Crimp connection type IGBT internal package structure

An internal packaging and crimping technology, which is applied in the direction of semiconductor/solid-state device parts, electrical components, and electrical solid-state devices, can solve the problems of difficult mutual positioning, high chip loss rate, and complicated packaging process, etc., to achieve convenient module Minimized assembly, simplified packaging process, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

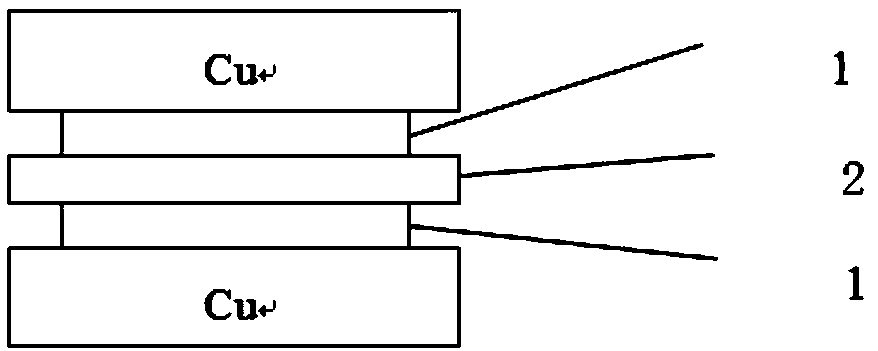

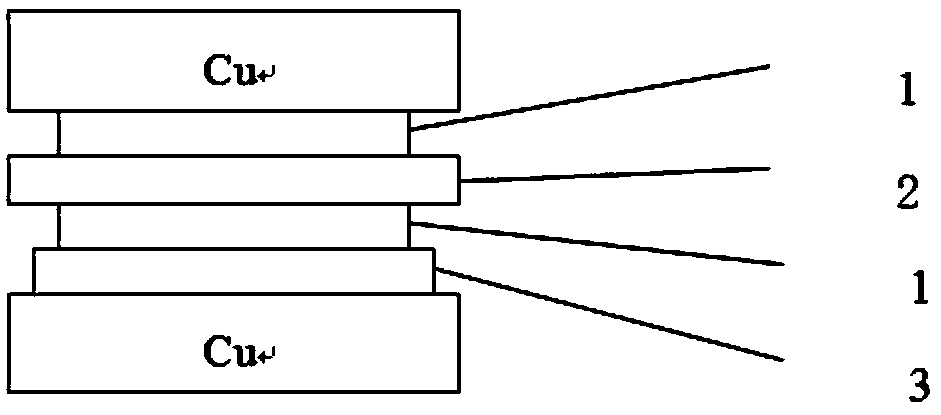

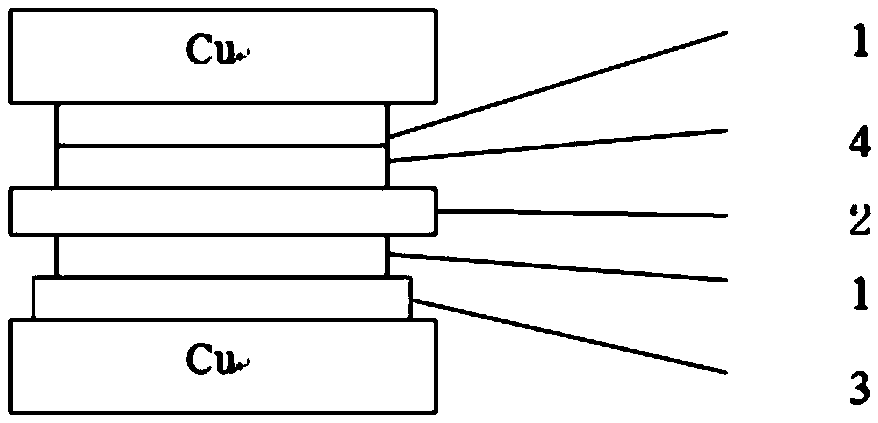

[0028] In order to simplify the packaging process of the ceramic shell press-fit IGBT and realize the development of the press-fit IGBT, the present invention has finally designed a new internal structure of the press-fit IGBT packaged in the ceramic shell through assiduous technical research. like Image 6 As shown, the structure specifically includes the IGBT / FRD chip 2 and the silicon carbide aluminum layer 9, the silicon carbide aluminum layer 9 is located on the upper and lower sides of the IGBT / FRD chip 2, and the IGBT / FRD chip 2 and the silicon carbide aluminum layer A solder layer 10 is provided between 9, and a metal layer 11 is provided on the upper and lower surfaces of the IGBT / FRD chip 2.

[0029] The present invention has obtained through several tests that the material of the metal layer 11 is preferably an Al / Ti / Ni / Ag four-layer integrated metal layer, and the thickness is preferably 2um-5um. Al / Ti / Ni / Ag four-layer integrated metal layer is prepared by traditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com