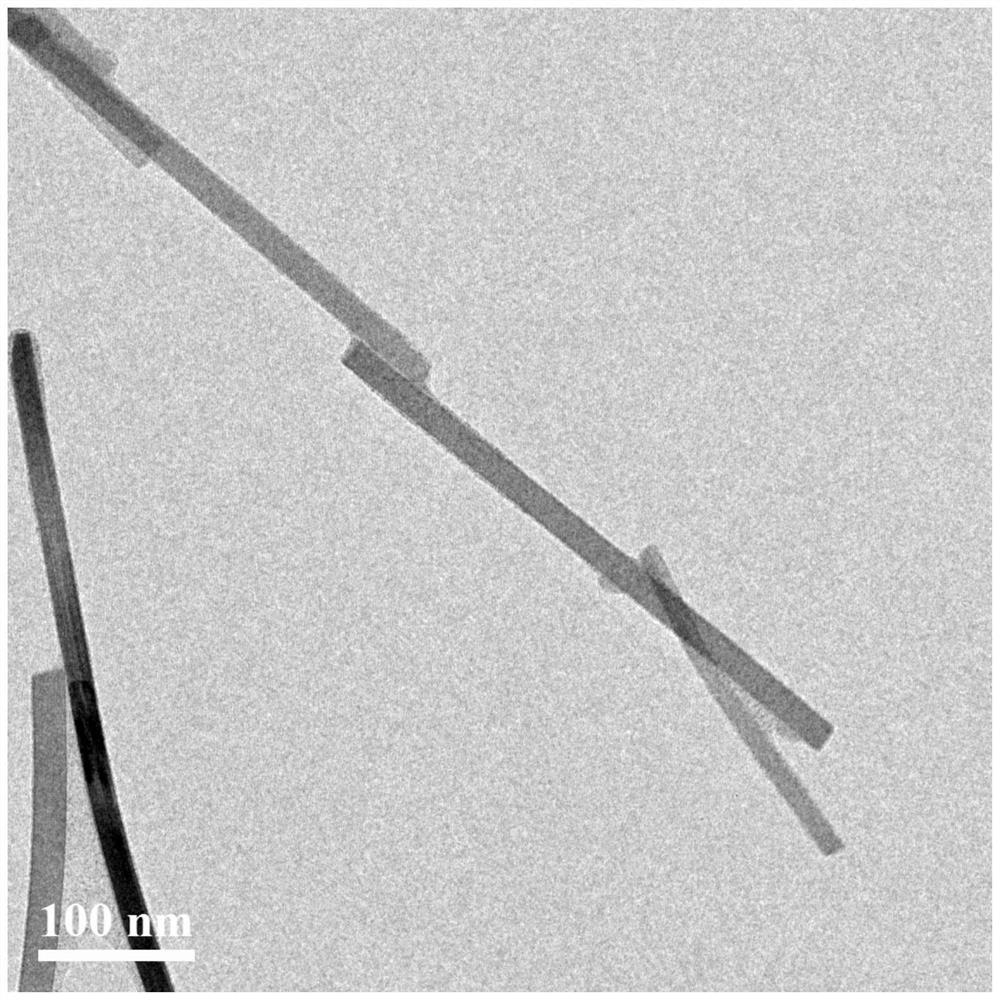

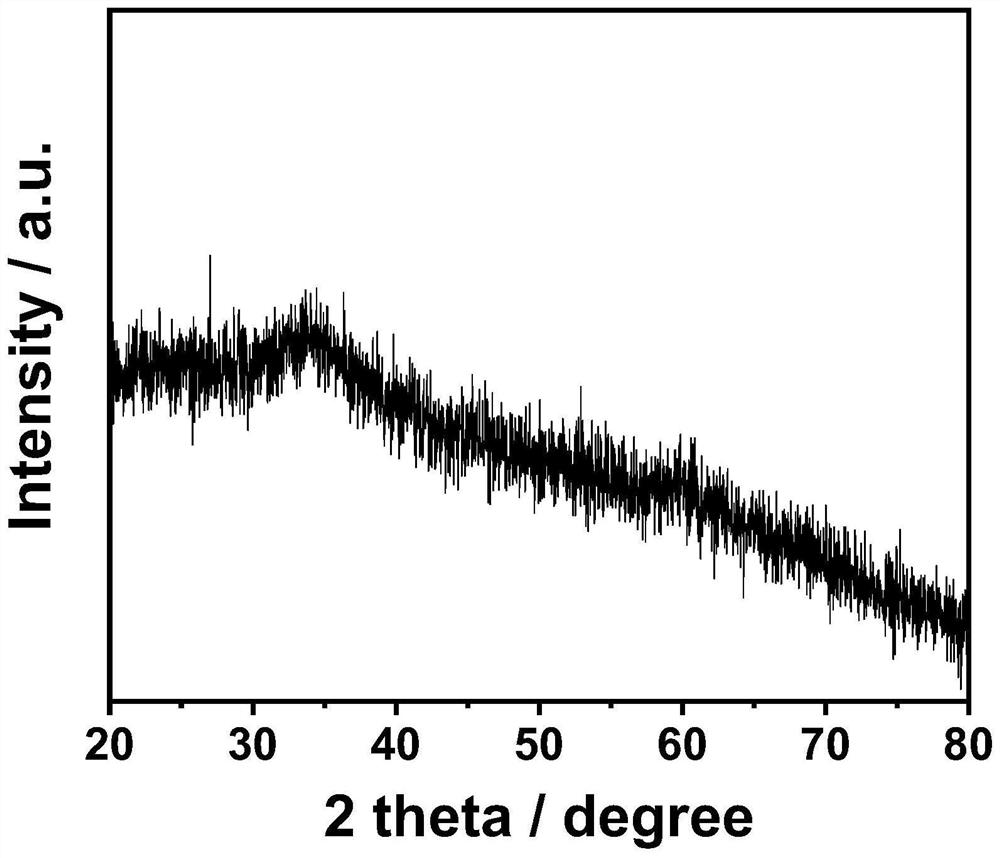

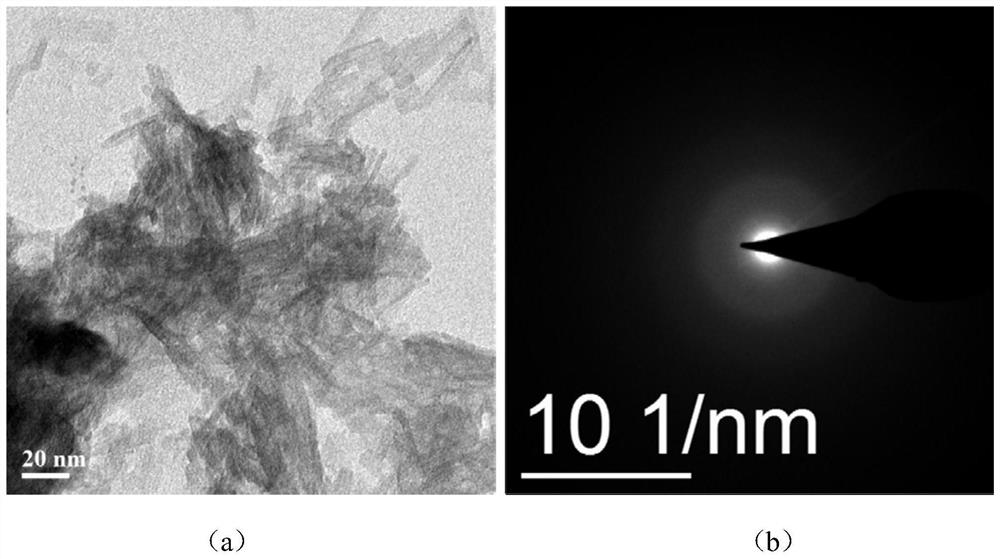

Preparation method and application of amorphous cobalt borate nanorod high-efficiency oxygen evolution electrocatalyst

An electrocatalyst, cobalt nanotechnology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of no patents, academic literature, reports, etc., and achieve excellent Electrochemical performance, effect of low onset overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the preparation method of the amorphous cobalt borate nanorod electrocatalyzed water desorption oxygen catalyst is as follows:

[0037] (1) Weigh 0.04mol cobalt nitrate hexahydrate and add it to 60mL deionized water, and stir magnetically for 10 minutes at room temperature. After it is completely dissolved, add 0.02mol sodium tetraborate decahydrate to the solution, and stir for 30 minutes to completely dissolve to obtain the reaction Precursor solution.

[0038] (2) The reaction precursor solution prepared in step (1) was transferred to a 100 mL polytetrafluoro-lined stainless steel hydrothermal reaction kettle, and heated and reacted at 180° C. for 16 hours.

[0039] (3) After the reaction is completed, after cooling down to room temperature naturally, the obtained reaction precipitates are centrifuged three times with deionized water and ethanol, and each time is centrifuged at 6000rpm for 10 minutes; deionized water, and transferred to a refrigerat...

Embodiment 2

[0042] In this example, the preparation method of the amorphous cobalt borate nanorod electrocatalyzed water desorption oxygen catalyst is as follows:

[0043] (1) Weigh 0.05mol cobalt nitrate hexahydrate and add it to 60mL deionized water, stir magnetically at room temperature for 10 minutes, after it is completely dissolved, add 0.02mol sodium tetraborate decahydrate to the solution, stir for 30 minutes to completely dissolve to obtain the reaction Precursor solution.

[0044] (2) The reaction precursor solution prepared in step (1) was transferred to a 100 mL polytetrafluoro-lined stainless steel hydrothermal reaction kettle, and heated and reacted at 160° C. for 12 hours.

[0045] (3) After the reaction is finished, after cooling down to room temperature naturally, the obtained reaction precipitates are centrifuged and washed three times with deionized water and ethanol, each time at 10,000 rpm for 20 minutes; deionized water and transferred to a refrigerator for 24 hours...

Embodiment 3

[0048] In this example, the preparation method of the amorphous cobalt borate nanorod electrocatalyzed water desorption oxygen catalyst is as follows:

[0049] (1) Use a pipette gun to add 20 μL of perfluorosulfonic acid resin (nafion) solution to 980 μL of ethanol, then weigh 10 mg of amorphous cobalt borate nanorods prepared in Example 1 and add them to the solution, ultrasonically disperse for 1 hour , to obtain a homogeneously dispersed solution.

[0050] (2) Take 10 μL of the dispersion prepared in step (1), drop it onto a glassy carbon electrode with a diameter of 1.2 mm, and dry it by using an infrared lamp for 30 minutes. Repeat the dropwise addition three times to prepare an electrode.

[0051] (3) Use the CHI660 electrochemical workstation to test the electrocatalytic water desorption oxygen performance of the electrode prepared in step (2), wherein the counter electrode is a stone mill rod, the reference electrode is a Hg / HgO electrode, and the electrolyte is KOH wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com