Catalyst for preparing isoolefin by cracking tertiary alkyl ether, preparation method for catalyst and application of catalyst

A tertiary alkyl ether and catalyst technology, applied in the field of catalysts, can solve the problems of low feed load, decreased reaction activity, increased reaction energy consumption, etc., and achieves the effects of large feed load, high stability and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

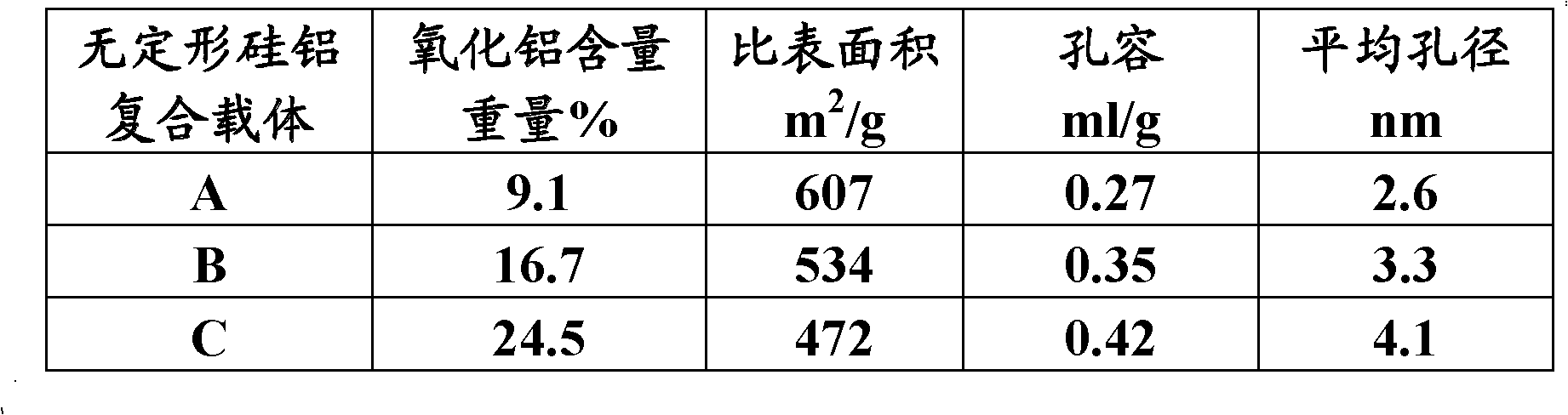

[0034] Preparation of Amorphous Si-Al Composite Support

[0035] Amorphous silicon-aluminum composite carrier A

[0036] Take 150g of silica sol solution and pour it into a beaker, add 5% hydrochloric acid solution dropwise at 50°C until the pH value is 4, age for 2 hours, take 120ml of an aqueous solution containing 29.9g of aluminum sulfate, pour it into a beaker, and stir at 50°C , then adjust the pH value to 9 with ammonia water, age at room temperature for 4 hours, filter and wash with water, dry at 120°C for 6 hours, then grind into powder, add 8% by weight of cellulose based on the obtained powder and mix well, add A small amount of dilute nitric acid aqueous solution was kneaded, extruded into strips of Φ3mm, dried at 120°C for 5 hours, and then calcined at 500°C for 5 hours to obtain amorphous silicon-aluminum composite carrier A.

[0037] Amorphous silicon aluminum composite carrier B

[0038] Take 150g of silica sol solution and pour it into a beaker, add 5%...

Embodiment 2

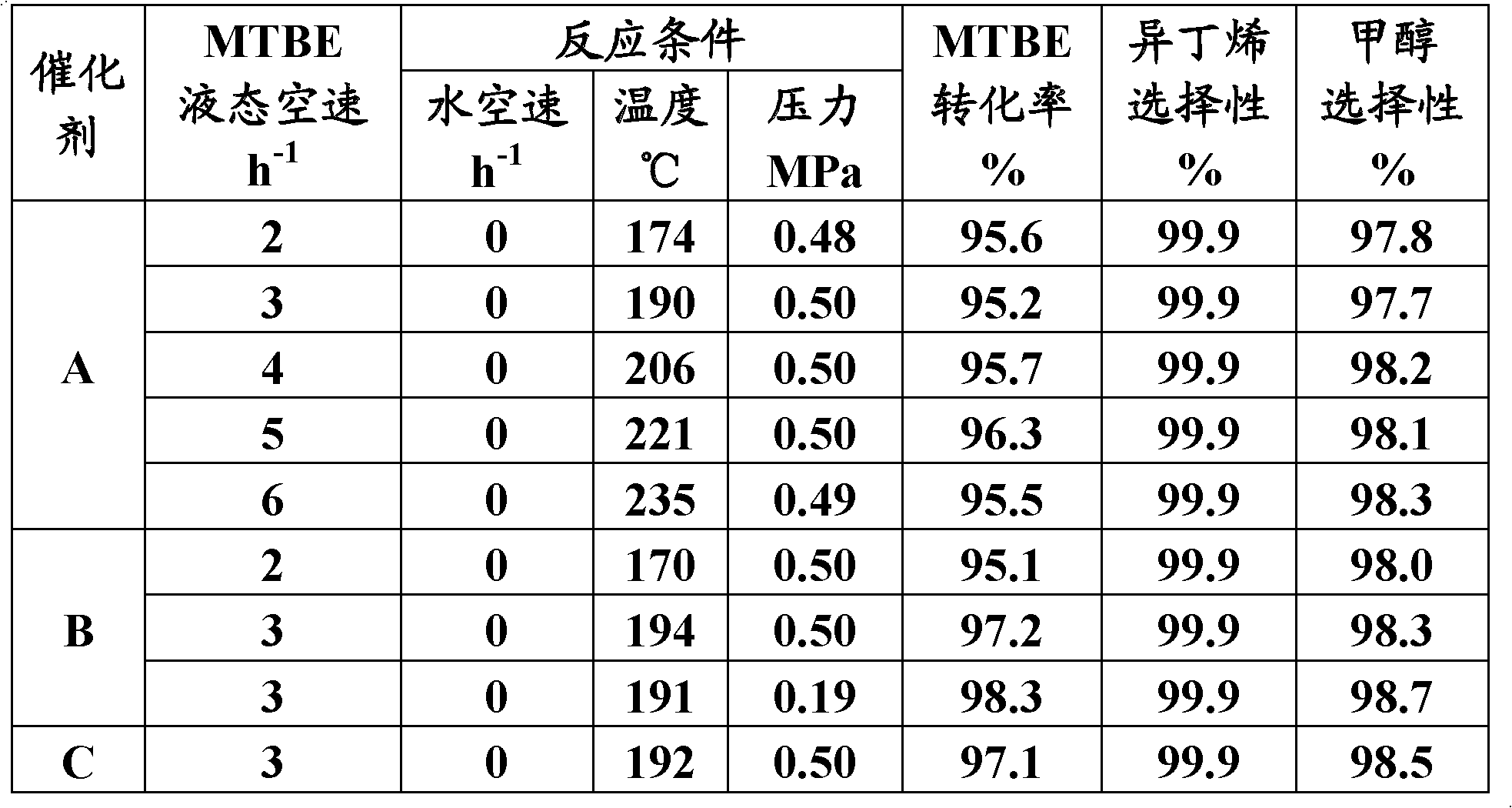

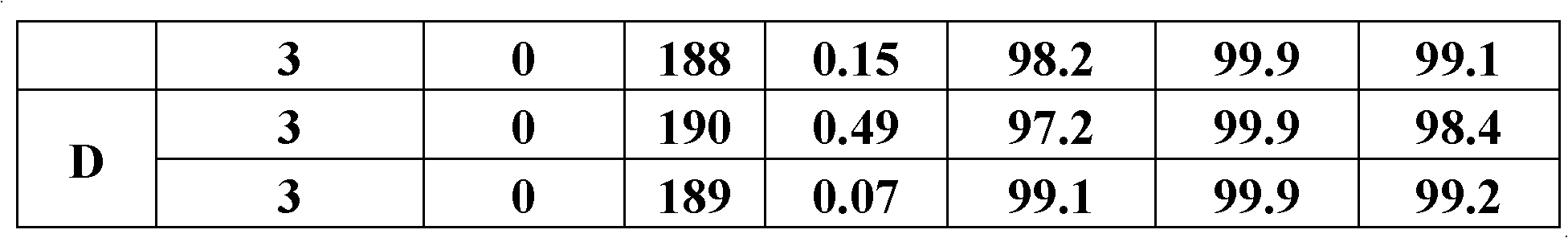

[0045] Weigh 30.1g of ammonium sulfate and dissolve it in 100ml of deionized water, impregnate 56g of amorphous silicon-aluminum composite carrier A in the solution for 2 hours at room temperature, filter, dry at 120°C for 3 hours, and dry at 500°C in an air atmosphere ℃ for 4 hours to obtain catalyst A. The sulfur oxide content of catalyst A was measured by chemical analysis method as SO 4 2- 8.1% by weight based on the weight of the catalyst.

Embodiment 3

[0047] Weigh 45.2g of ammonium sulfate and dissolve it in 100ml of deionized water, immerse 56g of amorphous silicon-aluminum composite carrier A in the solution for 3 hours at room temperature, filter, dry at 110°C for 4 hours, and dry at 600°C in an air atmosphere. ℃ for 3 hours to obtain catalyst B. The sulfur oxide content of catalyst B was measured by chemical analysis method as SO 4 2- 11.7% by weight based on the weight of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com