Refining method of glycochenodeoxycholic acid sodium

A technology of sodium glycochenodeoxycholate and glycochenodeoxycholic acid, which is applied in the field of refining sodium glycochenodeoxycholate, can solve the problems of low HPLC purity, and achieve process stability, easy control, and process operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

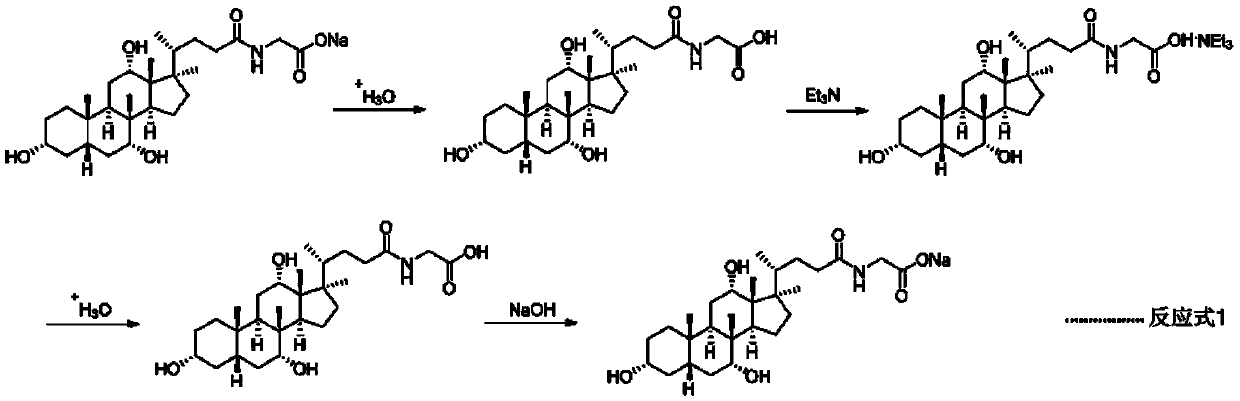

Method used

Image

Examples

Embodiment 1

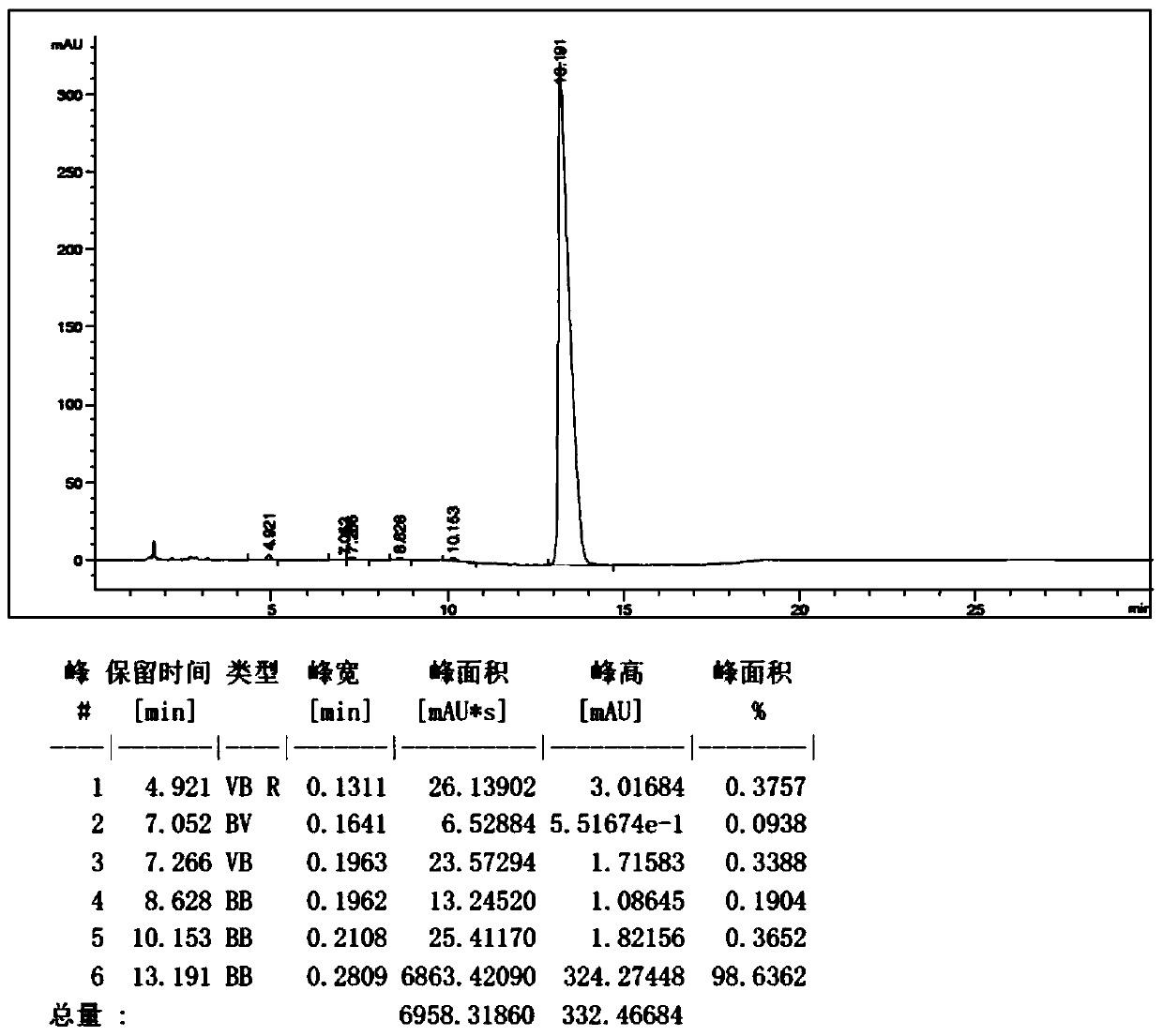

[0039] Example 1 Sodium glycochenodeoxycholate refined

[0040] Such as figure 2 , take 1 kg of commercially available sodium glycochenodeoxycholate, HPLC purity 96.6%, add 6 kg of water and stir to dissolve completely, adjust the pH value to 5.5~6.0 with concentrated hydrochloric acid, and extract three times with ethyl acetate. The pH value of the water phase was adjusted to 1.5-2.0 with concentrated hydrochloric acid, stirred, filtered, the filter cake was rinsed with water, and dried to obtain 918 g of glycochenodeoxycholic acid.

[0041] Glycychenodeoxycholic acid and triethylamine were added to ethyl acetate at a molar ratio of 1:1.2, heated to 80 o C under stirring for 10 hours, cooled and filtered, washed with ethyl acetate, and dried to obtain 1.06 kg of triethylamine salt of glycochenodeoxycholic acid.

[0042] Suspend triethylamine salt of glycochenodeoxycholic acid in acetone and water, adjust the pH value to 1.5~2.0 with concentrated hydrochloric acid, stir, fi...

Embodiment 2

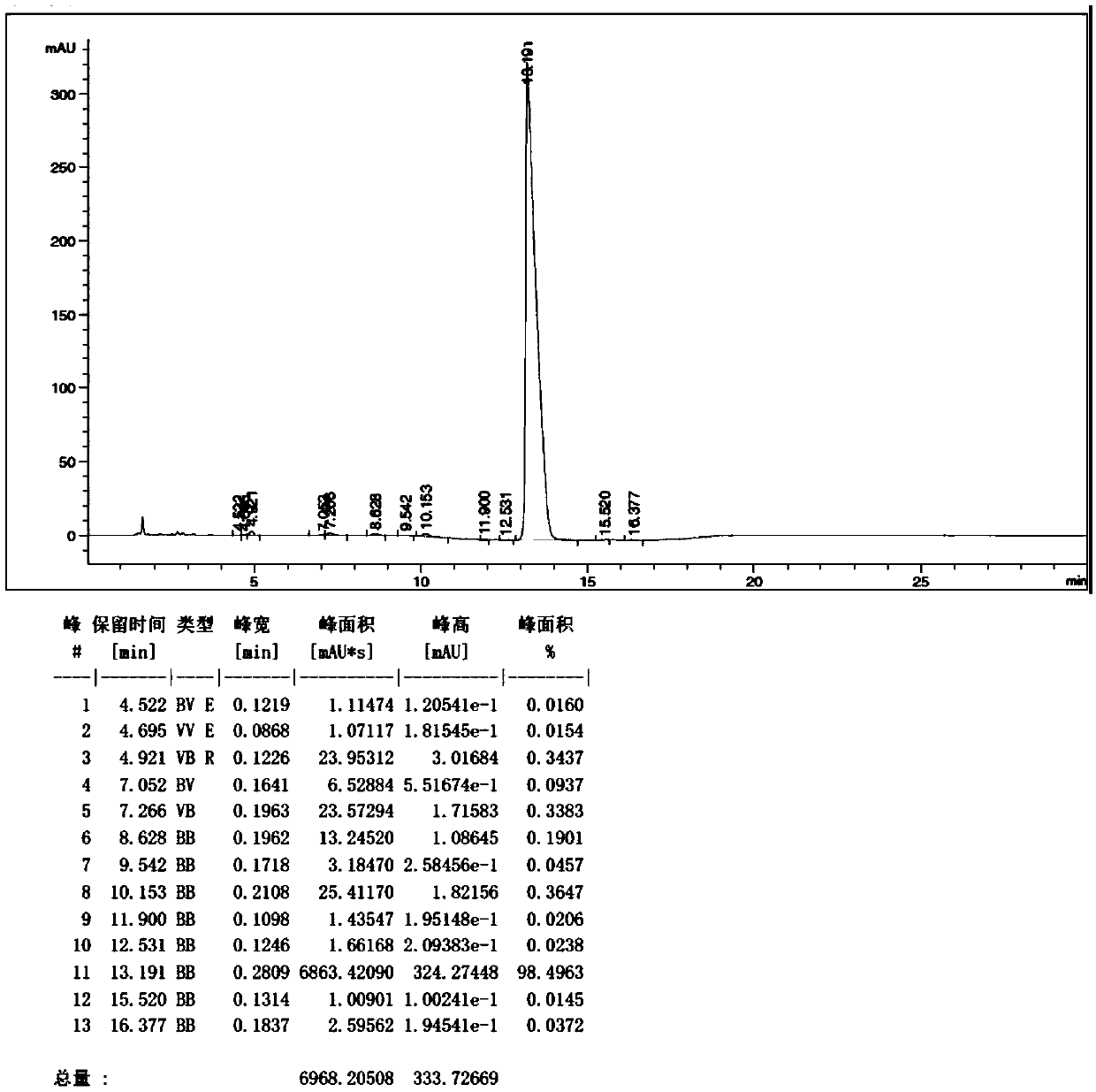

[0044] Example 2 Refining Sodium Glychenodeoxycholate

[0045] Such as image 3 , take 1 kg of commercially available sodium glycochenodeoxycholate, HPLC purity 95.2%, add 6 kg of water and stir to dissolve completely, adjust the pH value to 5.5~6.0 with acetic acid, and extract three times with ethyl acetate. The pH of the aqueous phase was adjusted to 1.5-2.0 with concentrated hydrochloric acid, stirred, filtered, the filter cake was rinsed with water, and dried to obtain 922 g of glycochenodeoxycholic acid.

[0046] Glycychenodeoxycholic acid and triethylamine were added to ethyl acetate at a molar ratio of 1:1.2, heated to 80 o C under stirring for 8 hours, cooled and filtered, washed with ethyl acetate, and dried to obtain 1.04 kg of triethylamine salt of glycochenodeoxycholic acid.

[0047] Dissolve triethylamine salt of glycochenodeoxycholic acid in water, adjust the pH value to 1.5~2.0 with concentrated hydrochloric acid, stir, filter, rinse the filter cake with water,...

Embodiment 3

[0049] Example 3 Refining Sodium Glycychenodeoxycholate

[0050] Such as Figure 4 , take 1 kg of commercially available sodium glycochenodeoxycholate, HPLC purity 97.2%, add 6 kg of water and stir to dissolve completely, adjust the pH value to 5.5~6.0 with concentrated hydrochloric acid, and extract three times with ethyl acetate. The pH of the aqueous phase was adjusted to 1.5-2.0 with concentrated hydrochloric acid, stirred, filtered, the filter cake was rinsed with water, and dried to obtain 932 g of glycochenodeoxycholic acid.

[0051] Glycychenodeoxycholic acid and triethylamine were added into acetone at a molar ratio of 1:1.2, heated to 60 o C under stirring for 12 hours, cooled and filtered, washed with ethyl acetate, and dried to obtain 1.1 kg of triethylamine salt of glycochenodeoxycholic acid.

[0052] Dissolve triethylamine salt of glycochenodeoxycholic acid in water, adjust the pH value to 1.5-2.0 with concentrated hydrochloric acid, stir, filter, rinse the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com