Mesoporous material-base antibacterial composite resin for dental department and preparation method thereof

A technology of mesoporous materials and composite resins, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of limited performance improvement of composite resins, uneven dispersion, low addition of antibacterial agents, etc., to improve the contact area The ability to combine with the interface, the preparation method is simple, and the effect of preventing material fracture and secondary caries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

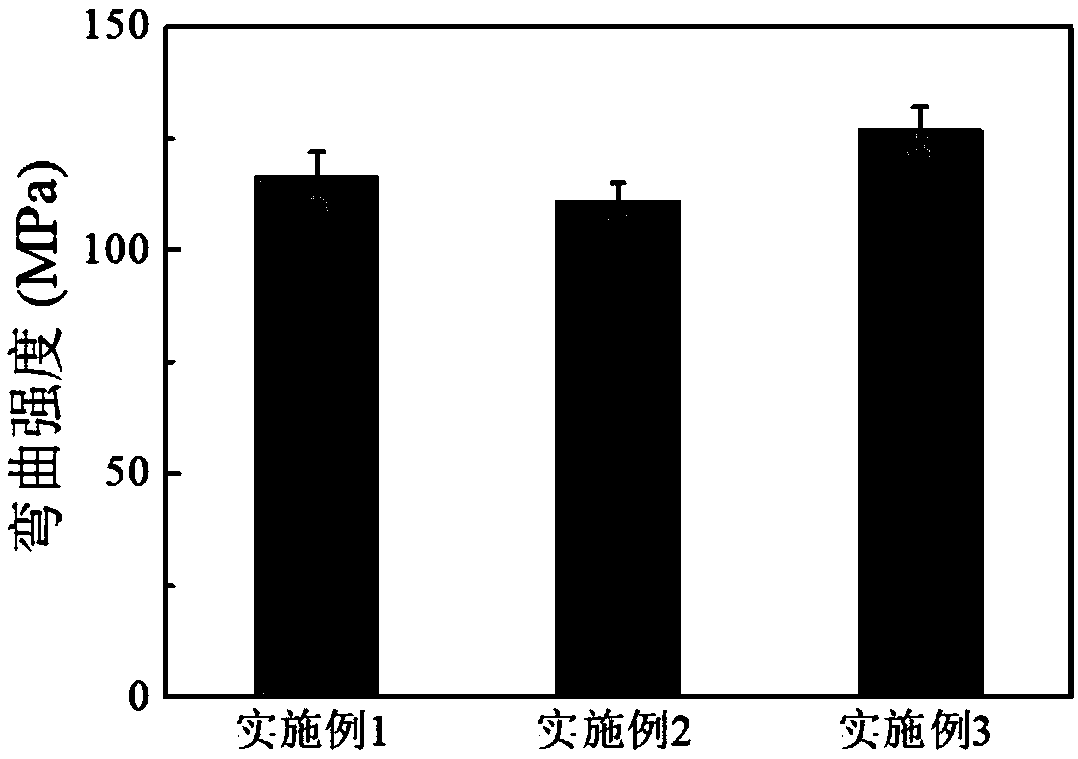

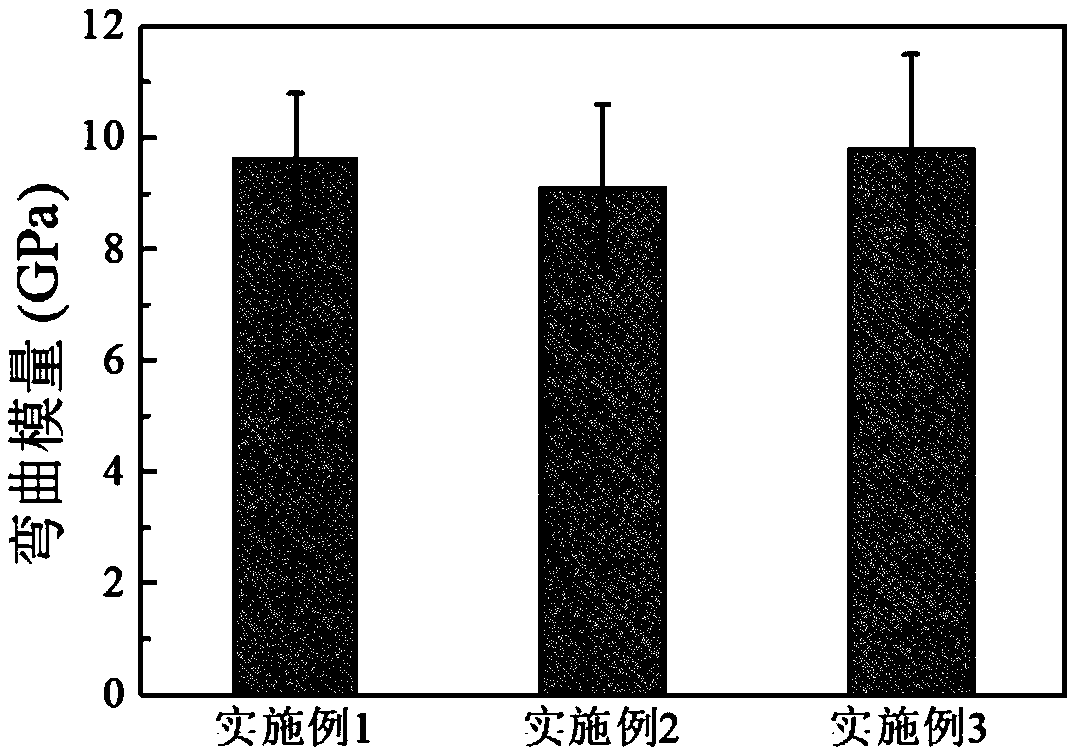

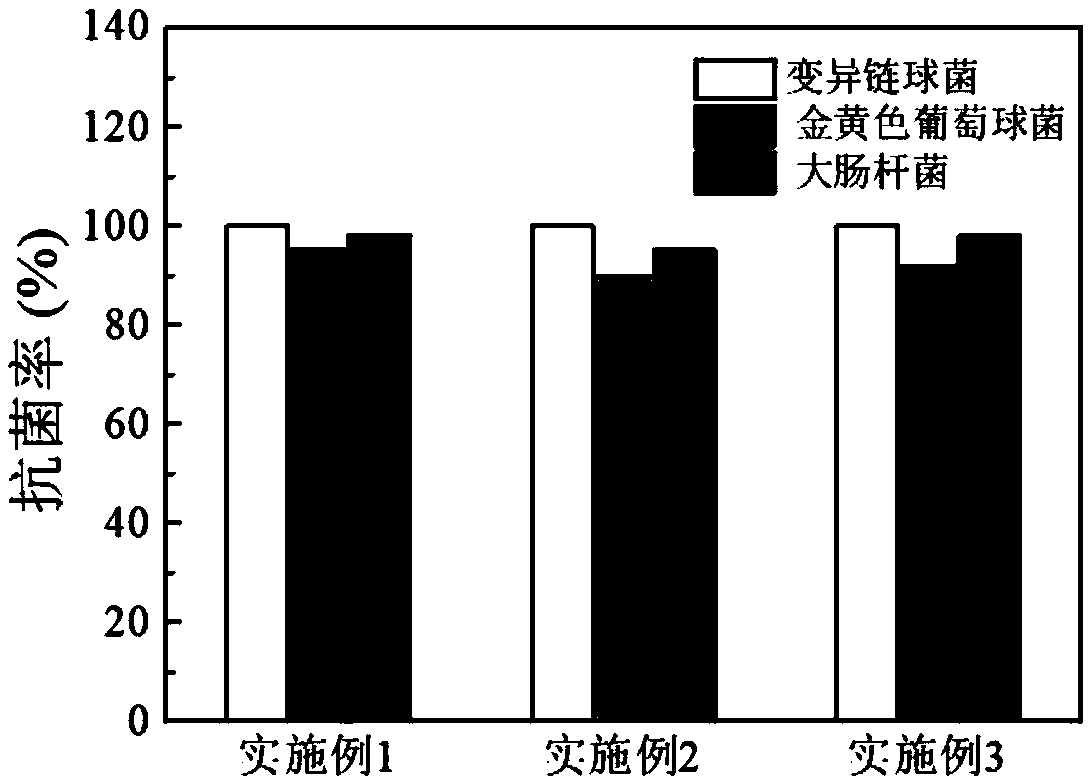

Embodiment 1

[0036] (1) Synthesis of Ag@mesoporous hydroxyapatite HAP

[0037] ① Use phosphoric acid to modify mesoporous HAP (average pore diameter: 28nm) to obtain mesoporous HAP with phosphate groups on the surface. The process parameters for phosphoric acid modified mesoporous HAP are: the mass ratio of phosphoric acid to mesoporous HAP with a mass fraction of 85% The ratio is 10:1, the reaction temperature is 60°C, and the reaction time is 40 minutes.

[0038] ② Add silver chloride to the water / ethanol system to configure the solution, wherein the mass ratio of silver chloride to water / ethanol is 10:90, and the mass ratio of water to alcohol is 1:2, and then the solution is added drop by drop at room temperature Add it to the above-mentioned mesoporous HAP solution with phosphate groups on the surface, and stir and react at 65° C. for 2 hours to obtain the Ag@mesoporous HAP sol precursor. Subsequently, the sol precursor was centrifuged and washed with water, and then dried in a vacuu...

Embodiment 2

[0046] (1) Ag@mesoporous Al 2 o 3 Synthesis

[0047] ①Modification of mesoporous Al by hydrochloric acid 2 o 3 (average pore size: 42nm) to obtain mesoporous Al with chloride ions on the surface 2 o 3 , using hydrochloric acid to modify mesoporous Al 2 o 3 The process parameters are: hydrochloric acid with a mass fraction of 37% and mesoporous Al 2 o 3 The mass ratio is 15:1, the reaction temperature is 65° C., and the reaction time is 45 minutes.

[0048] ② Add silver nitrate to the water / methanol system to configure the solution, wherein the mass ratio of silver nitrate to water / methanol is 12:88, and the mass ratio of water to alcohol is 1:1.5, then add the solution dropwise to Mesoporous Al with chloride ions on the surface 2 o 3 In the solution, the reaction was stirred at 75°C for 3h to obtain Ag@mesoporous Al 2 o 3 Sol precursor. Then the sol precursor was centrifuged and washed with water, and then dried in a vacuum oven at 110°C for 8 hours to obtain Ag@...

Embodiment 3

[0056] (1) Ag@mesoporous SiO 2 Synthesis

[0057] ①Using phosphoric acid to modify mesoporous SiO 2 (average pore size: 36nm) to obtain mesoporous SiO with phosphate on the surface 2 , using phosphoric acid to modify mesoporous SiO 2 The process parameters are: phosphoric acid with a mass fraction of 85% and mesoporous SiO 2 The mass ratio is 10:1, the reaction temperature is 60° C., and the reaction time is 45 minutes.

[0058] ② Add silver chloride to the water / ethanol system to prepare the solution, wherein the mass ratio of silver nitrate to water / ethanol is 20:80, and the mass ratio of water to ethanol is 1:1, then add the solution dropwise at room temperature to the above-mentioned mesoporous SiO with phosphate groups on the surface 2 solution, stirred and reacted at 85°C for 3h to obtain Ag@mesoporous SiO 2 Sol precursor. Then the sol precursor was centrifuged and washed with water, and then dried in a vacuum oven at 105 °C for 8 h to prepare Ag@mesoporous SiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com