Porcelain-like coating and flexible stone-like tapestry brick

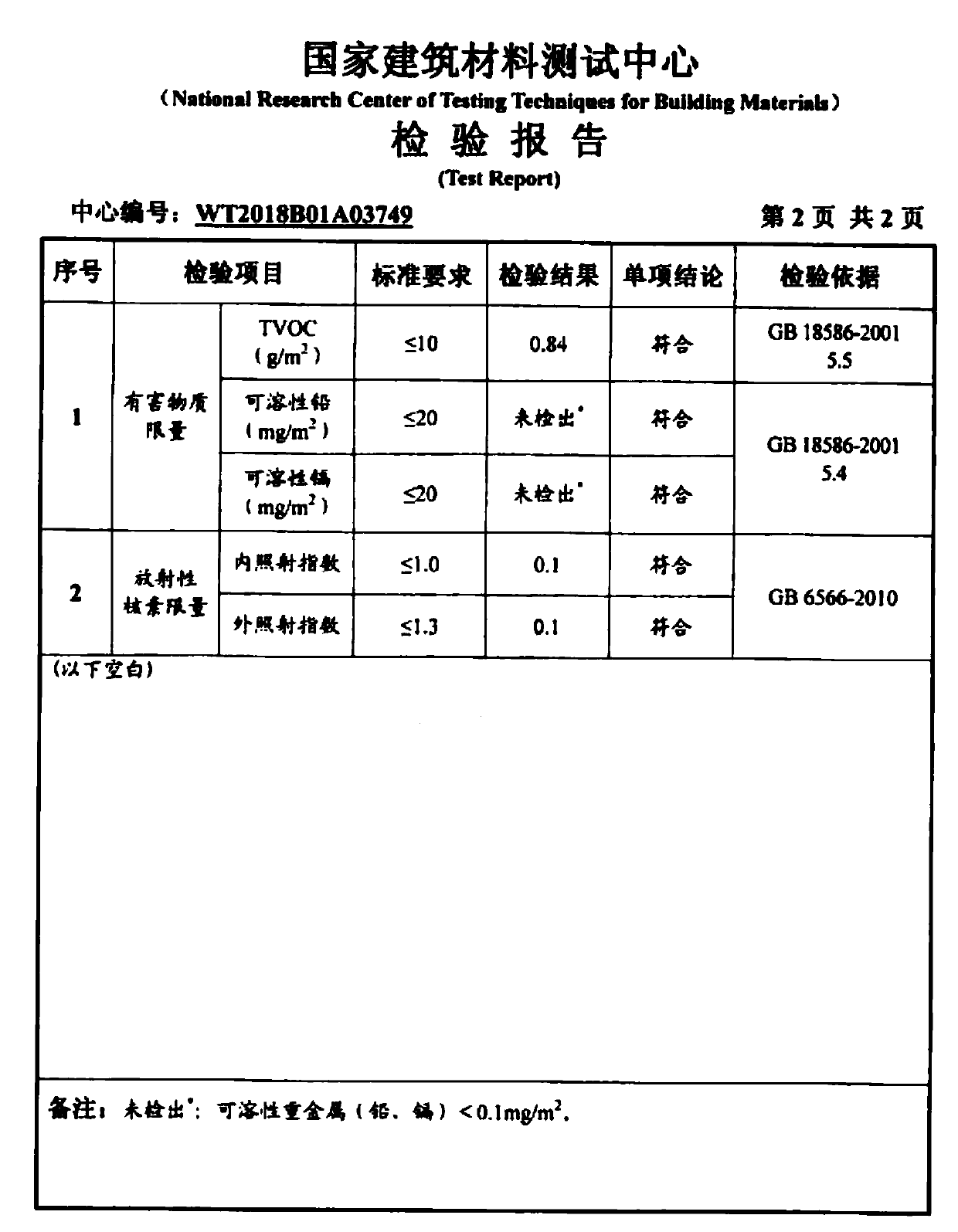

A technology of imitation porcelain paint and decorative bricks, applied in the direction of architecture, building structure, covering/lining, etc., can solve the problems affecting the decoration effect of the entire wall, pollution, etc., and achieve the effect of improving anti-fouling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

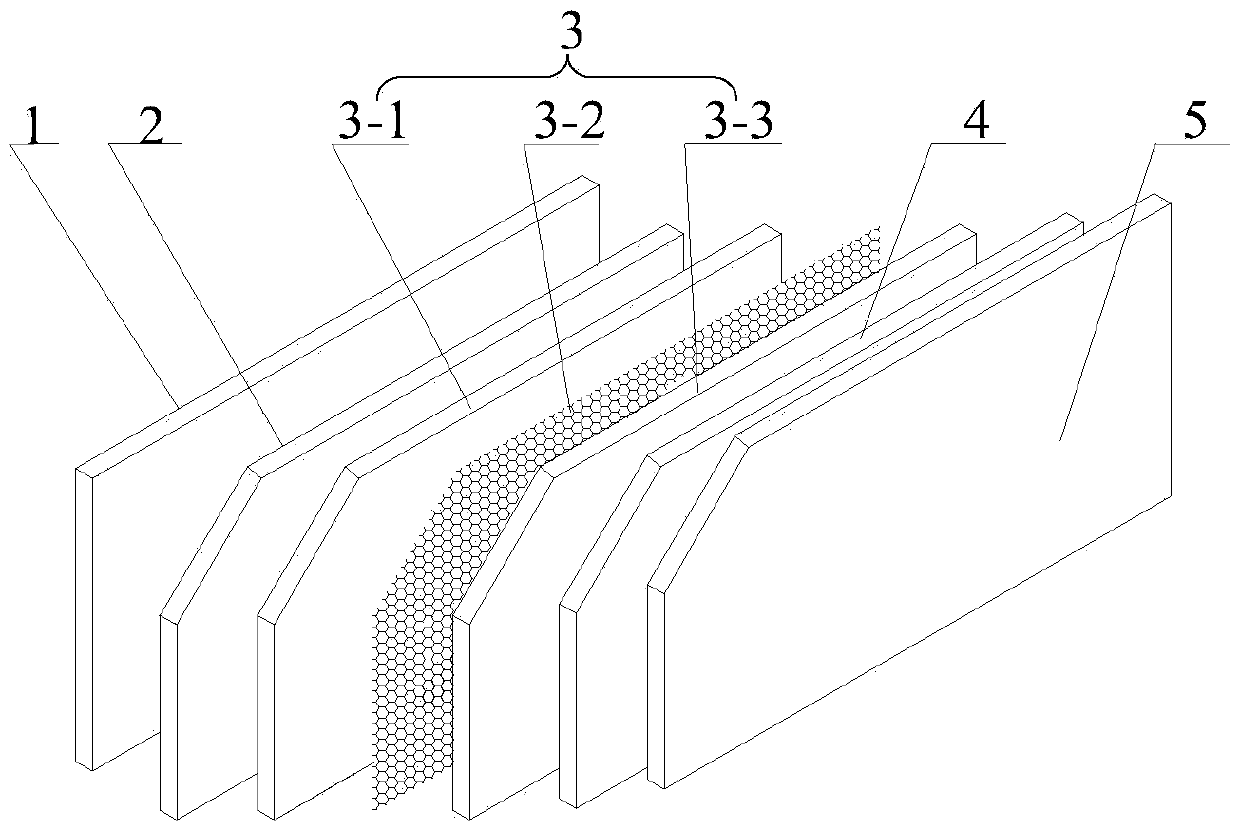

Image

Examples

Embodiment 1

[0041] 15 parts of nano-silicon carbide, 20-35 parts of calcium carbonate, 8-12 parts of loess stone powder, 10-15 parts of sodium oxalate, 0.5-2 parts of hydroxyethyl methylcellulose, 1-3 parts of organic bentonite, 3 parts of binder ~7 parts, 20 to 30 parts of pure water, the particle size of the silicon carbide is 5mm, and the particle size of the quartz sand powder finish layer is 0.3mm.

Embodiment 2

[0043] 20 parts of nano-silicon carbide, 20-35 parts of calcium carbonate, 8-12 parts of loess stone powder, 10-15 parts of sodium oxalate, 0.5-2 parts of hydroxyethyl methylcellulose, 1-3 parts of organic bentonite, 3 parts of binder ~7 parts, 20 to 30 parts of pure water, the particle size of the silicon carbide is 5mm, and the particle size of the quartz sand powder finish layer is 0.3mm.

Embodiment 3

[0045] 25 parts of nano-silicon carbide, 20-35 parts of calcium carbonate, 8-12 parts of loess stone powder, 10-15 parts of sodium oxalate, 0.5-2 parts of hydroxyethyl methylcellulose, 1-3 parts of organic bentonite, 3 parts of binder ~7 parts, 20 to 30 parts of pure water, the particle size of the silicon carbide is 5mm, and the particle size of the quartz sand powder finish layer is 0.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com