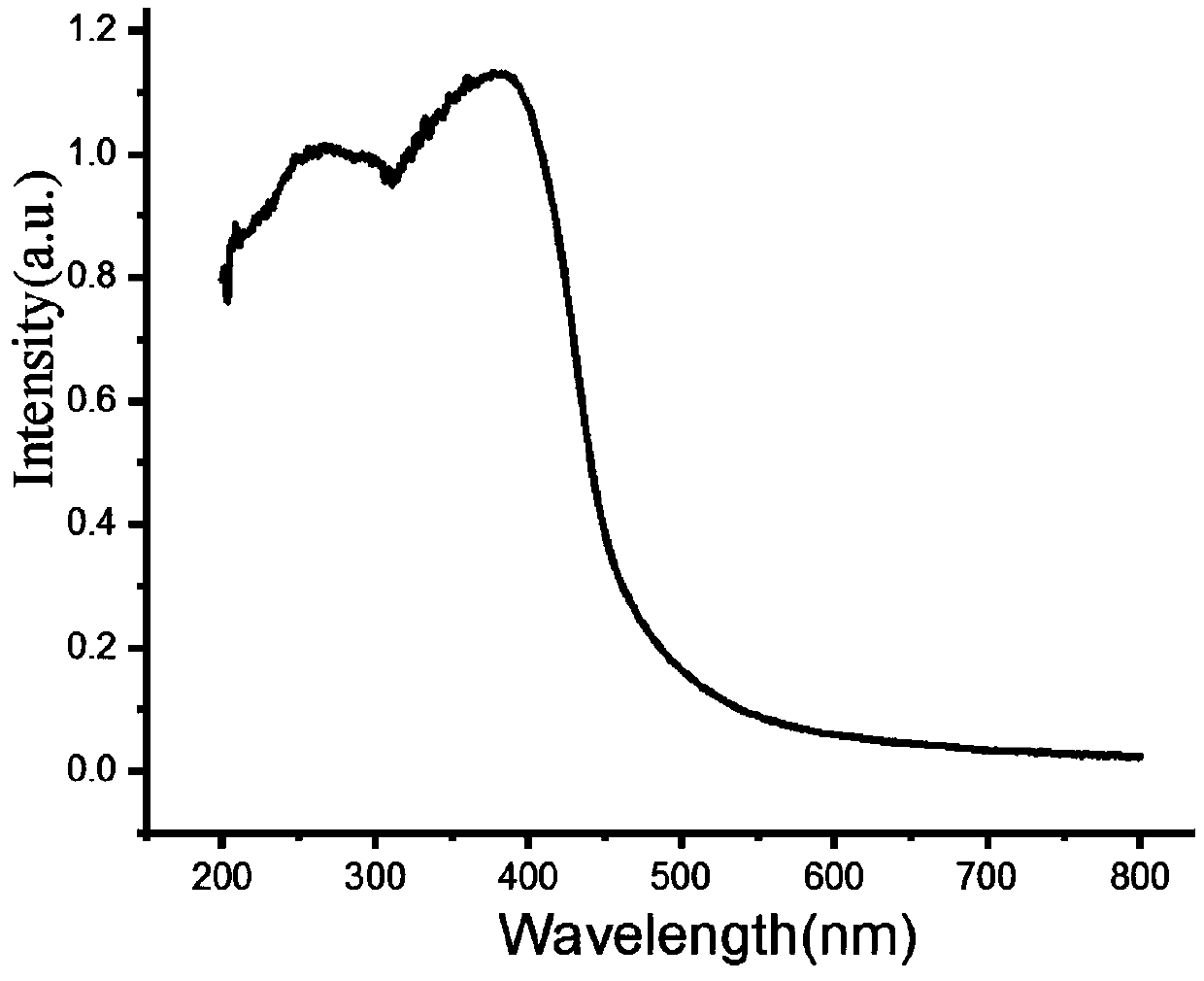

[0042] figure 1 g-C prepared for this example 3 N 4 It can be seen from the figure that the prepared product has strong visible light absorption (the absorption band edge extends to about 450nm), and has a slope-shaped tailing absorption at about 500nm, which is caused by defects. The resulting impurity energy bands indicate the successful preparation of defects.

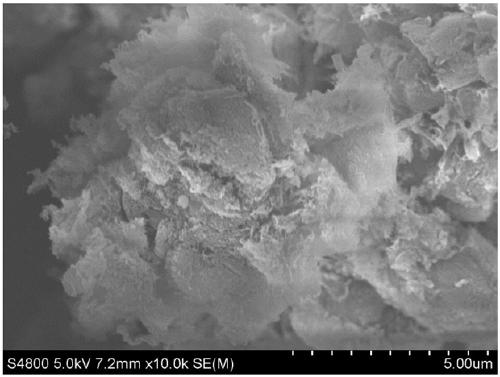

[0043] figure 2 g-C prepared for this example 3 N 4 From the SEM picture, it c...

Embodiment 2

[0049] a g-C 3 N 4 A marginal nitrogen vacancy and a preparation method thereof, comprising the steps of:

[0050] (1) Put 3g of melamine powder into the porcelain boat, and then put the porcelain boat into the quartz tube.

[0051] (2) The quartz tube is put into a tube furnace, and then heated at 150sccmAr / CCl 4 The reaction was carried out at 550°C for 4h.

[0052] (3) The obtained product was stirred and washed in deionized water for 60 minutes to remove impurities, and dried at 30° for 5 hours to obtain the marginal nitrogen vacancy g-C 3 N 4 .

Embodiment 3

[0054] a g-C 3 N 4 A marginal nitrogen vacancy and a preparation method thereof, comprising the steps of:

[0055] (1) Put 10g of melamine powder into the porcelain boat, and then put the porcelain boat into the quartz tube.

[0056] (2) The quartz tube is put into a tube furnace, and then heated at 50sccmAr / CCl 4 The reaction was carried out at 700°C for 1 h.

[0057] (3) Stir and wash the obtained product in deionized water for 2 hours to remove impurities, and dry it at 100° for 1 hour to obtain the marginal nitrogen vacancy g-C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com