Fermentation method for producing N-acetylneuraminic acid

A technology of acetylneuraminic acid and fermentation method, applied in the field of fermentation for producing N-acetylneuraminic acid, can solve problems such as low yield, limited application scope, high cost, etc., and achieve the effects of increasing yield and improving synthesis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

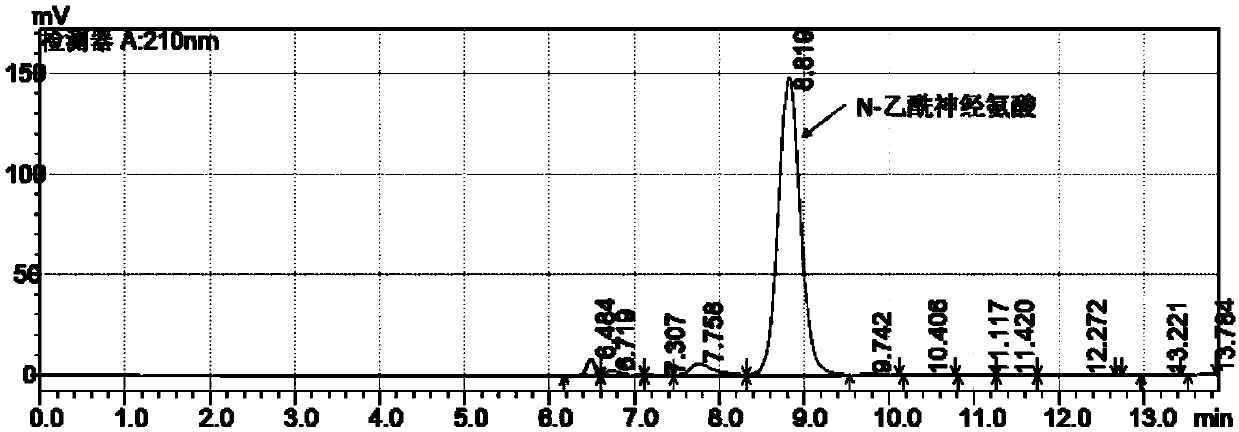

Image

Examples

Embodiment 1

[0042] The fermentation method for producing N-acetylneuraminic acid provided in this embodiment includes the following steps:

[0043] 1 Strain activation:

[0044] The frozen N-acetylneuraminic acid-producing strains (preservation number CCTCC No: M2013494) were streaked and inoculated onto solid LB medium and cultured at 37°C.

[0045] 2 Cultivation of primary seeds:

[0046] When a single bacteria grows out, pick a single colony, inoculate it into an Erlenmeyer flask containing 50 mL of liquid LB seed medium, and cultivate it overnight at 37°C at 200 rpm to obtain a first-level seed liquid.

[0047] 3 Cultivation of secondary seeds:

[0048] The first-level seed liquid was inoculated into an Erlenmeyer flask containing 50 mL of liquid seed culture medium at an inoculum of 1%, and incubated at 200 rpm and 37° C. for 6 hours to obtain a second-level seed liquid.

[0049] The liquid LB medium contains: peptone 10g / L, yeast extract powder 5g / L, sodium chloride 10g / L, pH 7.0.

[0050] The s...

Embodiment 2

[0066] The fermentation method for producing N-acetylneuraminic acid provided in this embodiment is basically the same as that of Embodiment 1, except that the feed solution in this embodiment contains 50% glycerol and 2.5% N-acetylglucosamine.

[0067] The results showed that the NeuAc yield was 82.3g / L and the average synthesis rate was 16.46g / L*12h after 60h of fermentation using the fermentation method of this example.

Embodiment 3

[0069] The fermentation method for producing N-acetylneuraminic acid provided in this example is basically the same as that in Example 1, except that the feed solution in this example contains 50% glycerol and 1% polyphosphoric acid.

[0070] The results showed that the NeuAc yield was 76.8 g / L and the average synthesis rate was 15.36 g / L*12h after 60 hours of fermentation using the fermentation method of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com