Recycling treatment technology of high-concentration organic waste alkaline liquor

A waste lye recycling technology, applied in alkali metal chloride, oxidized water/sewage treatment, multi-stage water treatment, etc., can solve problems such as low calorific value, high equipment requirements, and large amount of waste liquid, and achieve The effect of reducing processing costs, realizing resource utilization, and reducing processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

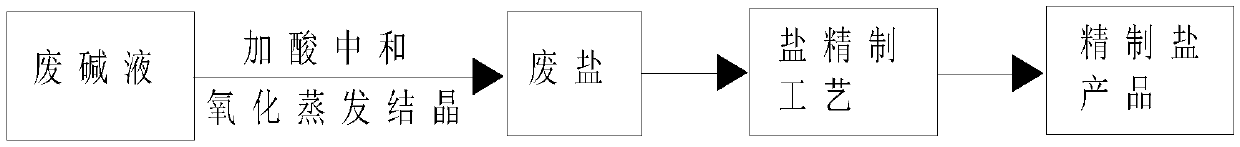

Method used

Image

Examples

Embodiment 1

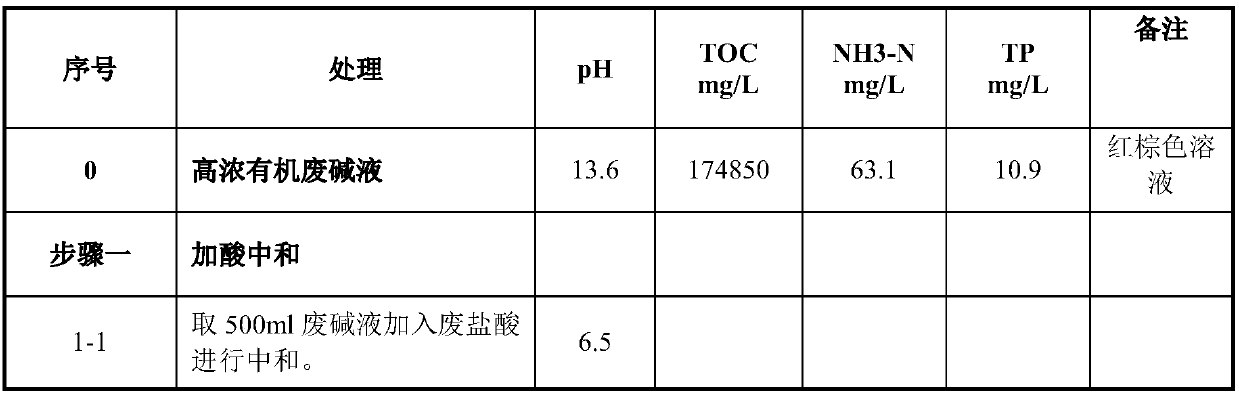

[0027] The high-concentration organic waste lye in this implementation example comes from a pesticide factory. It is a reddish-brown solution with peculiar smell, and the concentration of sodium hydroxide is 12%. This implementation case uses waste hydrochloric acid for neutralization. The waste hydrochloric acid comes from a pharmaceutical factory. The concentration of hydrochloric acid is 8%, the concentration of organic matter is high, TOC: 93780mg / L, and the solution is orange-yellow liquid.

[0028] Table 1 Details of experimental steps and experimental results

[0029]

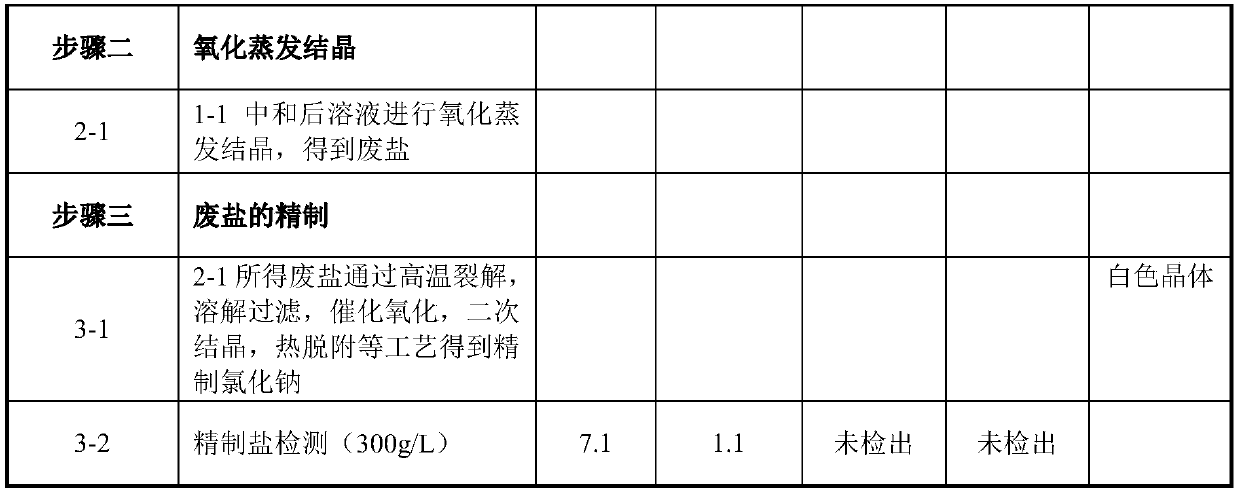

[0030]

[0031] It can be seen from the data in Table 1 that the content of organic matter in the waste lye and the waste acid used for neutralization is relatively high, the waste salt solution is obtained after neutralization, the waste salt is obtained after oxidation, evaporation and crystallization, and the waste salt is obtained after the refined salt process. Sodium chloride refined salt, fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com