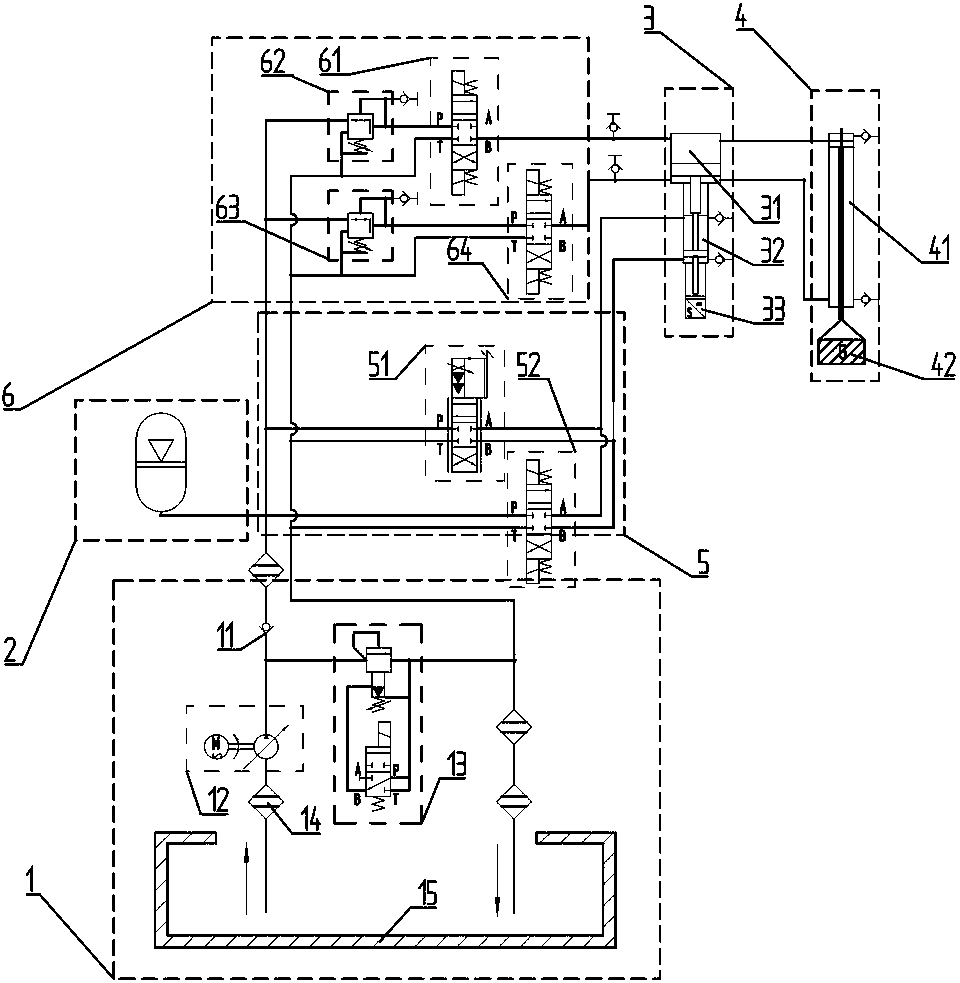

Feeding hydraulic system

A hydraulic system and hydraulic cylinder technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problem of difficulty in continuously releasing high-power drive energy, limited ability of hydraulic oil to store potential energy, and large flow of hydraulic oil, etc. Problems, to achieve the effect of reducing development and maintenance costs, large feed load, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The working process of this embodiment is as follows:

[0034] In the preparation stage, the hydraulic oil in the oil tank 15 is pressurized by the hydraulic pump 12 and sent to the high-pressure tank 2 through the check valve 11 to compress the nitrogen in the tank. The liquid level of the hydraulic oil in the tank rises, and the nitrogen is compressed to a predetermined value of 15MPa-30Mpa. Pressure; when the pressure is too high, the overflow valve 13 is opened to release the pressure, and the hydraulic pump 12 stops working.

[0035] During use, the high-pressure tank 2 forms a hydraulic circuit through the pipeline, the feeding and lifting pipeline valve assembly 5 and the servo control and proportional increasing hydraulic cylinder 3 . When the load 42 needs to be quickly sent to the flow field, the servo flow valve 51 in the feed and lift pipeline valve assembly 5 is opened, and the high-pressure hydraulic oil enters the servo-controlled and proportional speed-u...

Embodiment 2

[0040] The implementation mode of this embodiment is basically the same as that of Embodiment 1, the main difference is:

[0041] During the factory commissioning of the equipment and the function recovery commissioning after the equipment maintenance, the high-pressure tank 2, the equipment commissioning pipeline valve assembly 6, the servo control and proportional increase hydraulic cylinder 3 and the fast execution hydraulic cylinder 41 form a commissioning loop. Its function is to remove the air in the hydraulic pipeline and hydraulic cylinder, and to determine the initial position of the hydraulic cylinder piston. The device initialization is realized through the upper layer control software, which plays an important role in the factory commissioning of the device and the function recovery after the overhaul of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com