Bubble-propelled microactuator with micro/nano hierarchical porous structure and preparation method thereof

A micro-actuator and porous structure technology, applied in the direction of nanostructure manufacturing, specific nanostructure formation, chemical instruments and methods, etc., can solve the problems of not having a hierarchical porous structure, complex multi-step preparation methods, etc., and achieve simple functional modification Ease of use, high application value, and the effect of increasing the functional surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

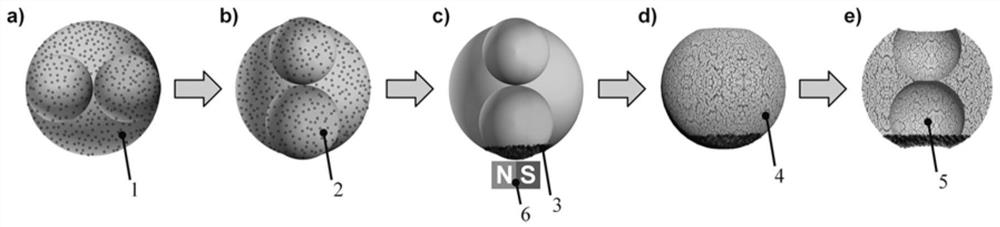

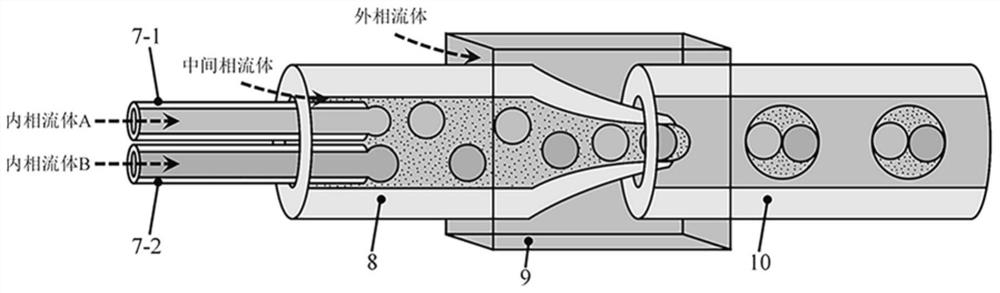

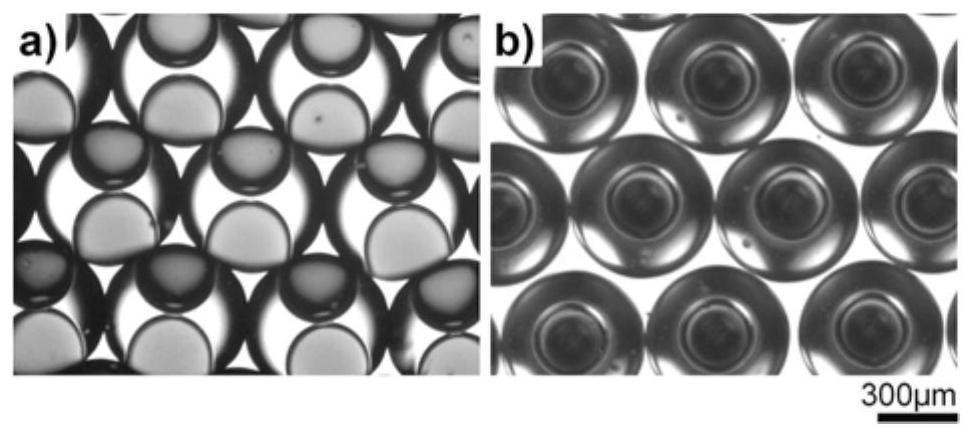

[0067] In this example, a bubble-propelled micro-actuator with a micron / nano hierarchical porous structure was prepared, and the schematic diagram of the preparation process is shown in figure 1 As shown, the steps are as follows:

[0068] (1) Preparation of internal phase, intermediate phase, external phase fluid and collection solution

[0069] Prepare internal phase fluid: Dissolve Pluronic F-127 in deionized water to obtain internal phase fluid A. The mass ratio of water to Pluronic F-127 in internal phase fluid A is 1:0.01; Pluronic F-127 and glycerol Dissolve in deionized water to obtain internal phase fluid B. In internal phase fluid B, the mass ratio of deionized water, Pluronic F-127 and glycerin is 1:0.01:1.

[0070] Preparation of interphase fluid: Mix ETPTA, BB, PGPR, HMPP, and nano-magnetic catalytic particles uniformly to obtain an interphase fluid. In the interphase fluid, the volume ratio of ETPTA to BB is 6:4. Contains 0.2gPGPR, 0.01mL HMPP, 0.005g nano-mag...

Embodiment 2

[0080] In this example, a bubble-propelled micro-actuator with a micron / nano hierarchical porous structure is prepared, and the steps are as follows:

[0081] (1) Preparation of internal phase, intermediate phase, external phase fluid and collection solution

[0082] Prepare internal phase fluid: Dissolve Pluronic F-127 in deionized water to obtain internal phase fluid A. The mass ratio of water to Pluronic F-127 in internal phase fluid A is 1:0.01; Pluronic F-127 and glycerol Dissolve in deionized water to obtain internal phase fluid B. In internal phase fluid B, the mass ratio of deionized water, Pluronic F-127 and glycerin is 1:0.01:1.

[0083] Preparation of interphase fluid: Mix ETPTA, BB, PGPR, HMPP, and nano-magnetic catalytic particles uniformly to obtain an interphase fluid. In the interphase fluid, the volume ratio of ETPTA to BB is 6:4. Contains 0.2gPGPR, 0.01mL HMPP, 0.02g nano-magnetic catalytic particles; the nano-magnetic catalytic particles are Fe 3 o 4 @Ag ...

Embodiment 3

[0092] In this example, the effect of sodium dodecyl sulfate (SDS) concentration on the motion of the micro-actuator provided by the present invention was studied.

[0093] The micro-actuator prepared in Example 1 was added with 30% (v / v) H containing different concentrations of SDS 2 o 2 , observe the movement of the micro-actuator, the results are as follows Figure 10 As shown, the maximum motion speed of the microactuator in the above solution is 255.2 μm s -1 , Figure 11 is the variation curve of the micro-actuator movement rate with the concentration of SDS.

[0094] Add 30% (v / v) H containing different concentrations of SDS to the microdrive prepared in Example 2 2 o 2 , observing the movement of the micro-actuator, the maximum speed of the micro-actuator can reach ~1646.2μm s -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com