Horizontal spiral stirring leaching tank, its tank group and leaching method

A leaching tank and horizontal technology, which is applied in the field of extraction and production of natural medicines, can solve the problems of complex operation, multiple equipment, and low separation efficiency, and achieve the effects of increasing specific surface area, increasing resource value, and increasing mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

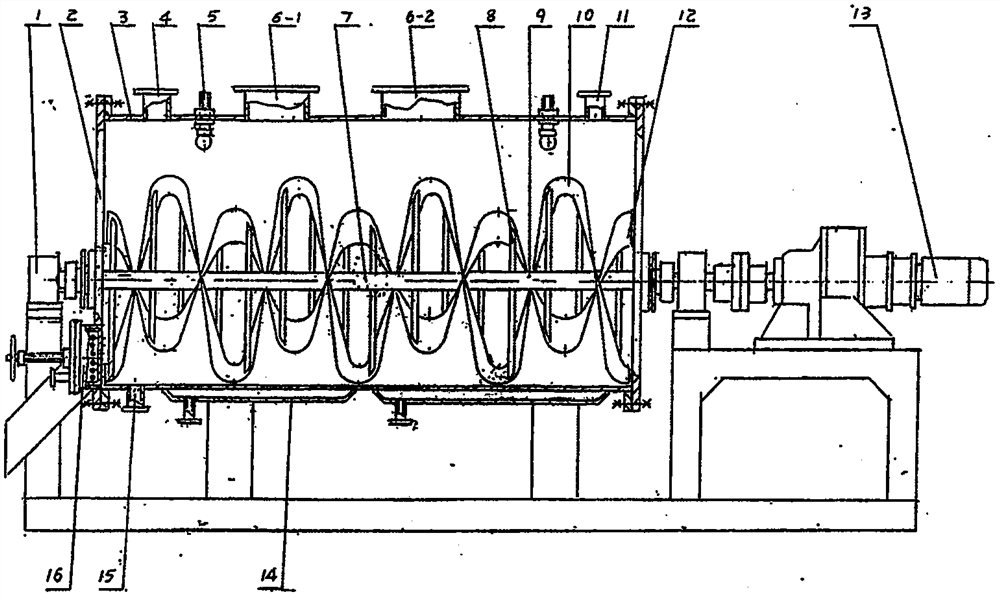

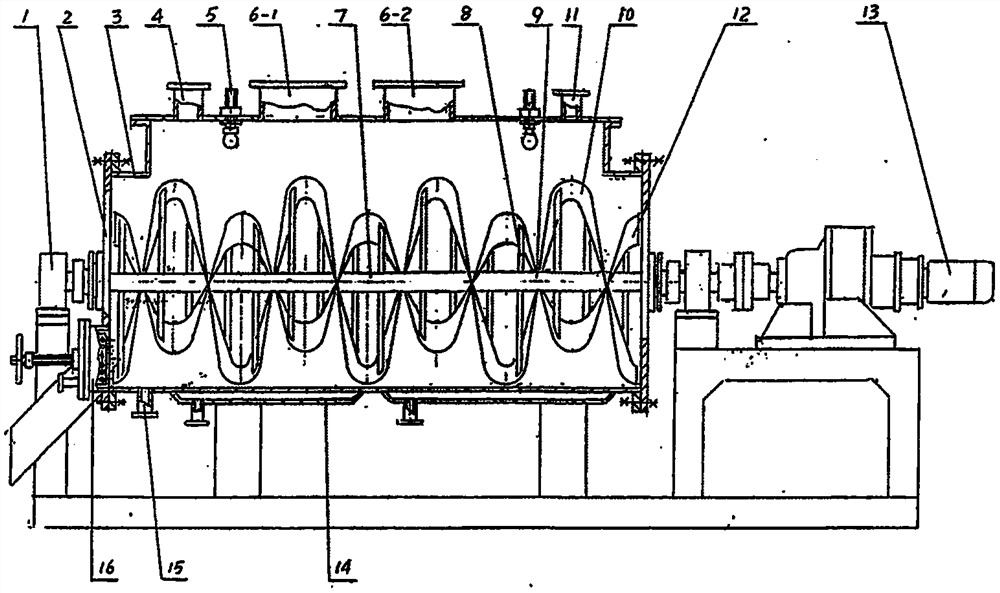

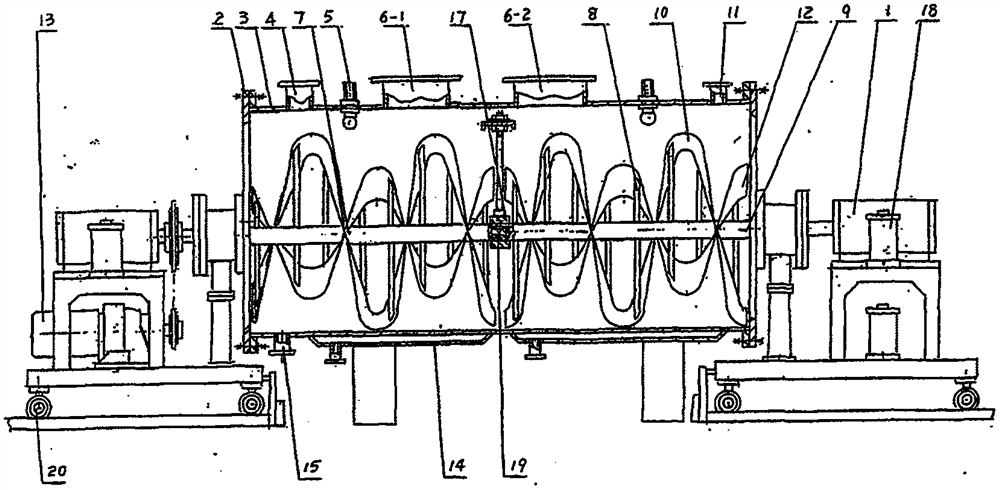

[0019] Depend on figure 1 , 2, 5, a horizontal spiral stirring leaching tank and its tank group, which includes a tank body 3 with a jacket 14, an agitator 7 connected to a drive mechanism 13, a feed inlet 6, a liquid inlet 11, and a steam outlet 4 , cleaning port 5, feed liquid outlet 15, etc. The tank body 3 is a horizontal cylinder with a jacket 14 or a tank with a U-shaped cross section with flange covers 2 at both ends, and the agitator 7 is formed by the passing method. The shaft 9 of the shaft hole of the blue cover 2, the support rod 8, and the ribbon-shaped spiral blades 10 and 12 are composed. The agitator 7 adopts a double-layer spiral ribbon blade structure. The outer spiral blade 10 turns and pushes the solid particles in the feed liquid from one end to the feed liquid outlet 15, while the inner spiral blade 12 turns and pushes the solid particles in the opposite direction. In addition to single-tank leaching, when a double-tank tank group leaching is set, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com