Boiler smoke exhaust purification system

A purification system and boiler technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as insufficient contact between gas and desulfurization slurry, increased workload and maintenance costs, and failure to achieve desulfurization and dust removal effects. , to achieve the effect of good desulfurization and denitrification, prevention of secondary pollution, and thorough purification of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

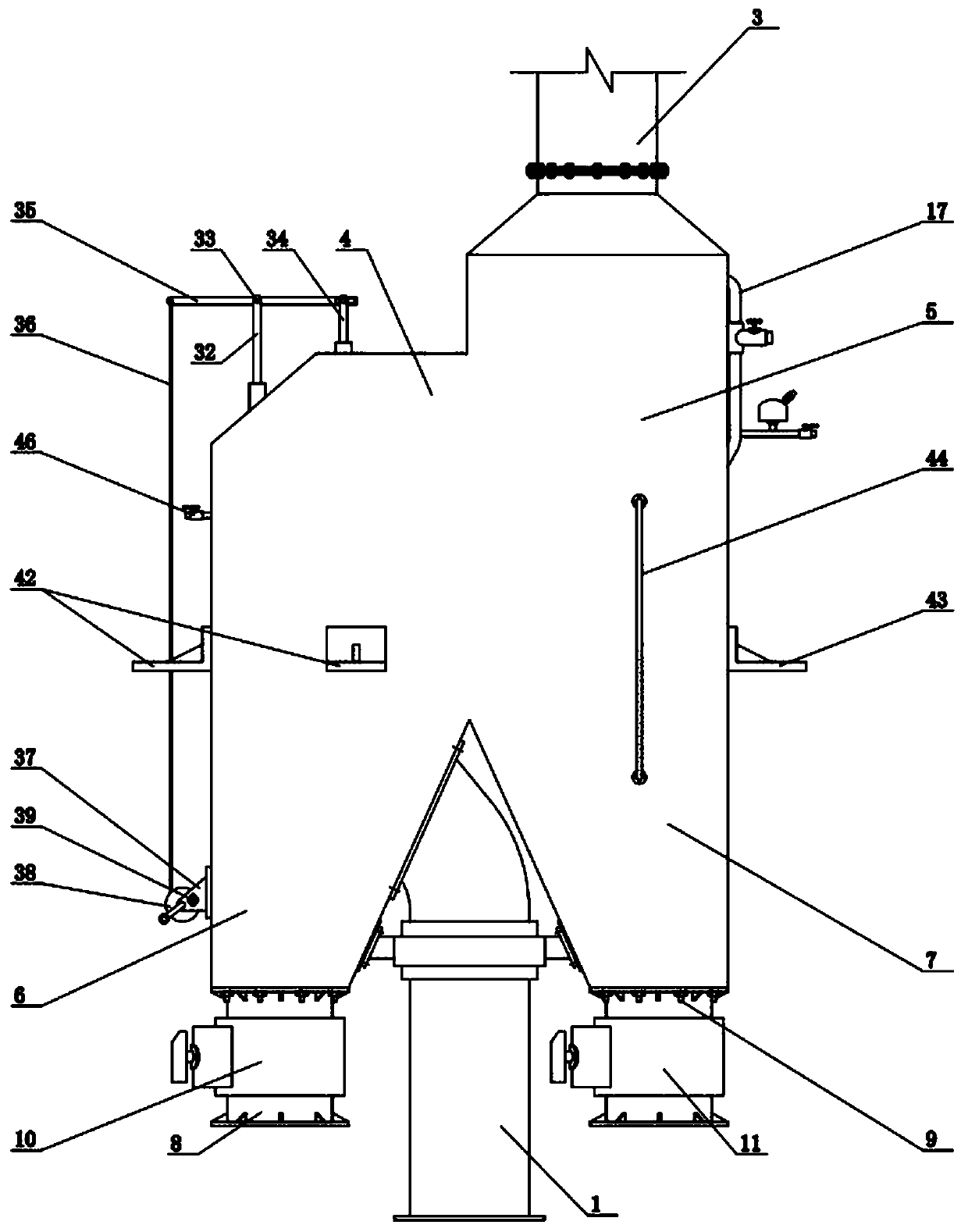

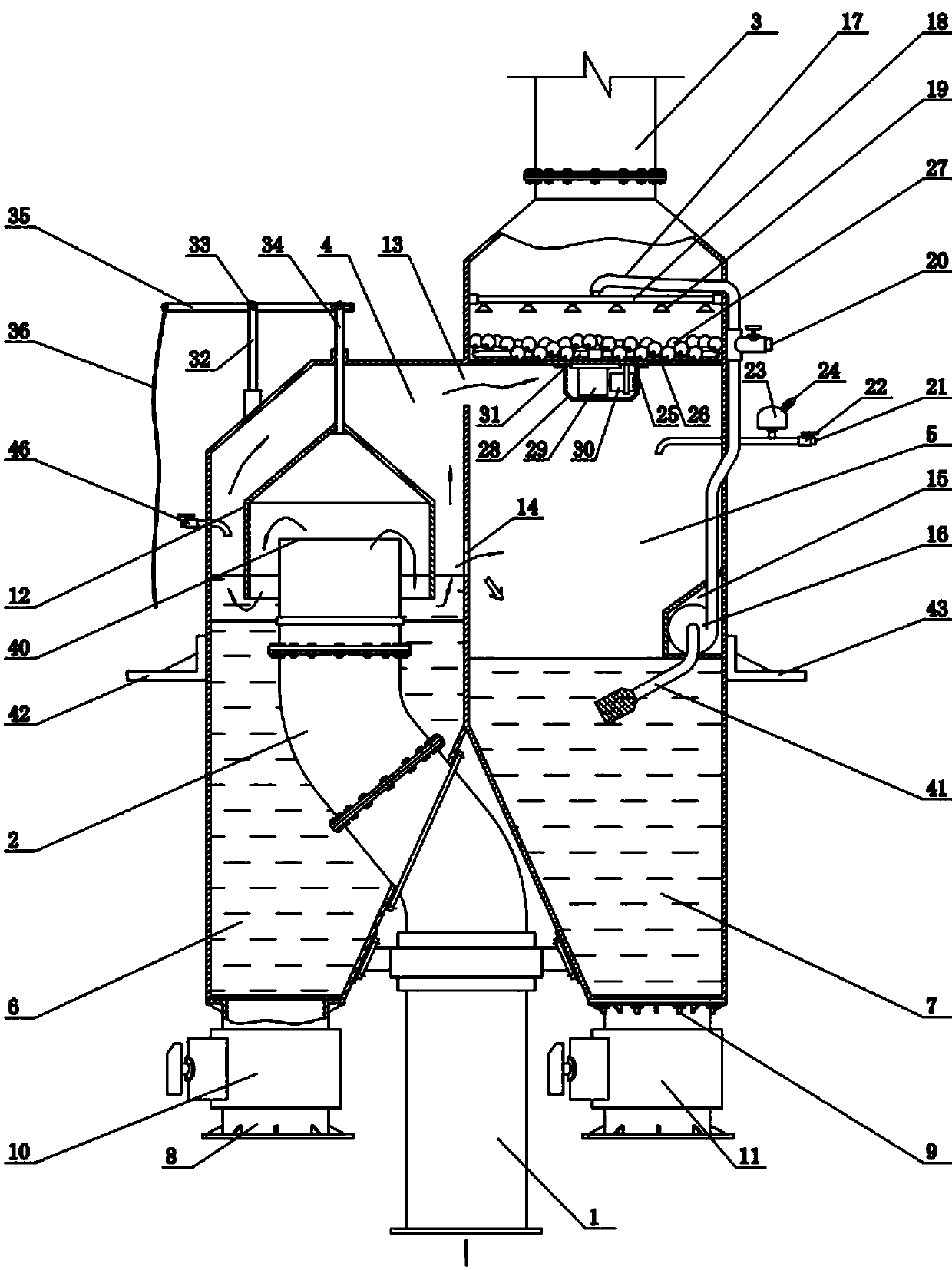

[0022] Embodiment 1: as figure 1 The shown boiler exhaust purification system, its main body includes a dust removal chamber 4 and a desulfurization and denitrification chamber 5, the dust removal chamber bracket 42 and the desulfurization and denitrification chamber bracket 43 are arranged on both sides of the main body, and are fixed and installed on the boiler chimney 3 through the brackets 37 on both sides. The fixed frame (fixed frame is not shown in the figure) provided on both sides of the exhaust outlet of the boiler, wherein the smoke inlet joint 1 is connected to the exhaust outlet of the boiler, the outlet of the silt discharge channel 8 and the outlet of the sewage discharge channel 9 are respectively connected to the silt discharge pipe Sealed with the sewage pipe. The whole system is easy to install. After installation, add water to the dedusting chamber 4 and add alkali to the desulfurization and denitrification chamber 5, and adjust the height of the air pressu...

Embodiment 2

[0028] Embodiment 2: On the basis of Embodiment 1, the similarities will not be repeated. The difference is that a smoke washing mechanism is arranged in the desulfurization and denitrification chamber 5, which is the upper part of the desulfurization and denitrification chamber 5 and the lye spraying mechanism The lower part is provided with a flat carrier plate 25, and there is an annular mesh layer 26 around the flat carrier plate 25, and a layer of smoke washing balls 27 is laid on the upper side of the flat carrier plate 25 and the annular mesh layer 26. The smoke washing mechanism also includes a smoke washing ball 27 stirring mechanism, a sealing cover 28 is fixed below the flat carrier plate 25, a gearbox 29 and a motor 30 are fixed in the sealing cover 28, the input end of the gearbox 29 is connected with the rotating shaft of the motor 30, and the gearbox 29 After the output end vertically passes through the central hole provided by the flat carrier plate 25, a stirri...

Embodiment 3

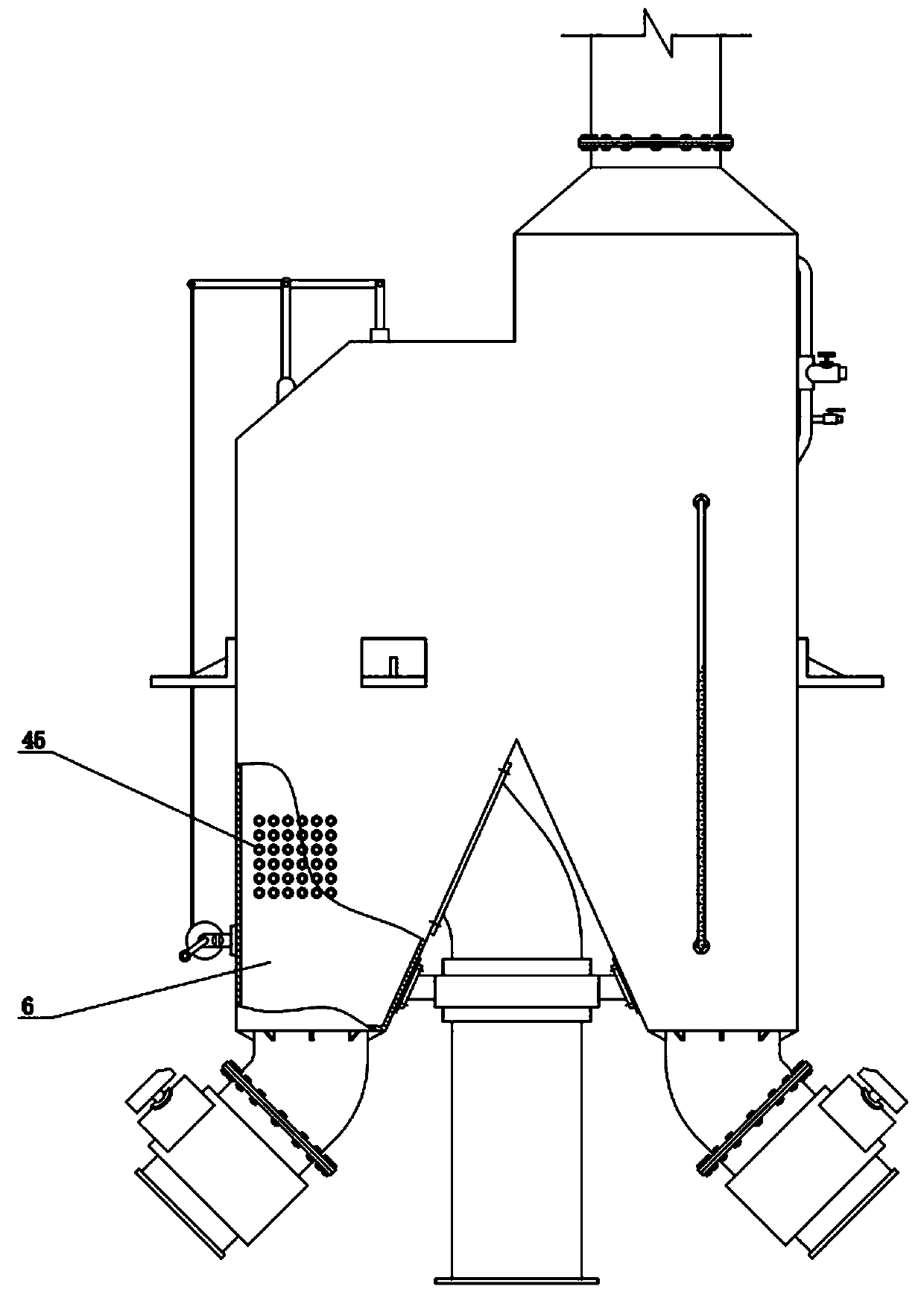

[0030] Embodiment 3: On the basis of Embodiment 1, the similarities are not repeated, and the difference is that the present embodiment adopts such as image 3 As shown, a heat exchange structure is set in the dust removal chamber 4, and a plurality of heat exchange pipes 45 run through the dust removal chamber 4, which can be used to heat the boiler inlet water. The output passes through to preheat the cold water, or preheat the boiler inlet, and reuse the heat energy discharged from the chimney.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com