Planar reflective array antenna

A planar reflectarray and antenna technology, which is applied to antennas, electrical components, waveguide horns, etc., can solve the problems of insufficient stability of the microstrip dielectric layer structure, lower gain, and influence on phase compensation, so as to improve the environmental adaptability of the antenna and reduce the Influence of element coupling and effect of canceling the influence of antenna performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

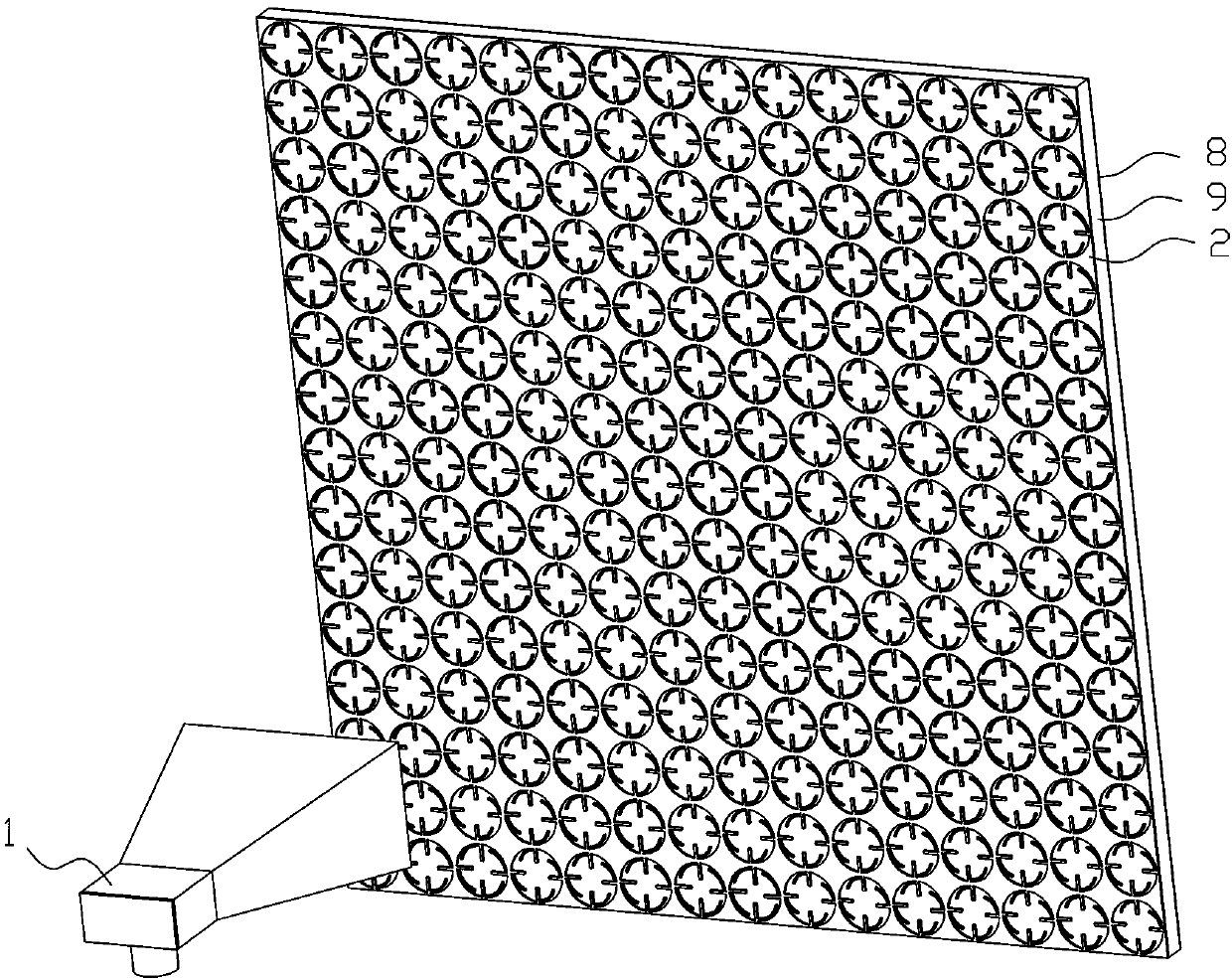

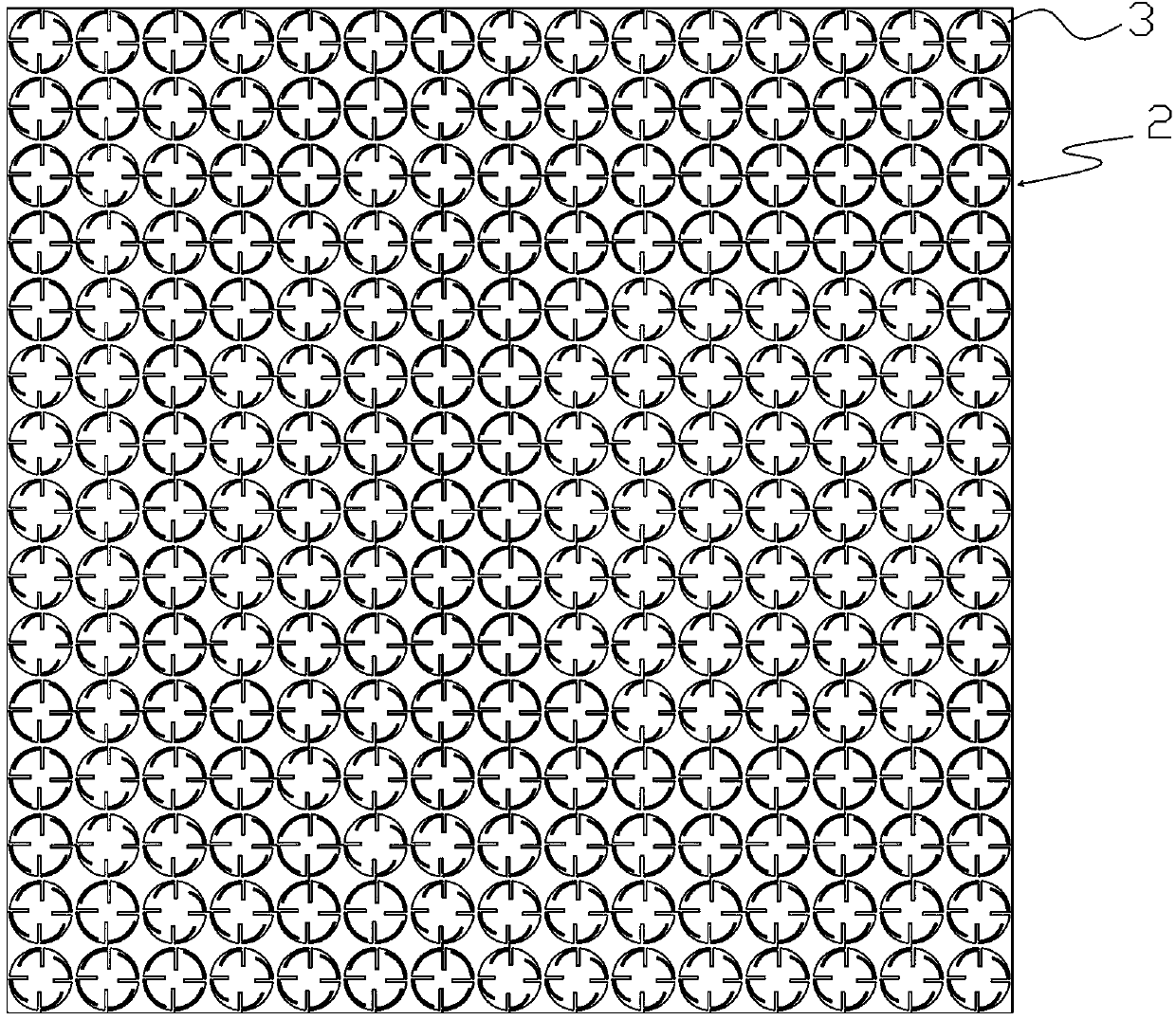

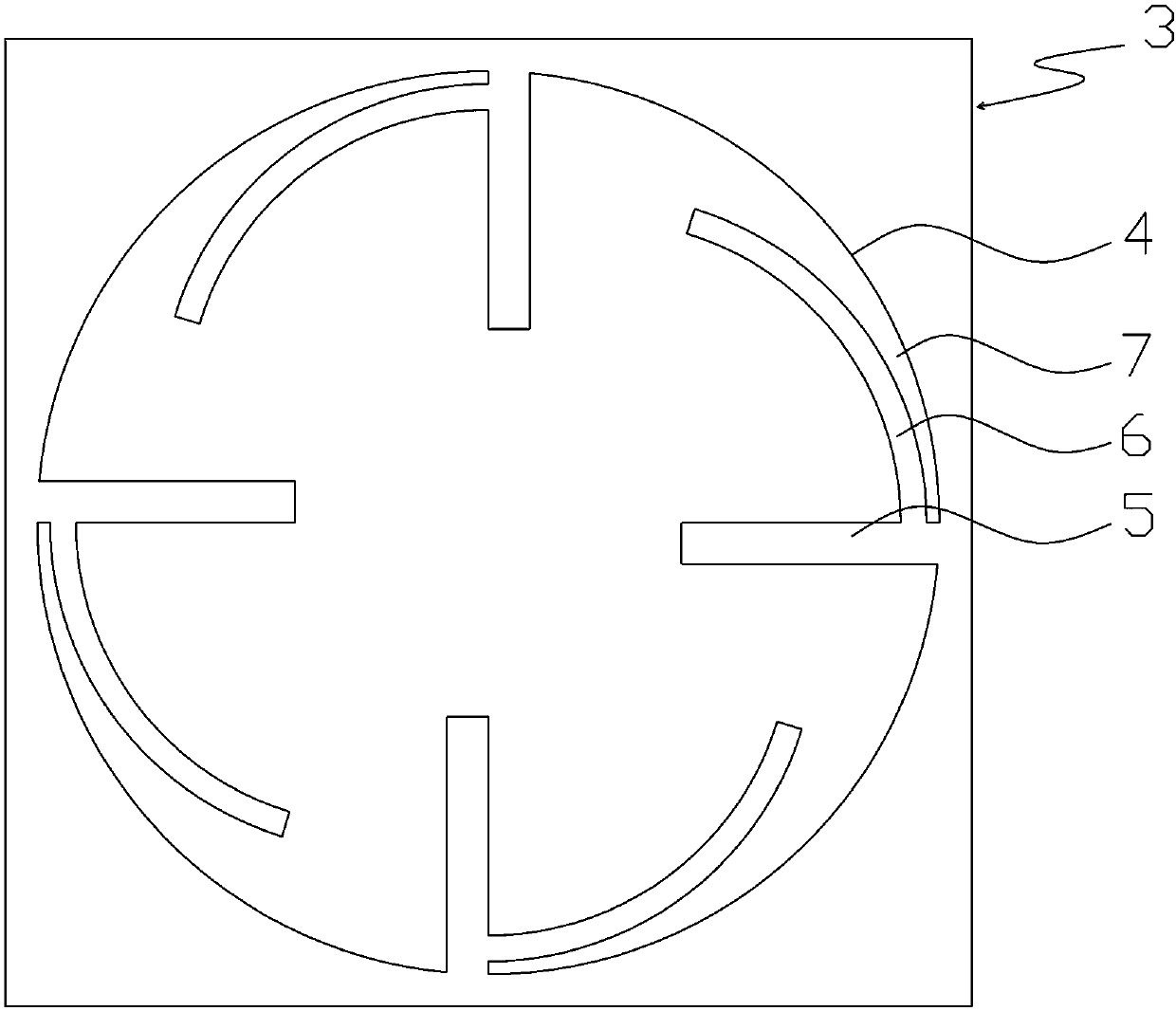

[0038] refer to Figure 1 to Figure 4 As shown, the planar reflectarray antenna of the present invention includes a feed 1 and a conductive planar reflectarray 2 . The feed 1 is used for transmitting or receiving electromagnetic waves. The conductive planar reflection front 2 is preferably square, but it is not limited thereto. It is used to scatter the electromagnetic wave emitted by the feed source 1 into a plane wave, or receive the plane wave and converge it to the feed source, or it can be applied to any need Applications where electromagnetic waves gather. Several identical reflective units 3 are distributed in an array on the conductive flat reflective front 2 . The reflection unit 3 includes a phase hole 4 and four branches distributed on the phase hole 4 , and adjacent reflection units 3 share a frame. A branch 6 with the same direction extends from one side of the branch 5 , and the branch 6 extends along the direction close to the edge of the phase hole 4 , formi...

Embodiment 2

[0053] refer to Figure 5 to Figure 6 As shown, in the planar reflectarray antenna of the present invention, on the basis of Embodiment 1, another preferred solution of the phase hole 4 of the reflective unit 3 is square. The branches 5 are distributed on or near the included angle of the phase hole 4 , and the branches 5 are preferably evenly distributed on the phase hole 4 in a non-centrosymmetric manner. The branches 6 are linear, and when the phase is adjusted, the branches 5 extend toward the center of the phase hole 4, and the branches 6 extend along the edge of the phase hole 4, wherein the branches 6 are far from the edge of the phase hole 4 The smallest part of the gap is less than one-tenth of the working wavelength. The effect similar to the circular structure can also be achieved through the above scheme. Note that the central direction of the square phase hole 4 is its diagonal intersection position, and the non-centrosymmetric distribution of branches means tha...

Embodiment 3

[0055] refer to Figure 7 As shown, in the planar reflectarray antenna of the present invention, on the basis of Embodiment 2, the branch 6 can extend from the phase hole 4 and extend along the direction of the phase hole 4, and its starting end is close to the Branches 5. Effects similar to those of Embodiment 1 and Embodiment 2 can also be achieved through the above scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com