Multi-loop direct-current submerged arc furnace without bottom electrode

A submerged arc furnace, multi-circuit technology, applied in the field of submerged arc furnace, can solve the problems of high electrode consumption, short service life of furnace bottom, increase the cost of submerged arc furnace, etc., and achieve the effect of improving efficiency, uniform charge temperature and strong energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

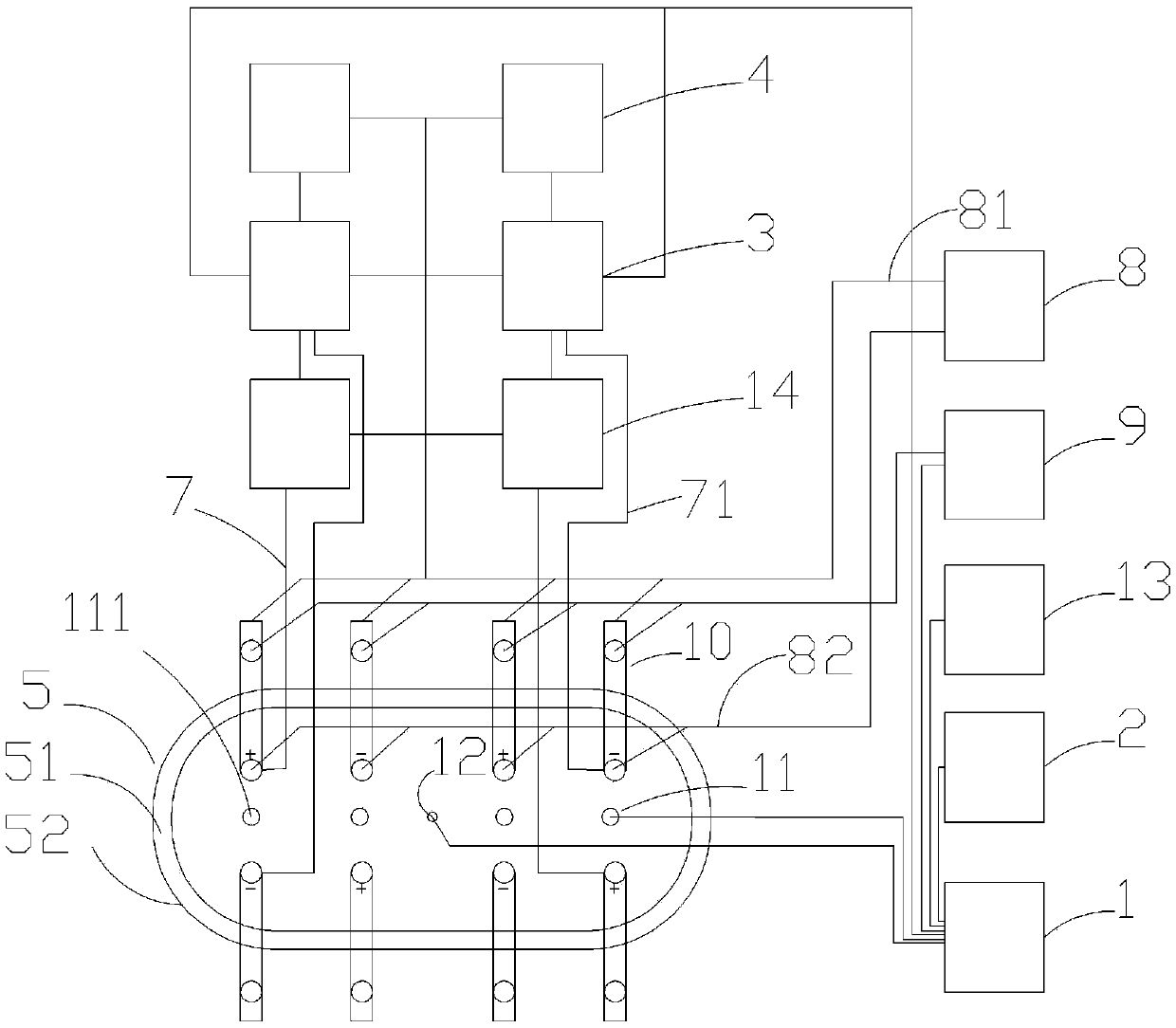

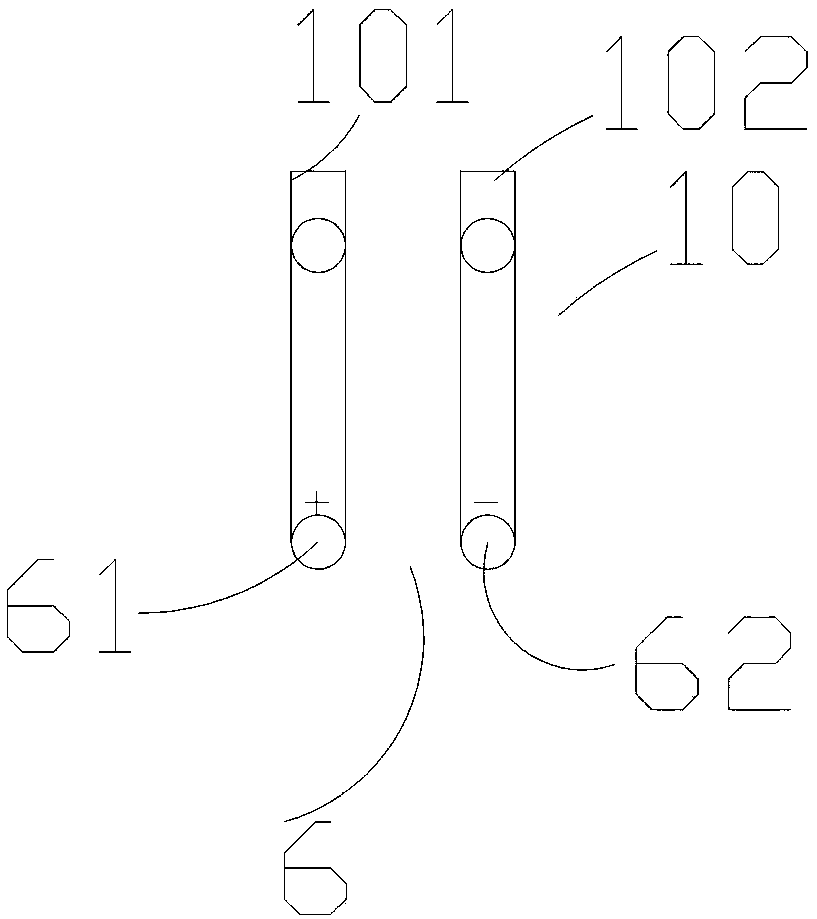

[0042] Such as Figure 1-3 As shown, a multi-circuit bottomless electrode DC submerged arc furnace includes:

[0043] The main control cabinet 1 is used to collect digital and analog quantities on site and automatically control the submerged arc furnace. The main control cabinet 1 is provided with a PLC for automatic control and an I / O connected to the PLC. O module relay terminal block;

[0044] The console 2 is connected to the main control cabinet 1, and the console 2 is provided with an opening and closing switch (not shown in the figure), an automatic start-stop button, an emergency stop button, an indicator light, and a switch for data recording and statistics. Archived computers (none are shown);

[0045] The rectifier 3 is connected to the main control cabinet 1 and can convert alternating current into direct current;

[0046]The transformer 4 is connected to the mains power transmission and the rectifier 3 and is capable of stepping down and isolating the high-volt...

Embodiment 2

[0075] In this embodiment, the reactor 14 is also connected between the rectifier 3 and the first short network 7, and the reactor 14 can suppress the current change rate and flat wave, and when the first short network on site When the grid 7 is close, the reactor 14 is required to suppress the rate of change of the current and make a flat wave. This embodiment only limits the reactor 14 , and everything else is the same as in Embodiment 1.

Embodiment 3

[0077] In this embodiment, the rectifier 3 adopts a 12-pulse rectification system, and by using N sets of DC power supplies to form N sets of circuits, 12*N pulse wave rectification can be realized. This embodiment is only limited to the rectifier 3 , other than that, it is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com