Anti-mud slump-loss-resistant multifunctional unsaturated monomer for production of polycarboxylate slump-loss-resistant mother liquor

A technology of unsaturated polycarboxylic acid, which is applied in the field of slump-preserving, slow-release unsaturated functional monomers, and anti-sludge, which can solve the problems of high preparation cost and limited effect of anti-sludge anti-slump, and achieves quick results and is not easy to segregate , reduce the effect of grasping the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Synthesis of anti-mud functional monomer 1:

[0062] (1) Add 738 grams of polyols (sorbitol: ethylene glycol: polyethylene glycol 200: polyethylene glycol 1000 = 20:50:10:20) into a three-necked flask, start heating in an oil bath and Stir.

[0063] (2) Heat up to 40°C, add 0.7 g of polymerization inhibitor (phenothiazine: p-benzoquinone = 60:40), and stir for 5 minutes.

[0064] (3) Heat up to 60°C, add 252.3 g of unsaturated carboxylic acid (acrylic acid: methacrylic acid = 60:40).

[0065] (4) After heating up to 75°C, add 9 grams of catalyst (concentrated hydrochloric acid: p-toluenesulfonic acid = 30:70).

[0066] (5) Heat up to 110°C and keep warm for 2.5 hours.

[0067] (6) Cool to below 60°C and discharge to obtain anti-sludge functional monomer 1.

[0068] This mud-resistant functional monomer 1 is used for the synthesis of the following slump-preserving mother liquor 1.

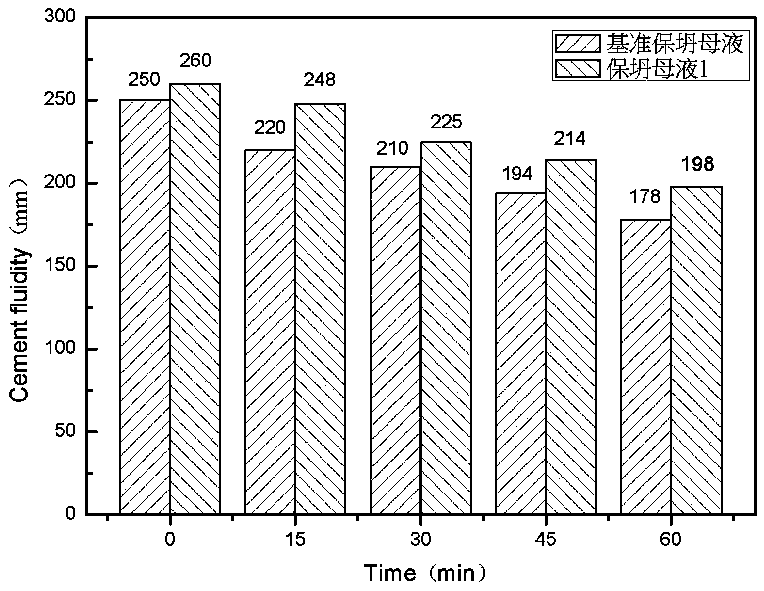

[0069] 2. Synthesis of Baosteel Mother Solution 1:

[0070] (1) Add 365 grams of...

Embodiment 2

[0082] 1. Synthesis of anti-mud functional monomer 1:

[0083] Consistent with that described in Example 1. This mud-resistant functional monomer 1 is also used in the synthesis of the following slump-preserving mother liquor 2.

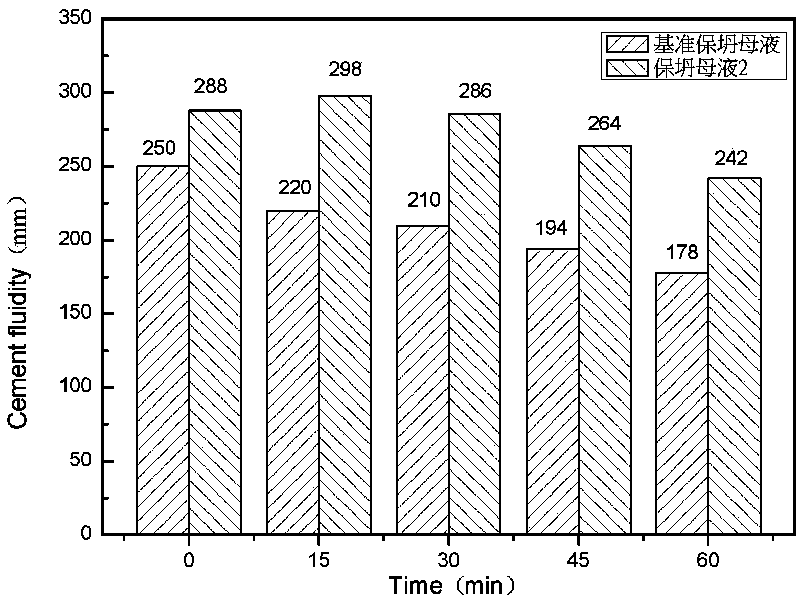

[0084] 2. Synthesis of slump-proof mother liquor 2:

[0085] (1) Add 365 grams of isobutenol polyoxyethylene ether and 350 grams of deionized water into a three-necked flask, and stir at room temperature for 20 minutes to ensure that the isobutenol polyoxyethylene ether is completely dissolved.

[0086] (2) Add 5 grams of hydrogen peroxide and stir for 5 minutes.

[0087] (3) Prepare liquid A and liquid B. Solution A: 1.6 grams of mercaptopropionic acid, 1.4 grams of vitamin C (VC), 82 grams of deionized water. Solution B: 25 grams of acrylic acid, 40 grams of anti-mud functional monomer 1, 23 grams of deionized water. Both liquid A and liquid B are added dropwise into the three-necked flask, wherein liquid A is added dropwise for 3.5 hours, and...

Embodiment 3

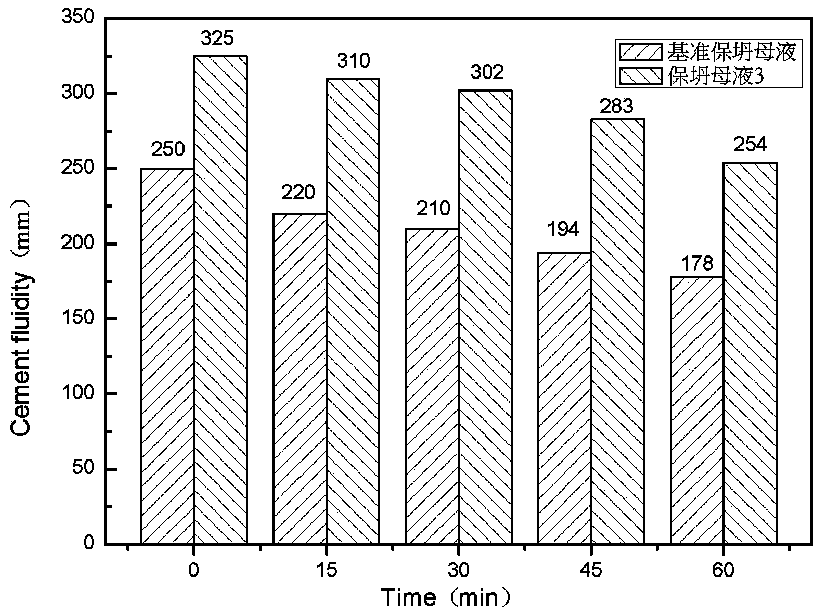

[0093]1. Synthesis of anti-mud functional monomer 2:

[0094] (1) Add 613 grams of polyols (sorbitol: ethylene glycol: polyethylene glycol 600: polyethylene glycol 1500 = 30:30:20:20) into a three-necked flask, start heating in an oil bath and to stir;

[0095] (2) Heat up to 50°C, add 1 g of polymerization inhibitor (2-tert-butylhydroquinone: hydroquinone: p-benzoquinone = 30:20:50), and stir for 5 minutes;

[0096] (3) Heat up to 65°C, add 378 grams of unsaturated carboxylic acid (acrylic acid: methacrylic acid = 30:70);

[0097] (4) After heating up to 80°C, add 8 grams of catalyst (concentrated sulfuric acid: p-toluenesulfonic acid = 40:60);

[0098] (5) Heat up to 135°C and keep warm for 3 hours;

[0099] (6) Cool to below 60°C and discharge to obtain mud-resistant functional monomer 2.

[0100] This mud-resistant functional monomer 2 is used for the synthesis of the following slump-preserving mother liquor 3.

[0101] 2. Synthesis of slump-proof mother liquor 3:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com