Circulation type methane matrix membrane biological membrane reactor and sewage treatment method

A biofilm reactor and matrix membrane technology, which is applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor mass transfer effect of methane and low utilization rate of alkanes , sludge is easy to adhere to and other problems, to achieve the effect of reducing energy consumption, low engineering cost, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described:

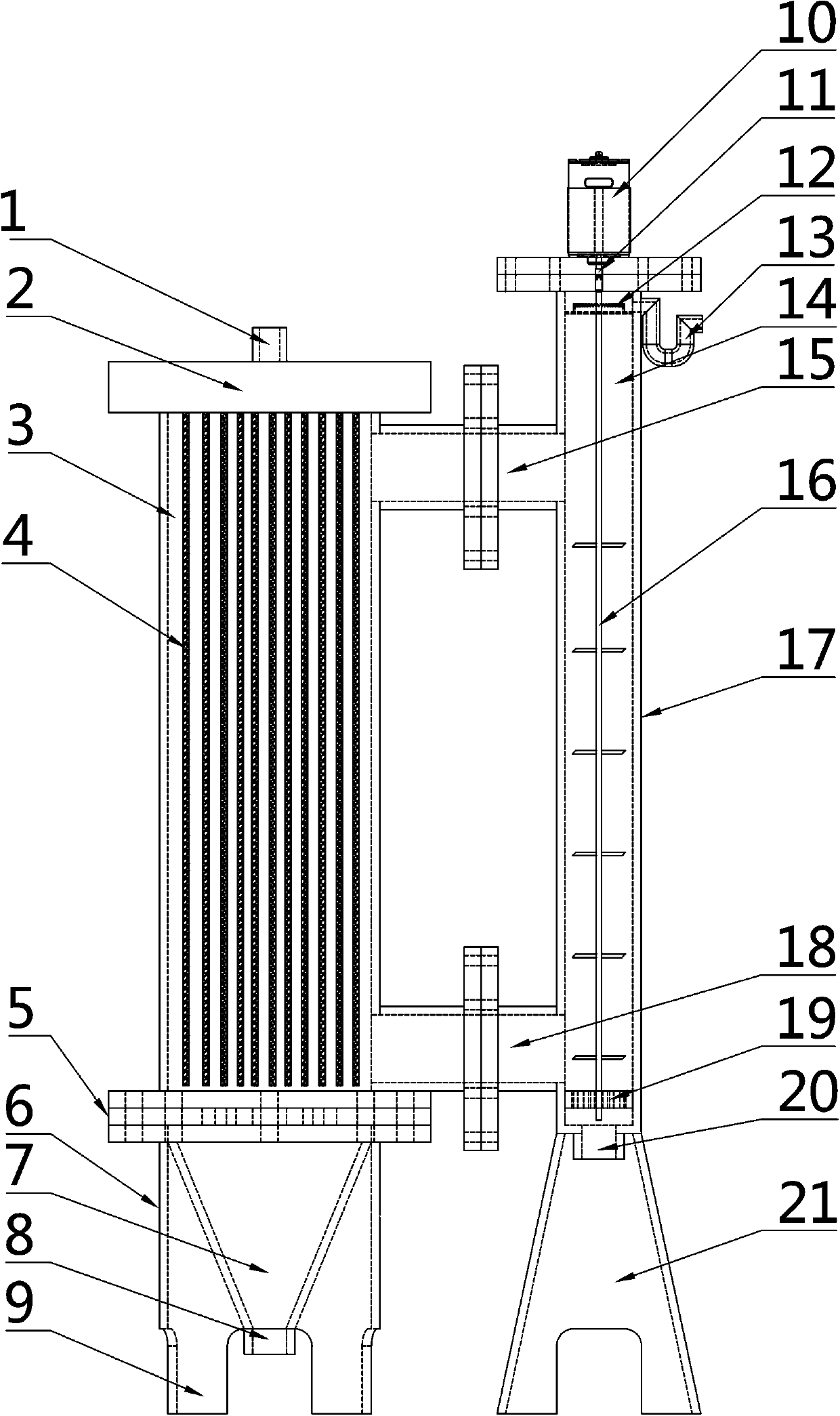

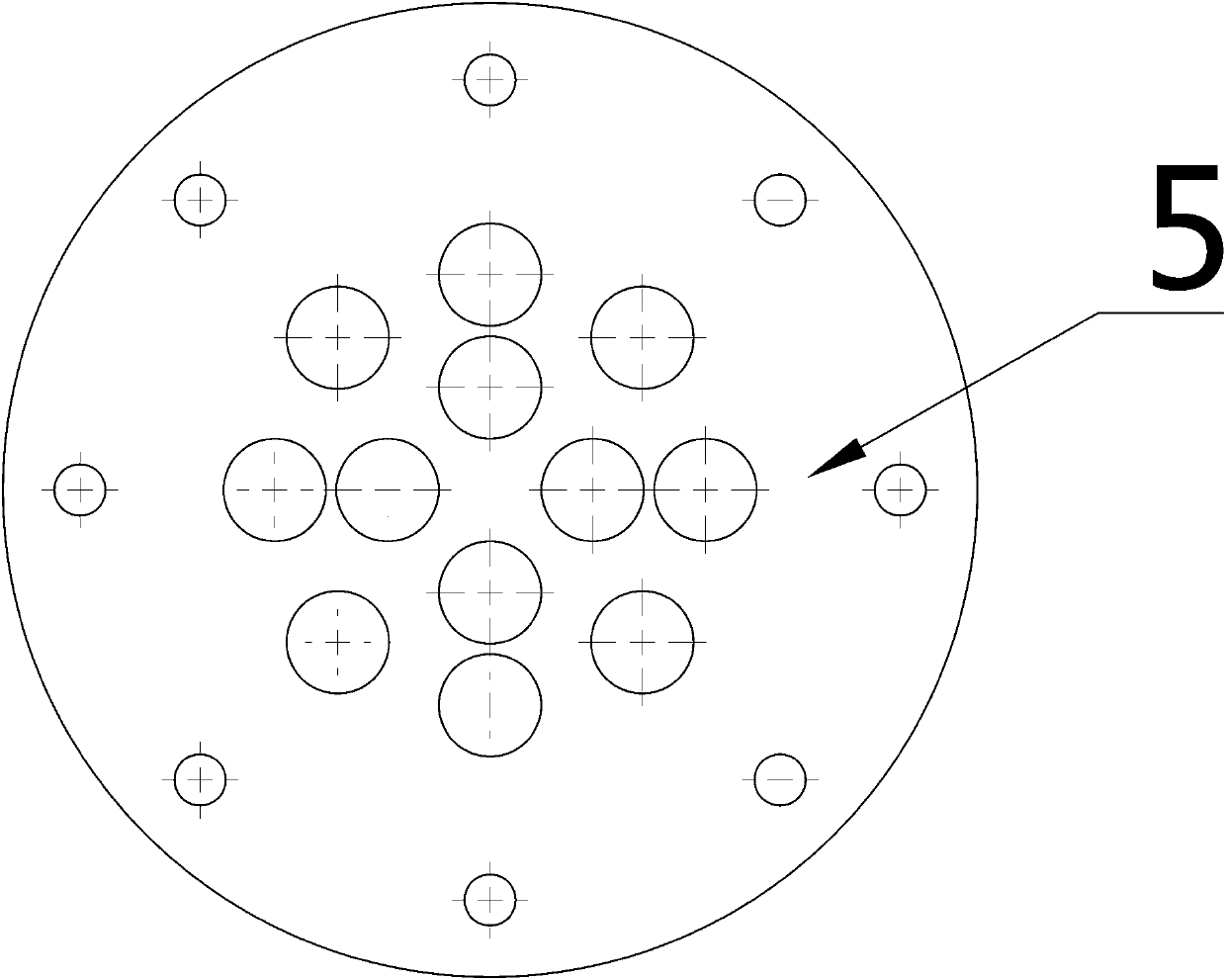

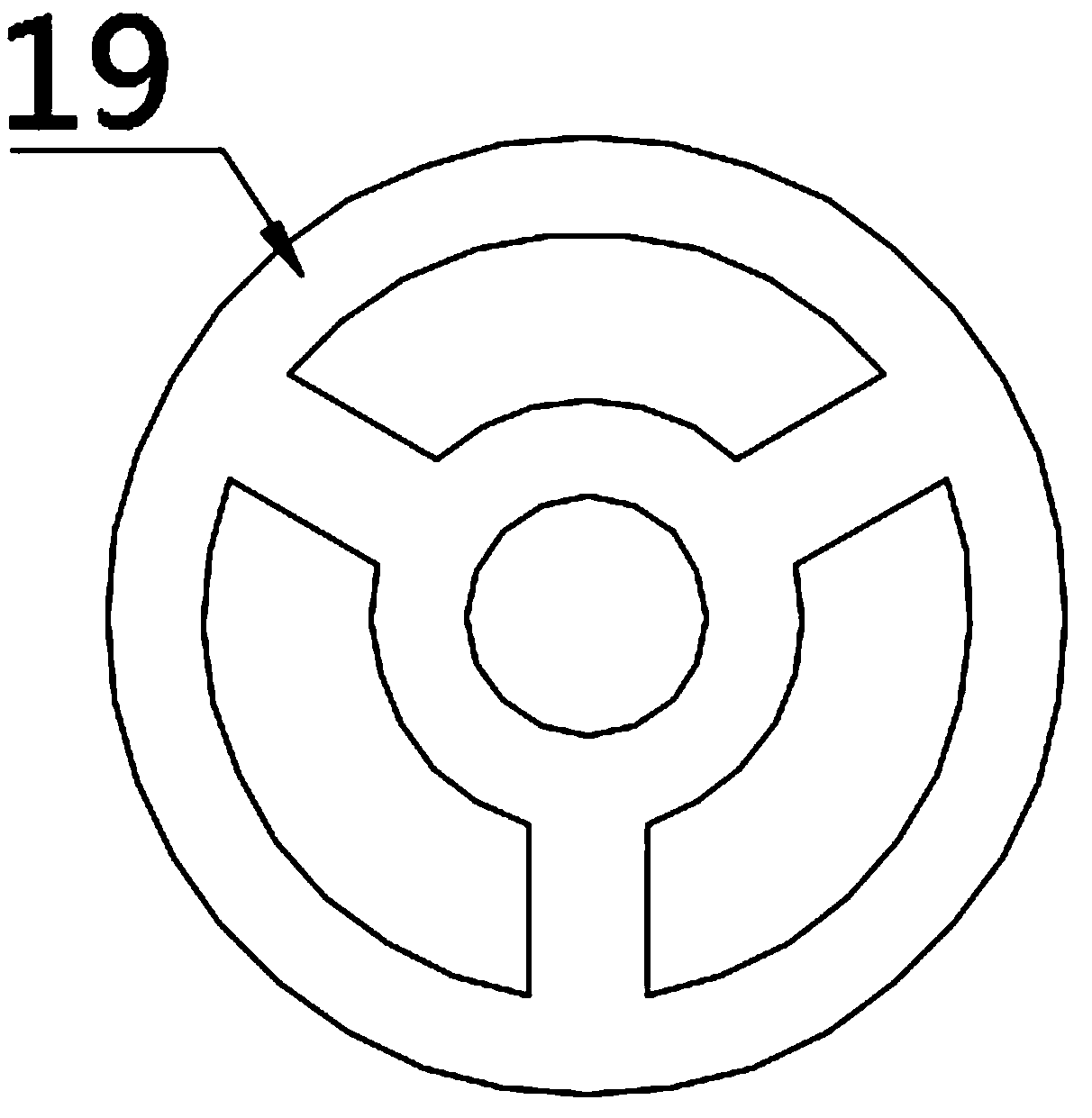

[0038] Such as figure 1 , figure 2 and image 3Shown, a kind of circulation type methane matrix membrane biofilm reactor comprises main reaction zone 3, head 2, hollow fiber membrane 4, sludge zone 6, upper transition pipe 15, lower transition pipe 18, circulation pipe 17, drive Motor 10 and axial-flow stirring paddle 16, the upper end of the main reaction zone 3 is closed by the sealing head 2, and the sealing head 2 is provided with an air inlet pipe 1. Preferably, the hollow fiber membrane 4 has tiny pores and is inserted into the sealing head 2 The bottom is fixed with glue seal, the lower end of the head 2 is connected with the upper part of the main reaction zone 3 by threads, the outer surface of the hollow fiber membrane 4 is attached with denitrifying methane anaerobic oxidation functional microorganisms, and one end of the hollow fiber membrane 4 is sealed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com