High-temperature pipeline wall thickness online monitoring device and method based on ultrasonic waveguide

A technology for monitoring devices and pipe walls, applied to measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as inability to measure continuously for a long time, immature technology, large volume and weight, etc., to solve the problem of liquid couplant failure, Good sound transmission effect, the effect of increasing the detection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

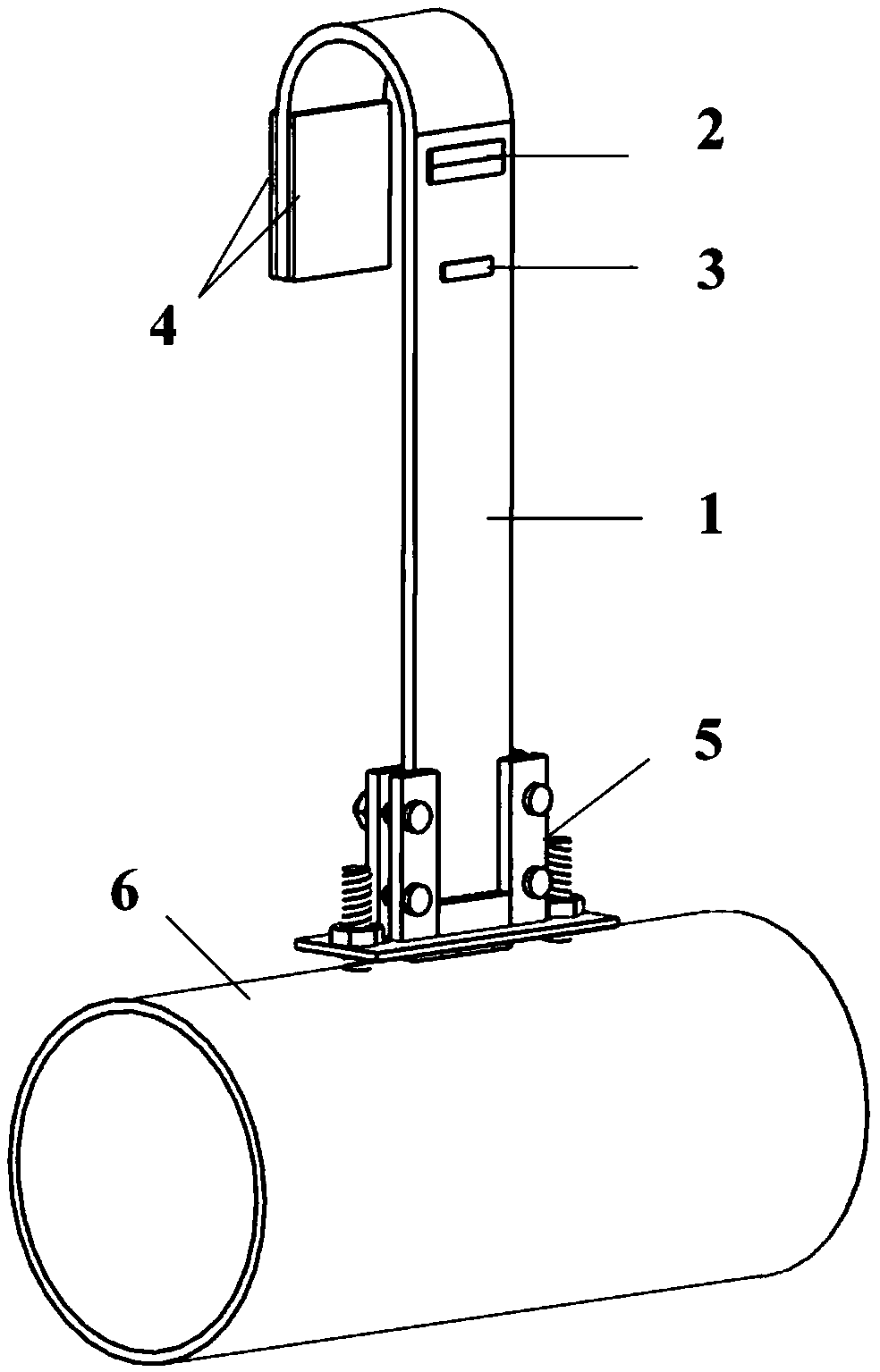

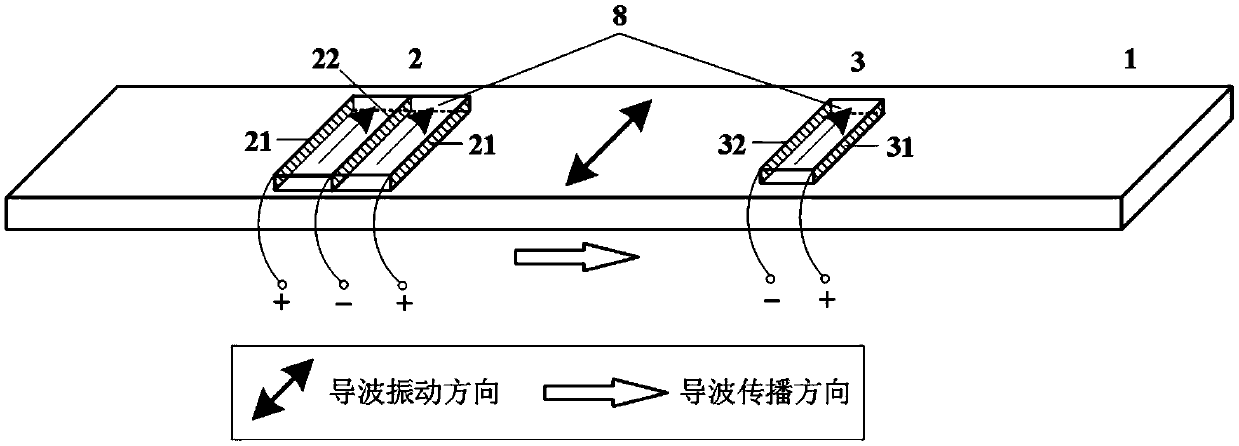

[0033] Such as figure 1 As shown, the ultrasonic waveguide-based online monitoring device for high-temperature pipeline wall thickness in this embodiment includes: a waveguide structure 1, a transmitting piezoelectric transducer 2, a receiving piezoelectric transducer 3, a waveguide connector 5, an acoustic absorption structure 4, An oscilloscope and a pulsed ultrasonic signal source; wherein, the waveguide structure 1 includes a sound absorbing end connected as one, a transition section and a cooling and heat insulating waveguide, the cooling and heat insulating waveguide is in the shape of a slab, and the top of the cooling and heat insulating waveguide is connected to the sound absorbing waveguide through the transition section The transition section is an arc-shaped bending waveguide. The sound absorption end, the transition section, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com