Softener of lotus root fiber and use method of softener

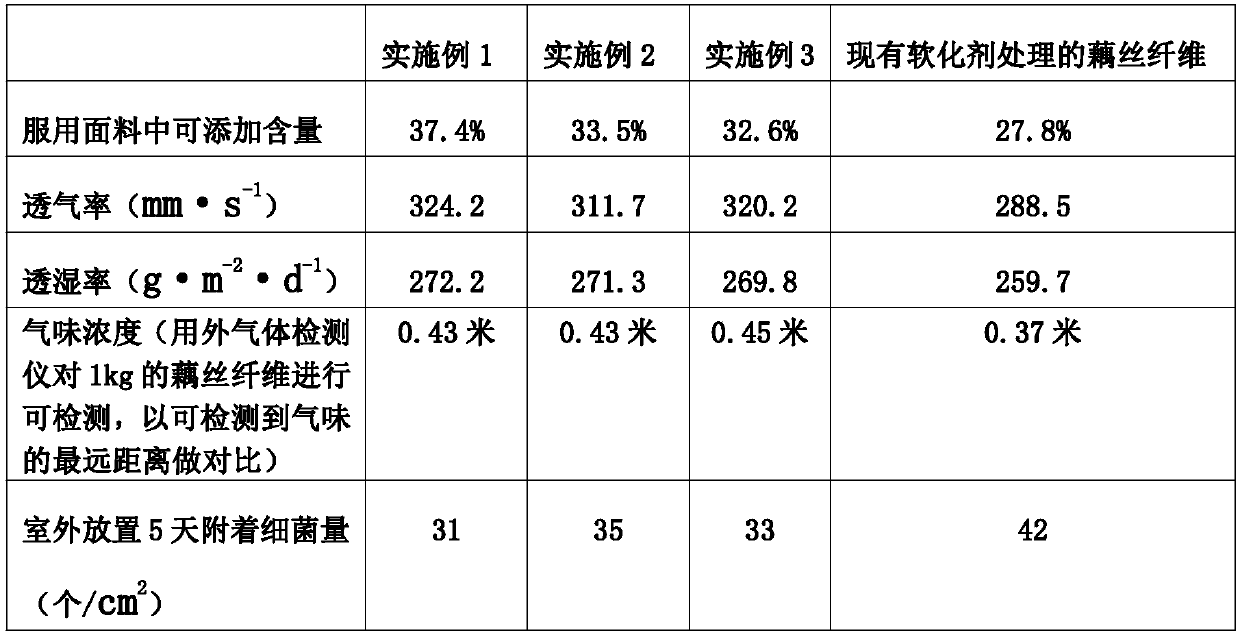

A softener and fiber technology, applied in the field of lotus root silk fiber, can solve the problems of reducing air permeability and anti-mildew and sterilizing functions of lotus root silk fiber, poor softening effect, and small increase in the blending ratio of lotus root silk fiber, so as to achieve the purpose of retaining air permeability and Anti-mold and bactericidal function, retain deodorization function, good softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 (best embodiment). A softener for lotus root fiber, comprising the following raw materials in parts by weight, 45 parts of wood vinegar, 7 parts of butanediol, 10 parts of sodium lauryl sulfate, 15 parts of sulfonic acid, 5 parts of cellulase, lithium chloride 2 parts, 3 parts of amylase, 450 parts of water.

[0020] The using method of the softening agent of lotus root fiber, comprises the following steps,

[0021] a. Mix cellulase, amylase and 65 parts of water and stir evenly to obtain product A,

[0022] b. Spray product A on the silk fiber of lotus root, place the silk fiber of lotus root in an airtight container, heat it to 35°C, and let it stand for 3 days to get product B.

[0023] c. Ultrasonic cleaning of product B, and drying to obtain product C.

[0024] d. Mix wood vinegar, butylene glycol, sodium lauryl sulfate, sulfonic acid, lithium chloride and the remaining water, and stir evenly to obtain product D.

[0025] e. Soak product C into pro...

Embodiment 2

[0027] Example 2. A softener for lotus root fiber, comprising the following raw materials in parts by weight, 40 parts of wood vinegar, 10 parts of butanediol, 8 parts of sodium lauryl sulfate, 20 parts of sulfonic acid, 3 parts of cellulase, lithium chloride 3 parts, 2 parts of amylase, 500 parts of water.

[0028] The using method of the softening agent of lotus root fiber, comprises the following steps,

[0029] a. Mix cellulase, amylase and 50 parts of water and stir evenly to obtain product A,

[0030] b. Spray product A on the lotus root silk fiber, place the lotus root silk fiber in an airtight container, heat it to 30°C, and let it stand for 2 days to get product B.

[0031] c. Ultrasonic cleaning of product B, and drying to obtain product C.

[0032] d. Mix wood vinegar, butylene glycol, sodium lauryl sulfate, sulfonic acid, lithium chloride and the remaining water, and stir evenly to obtain product D.

[0033] e. Soak product C into product D for 1 day to obtain ...

Embodiment 3

[0035] Example 3. A softener for lotus root fiber, characterized in that it comprises the following raw materials in parts by weight, 50 parts of wood vinegar, 4 parts of butanediol, 12 parts of sodium lauryl sulfate, 10 parts of sulfonic acid, and 8 parts of cellulase , 1 part of lithium chloride, 4 parts of amylase, and 400 parts of water.

[0036] The using method of the softening agent of lotus root fiber, comprises the following steps,

[0037] a. Mix cellulase, amylase and 80 parts of water and stir evenly to obtain product A,

[0038] b. Spray product A on the silk fiber of lotus root, place the silk fiber of lotus root in an airtight container, heat it to 40°C, and let it stand for 4 days to get product B.

[0039] c. Ultrasonic cleaning of product B, and drying to obtain product C.

[0040] d. Mix wood vinegar, butylene glycol, sodium lauryl sulfate, sulfonic acid, lithium chloride and the remaining water, and stir evenly to obtain product D.

[0041] e. Soak prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com