A kind of preparation method based on acetoacetate modified castor oil cured coating

A technology of acetoacetate and tert-butyl acetoacetate is applied in the field of new curing systems to achieve the effects of good sustainability, simple coating curing and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

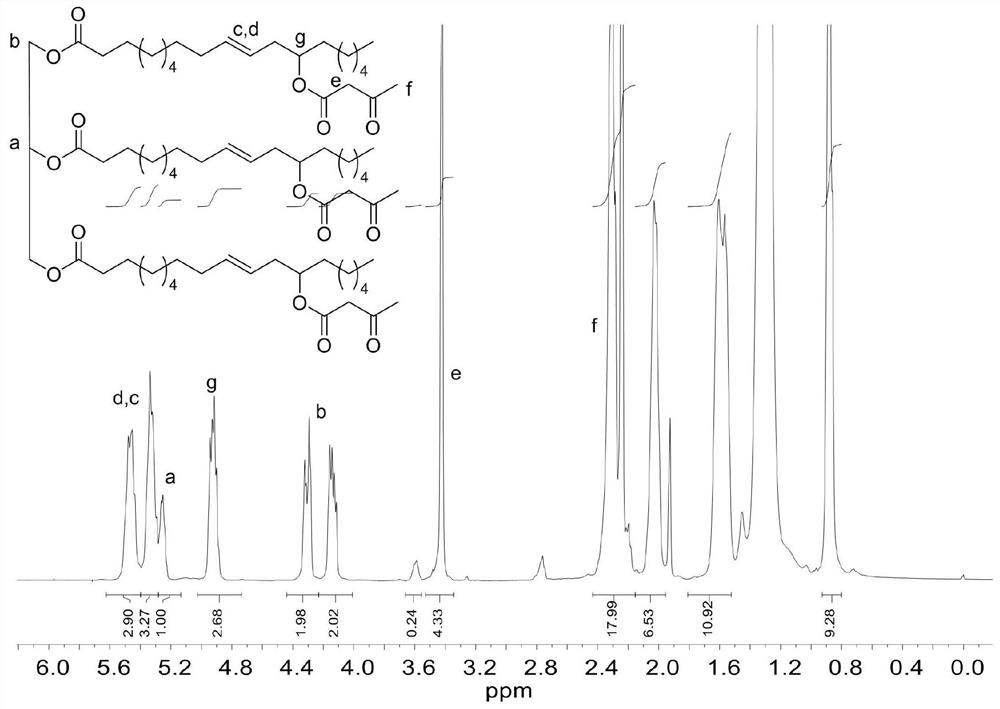

Method used

Image

Examples

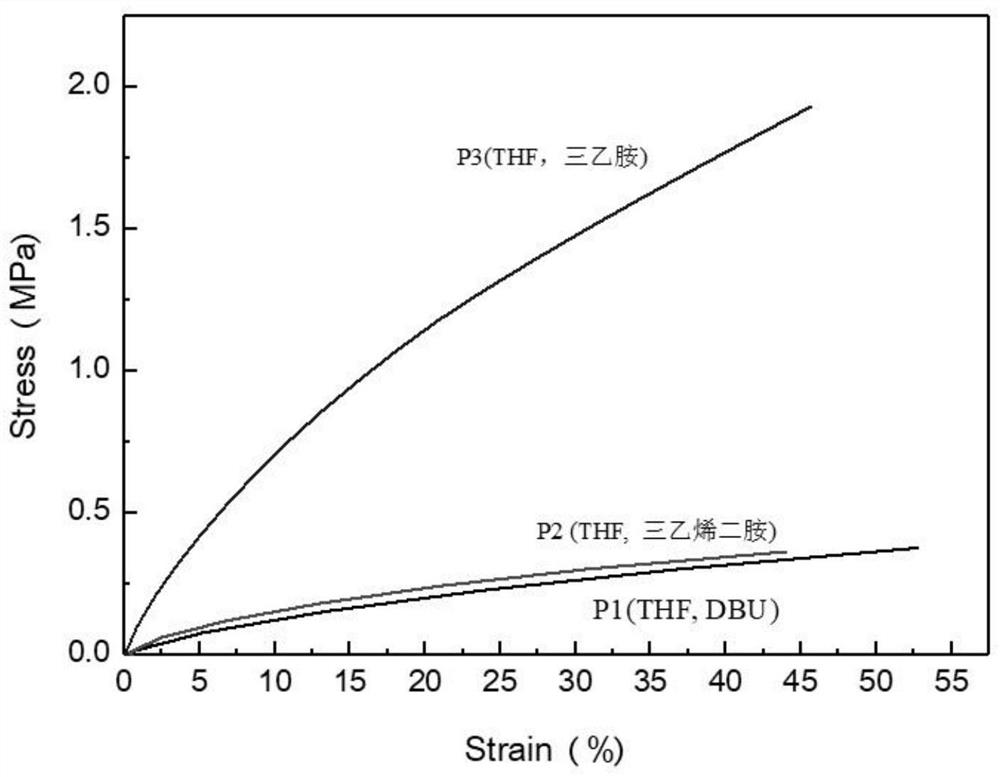

Embodiment 1

[0037] Take a 30*50 weighing bottle and fill it with acylated castor oil (1.5g, 1.265mmol), add a stir bar and 10ml of tetrahydrofuran, put it on an oil bath and stir to completely dissolve the acylated castor oil, then add Bismale imide (0.68g, 1.8975mmol), add triethylamine (60ul, 0.431mmol) with a pipette gun, cover the lid, stir until the solids are all dissolved, pour the system into the mold, seal it with a plastic bag, Place in a fume hood to cure. (Wherein the functional ratio of acylated castor oil and bismaleimide is 1:1, and the quality of catalyst triethylamine is 2% of the total mass of acylated castor oil and bismaleimide).

Embodiment 2

[0039] Take a 30*50 weighing bottle and fill it with acylated castor oil (1.5g, 1.265mmol), add a stir bar and 10ml of tetrahydrofuran, put it on an oil bath and stir to completely dissolve the acylated castor oil, then add Bismale Imide (0.68g, 1.8975mmol), add triethylenediamine (43.37mg, 0.387mmol) with a pipette gun, cover the lid, stir until the solid is completely dissolved, pour the system into a mold, seal it with a plastic bag Live and cure in a fume hood. (wherein the functional ratio of acylated castor oil and bismaleimide is 1:1, and the mass of the catalyst triethylenediamine is 2% of the total mass of acylated castor oil and bismaleimide).

Embodiment 3

[0041] Take a 30*50 weighing bottle and fill it with acylated castor oil (1.5g, 1.265mmol), add a stir bar and 10ml of tetrahydrofuran, put it on an oil bath and stir to completely dissolve the acylated castor oil, then add Bismale Imide (0.68g, 1.8975mmol), add DBU (40.21ul, 0.285mmol) with a pipette gun, cover the lid, stir until the solid is completely dissolved, pour the system into the mold, seal it with a plastic bag, and put Cured in a fume hood. (wherein the functional ratio of acylated castor oil and bismaleimide is 1:1, and the mass of catalyst DBU is 2% of the total mass of acylated castor oil and bismaleimide).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com