Fully-automatic assembly device of FPC connector

A fully automated, assembly equipment technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of low assembly efficiency, unreasonable structural design, unreliable assembly of flip cover and rubber core, etc., to improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

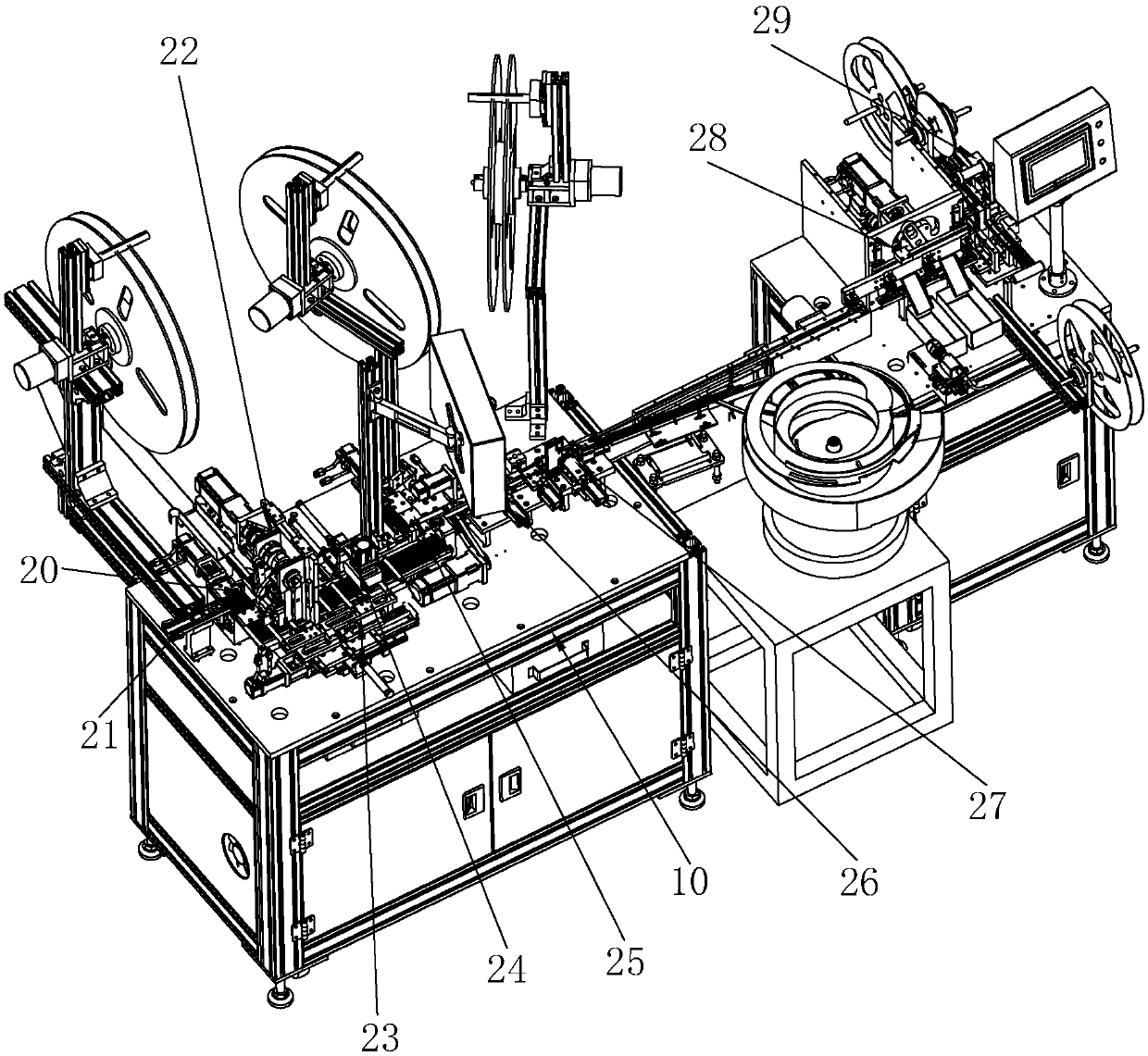

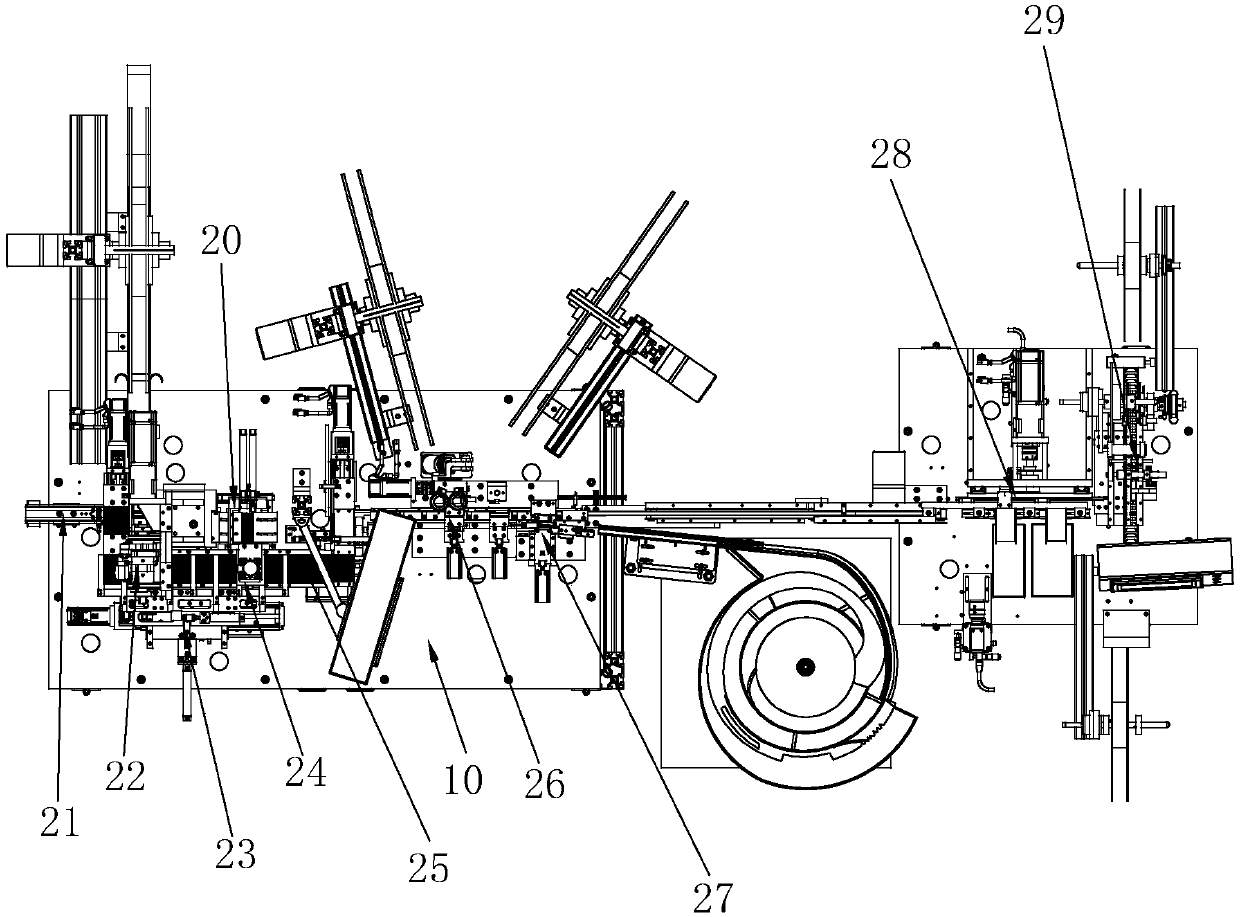

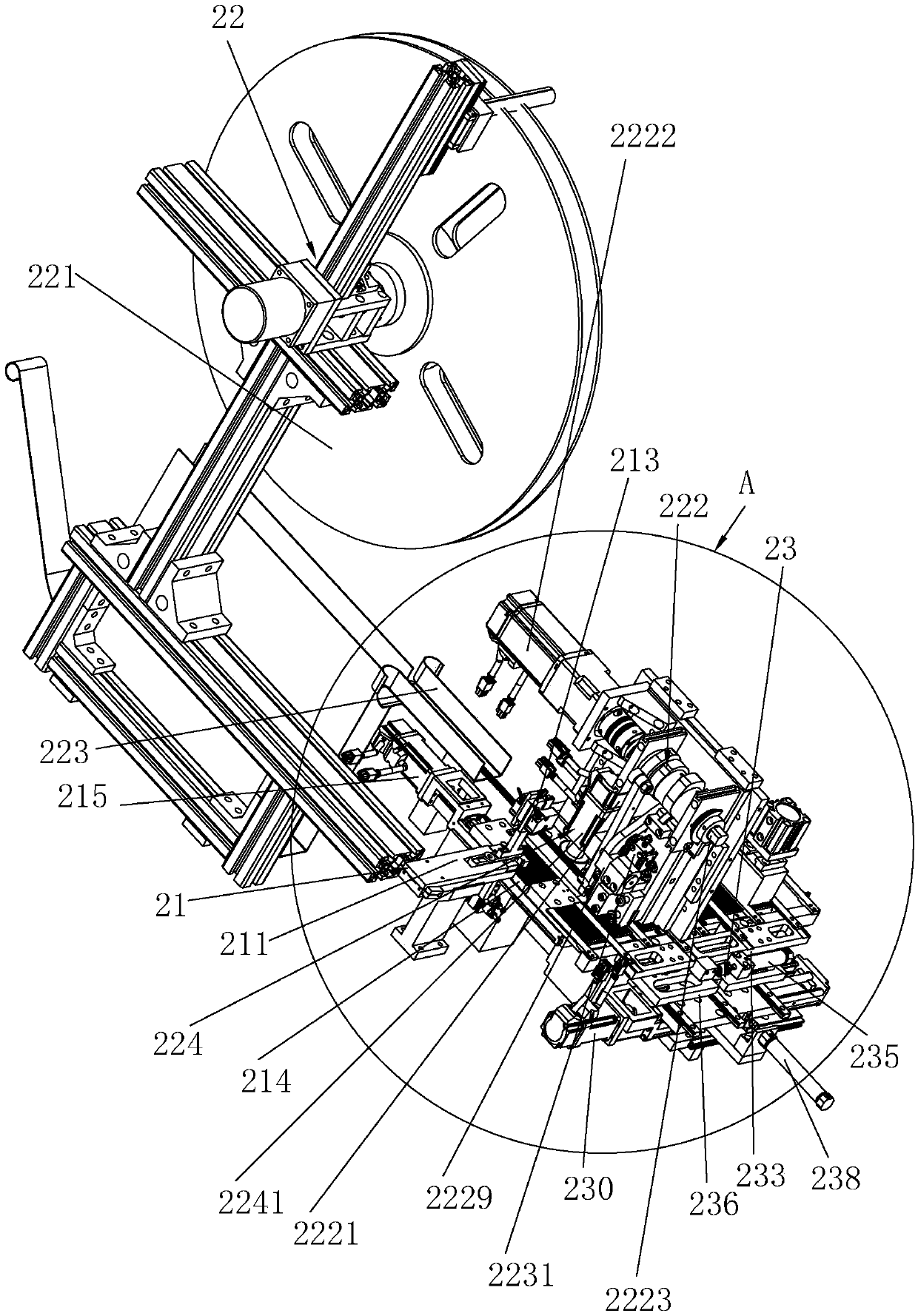

[0017] Such as Figure 1~6 As shown, the embodiment of the present invention is a fully automated assembly equipment for FPC connectors, including a workbench 10, an automatic assembly device 20 arranged on the workbench 10, and an intelligent control system for controlling the automatic assembly device 20. The described The automatic assembly device 20 includes a rubber core feeding station 21 for conveying the rubber core, a terminal sheet assembly station 22, a material shifting station 23, a terminal sheet scrap removal station 24, a terminal sheet material dividing station 25, and a solder sheet assembly Station 26, clamshell assembly station 27, finished product inspection station 28, finished product automatic packaging station 29, the rubber core feeding station 21, terminal piece assembly station 22, material shifting station 23, terminal piece waste removal Station 24, terminal strip material distribution station 25, solder tab assembly station 26, cover assembly sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com