Hydrocarbon producing equipment and method based on methyl alcohol normal-temperature feeding reaction

A methanol and feeding technology, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, biological raw materials, etc., can solve the problems of increasing equipment costs, low yield of refined oil, and large volume requirements of equipment, and saves energy. and equipment, the effect of vigorous molecular motion and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Adopting the hydrocarbon production method of the present invention, using methanol mixed with waste gasoline, waste diesel oil, liquefied gas, and heavy acetylene mixture as a raw material to prepare gasoline, comprises the following steps:

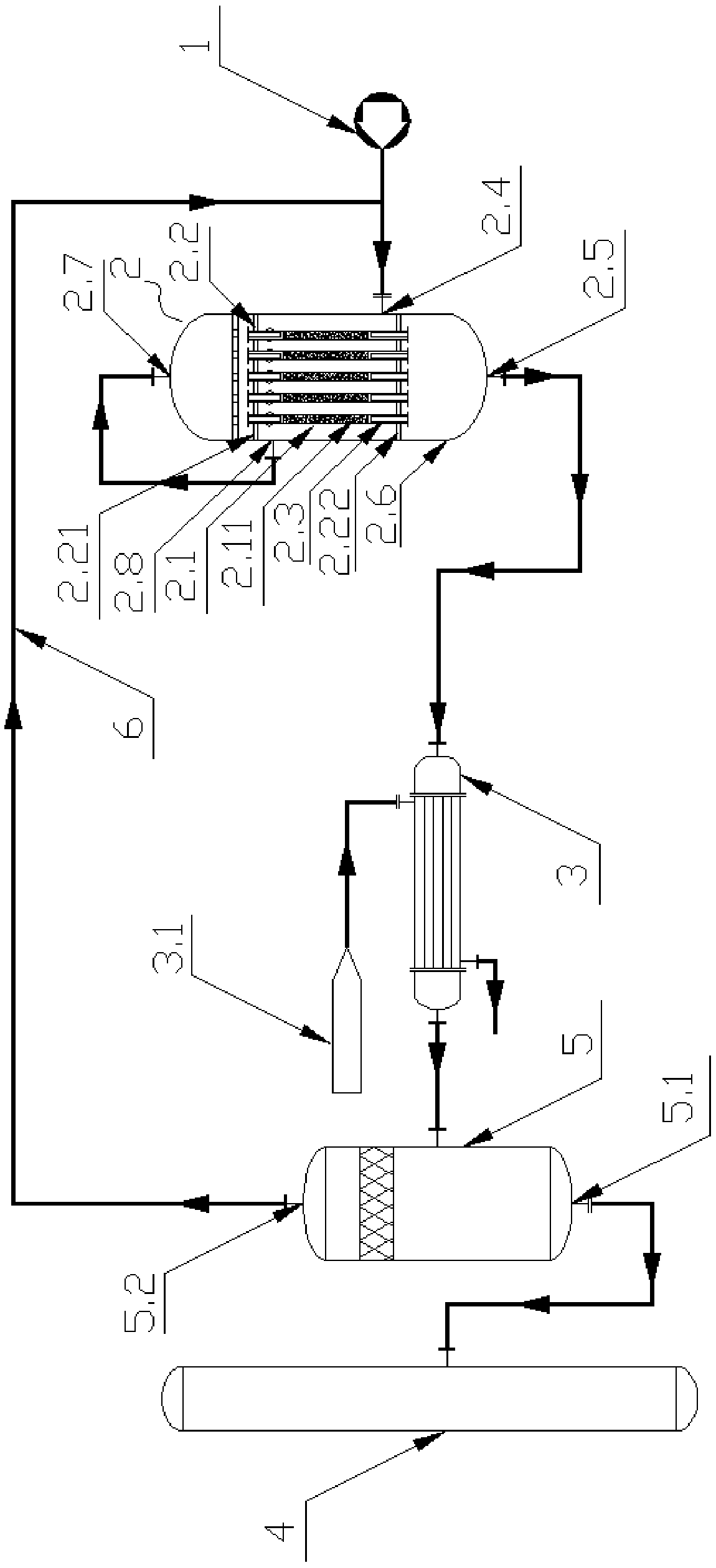

[0067] Step 1: Under the condition of normal temperature and pressure, the mixture raw material of methanol, waste gasoline, waste diesel oil, liquefied gas and heavy alkyne in the raw material tank 1 is directly fed from the feed port 2.4 or Atomization is passed into the tubular reactor 2; there are multiple feed ports 2.4, and the multiple feed ports 2.4 are evenly spaced between the first tube sheet 2.21 and the second tube sheet 2.22, and the multiple feed ports Circumferentially and / or vertically arranged, the circularly distributed feed inlets are used to heat the raw materials evenly, and the vertically distributed feed inlets are used to effectively control the temperature gradient of the reaction; a thermostatic tube asse...

Embodiment 2

[0074] Adopt the hydrocarbon production method of the present invention, use the mixture of methanol mixed with carbon monoxide as raw material to prepare aromatics, comprising the following steps:

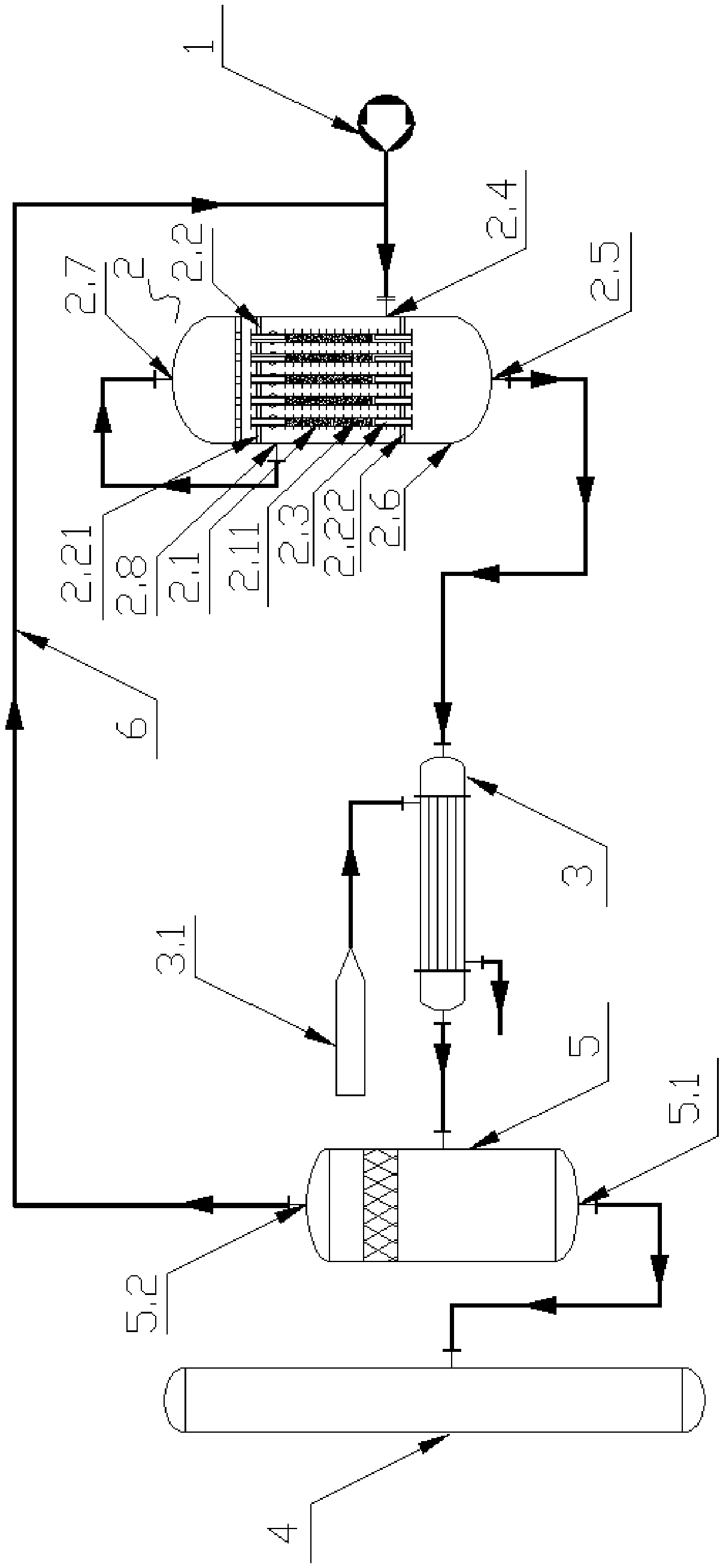

[0075] Step 1: Under normal temperature and pressure conditions, the raw material mixture of methanol and carbon monoxide in the raw material tank 1 is directly passed through the connecting pipeline at a low temperature of less than 100°C from the feed port 2.4 or atomized into the tube-and-tube type Reactor 2; There is one feed port 2.4, and two thermostatic tube assemblies 2.12 are arranged in the tubular reactor 2, and the thermostatic tube 2.1 in the thermostatic tube assembly 2.12 is a finned tube; the catalyst located in the upper thermostatic tube assembly 2.12 It is MTO-100, and the catalyst in the lower thermostatic tube assembly 2.12 is ZSM-5;

[0076] Step 2: The recycle gas 6 output from the gas outlet 5.2 on the gas-liquid separator 5 is input into the tubular reacto...

Embodiment 3

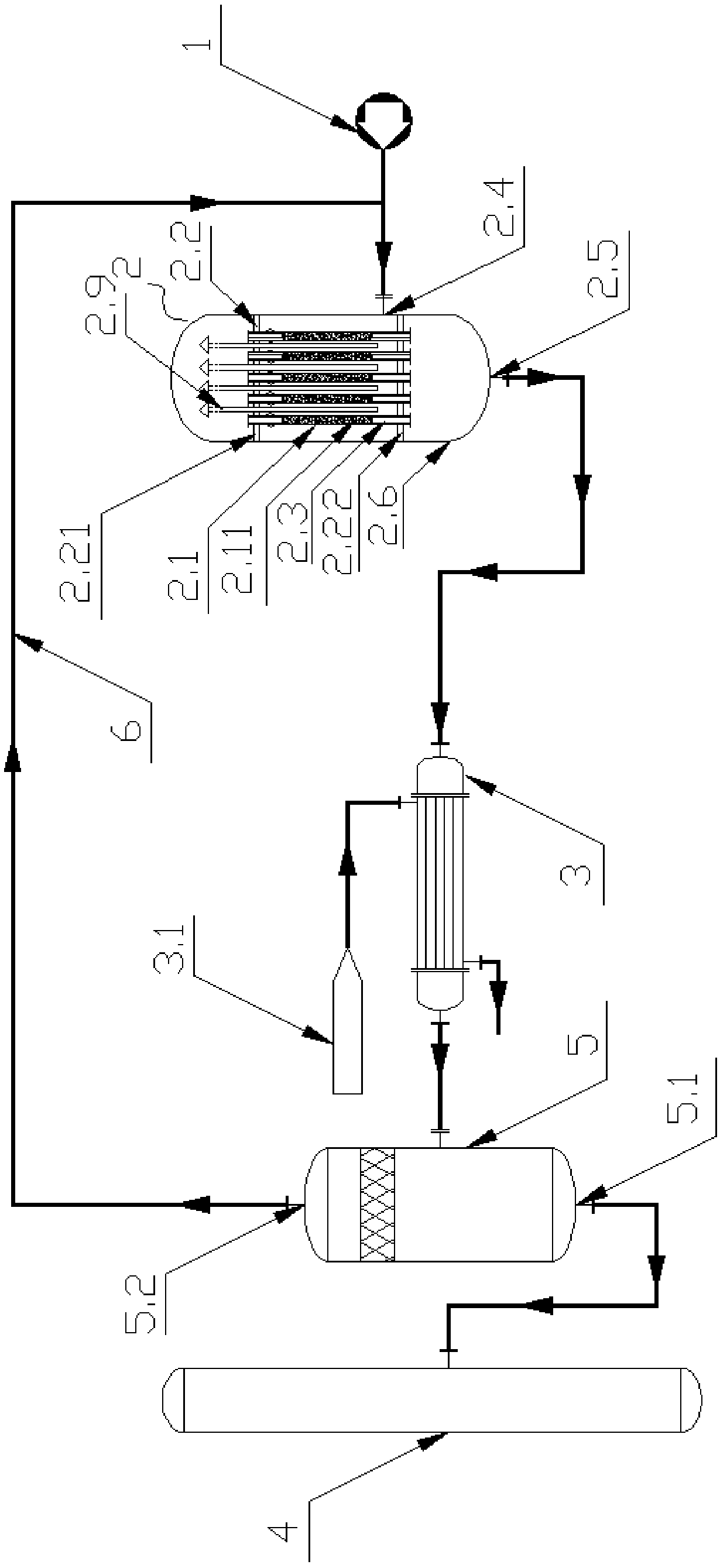

[0082] The hydrocarbon production method is the same as in Example 2, except that there is one feed inlet 2.4; the catalyst in the upper thermostatic tube assembly 2.12 is MTO-100, and the catalyst in the lower thermostatic tube assembly 2.12 is MTO-100 .

[0083] Conclusion: The circulation ratio of recycle gas and raw methanol is less than 1:1; the conversion rate reaches 99% and above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com