Method for constructing single-site electrocatalyst by metal phthalocyanine molecular precursor and application

An electrocatalyst and metal phthalocyanine technology, applied in the field of electrocatalysis, can solve the problems of low catalytic activity, poor stability, low metal loading per site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

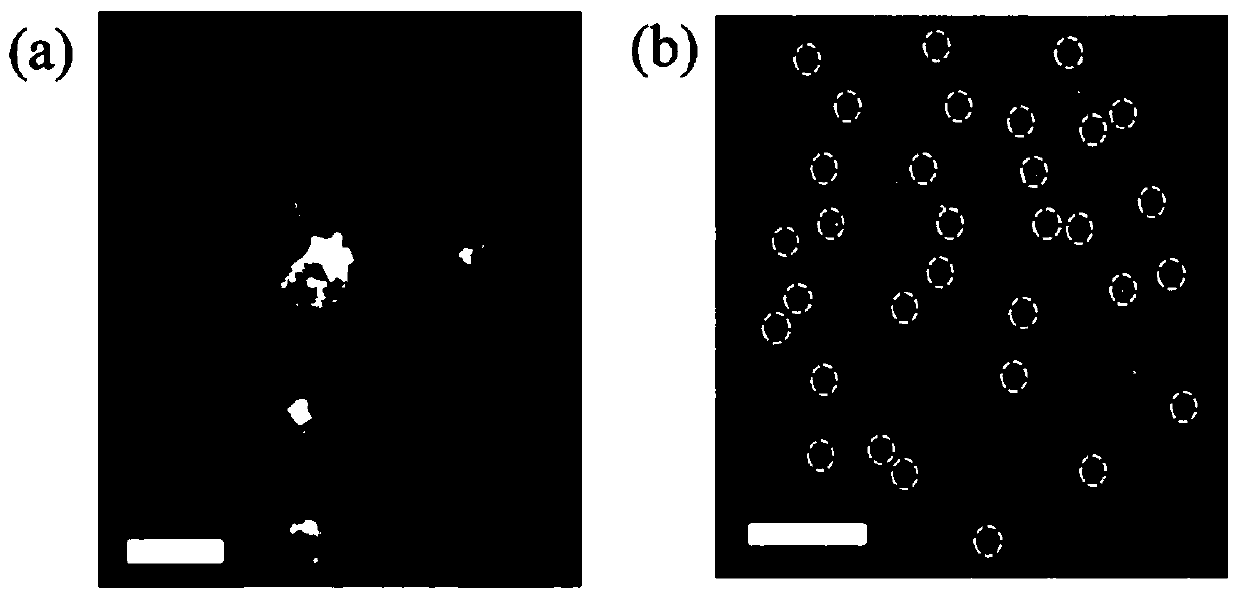

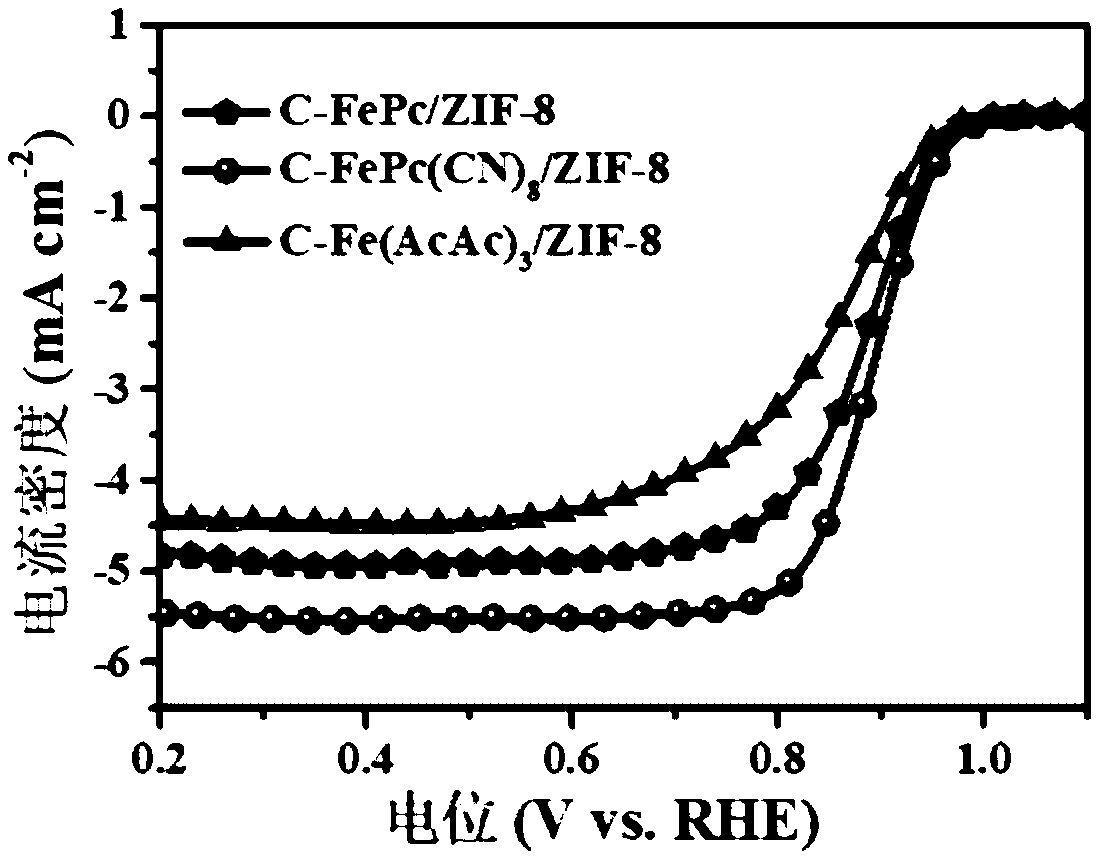

[0073] According to the molar ratio of 1:4, zinc nitrate (6 mmol) and 2-methylimidazole (24 mmol) were respectively weighed and dissolved in 75 mL of anhydrous methanol under the assistance of ultrasound. Then 72.4 mg of iron phthalocyanine was weighed and dissolved in 10 mL of N,N-dimethylformamide solution under ultrasonication. The 2-methylimidazole solution was added to the zinc nitrate solution. Then, the iron phthalocyanine solution was slowly added dropwise into the aforementioned mixed solution, and stirred at room temperature for 18 h under the action of magnetic stirring. Centrifuge the obtained catalyst precursor under high-speed centrifugation, wash and centrifuge three times with N,N-dimethylformamide and methanol respectively, and freeze the above solid in liquid nitrogen, and then freeze-dry it in a freeze dryer for 24 hours . Finally, the dried solid powder was placed in a tube furnace, and under the protection of argon, the temperature was raised to 1000° C....

Embodiment 2

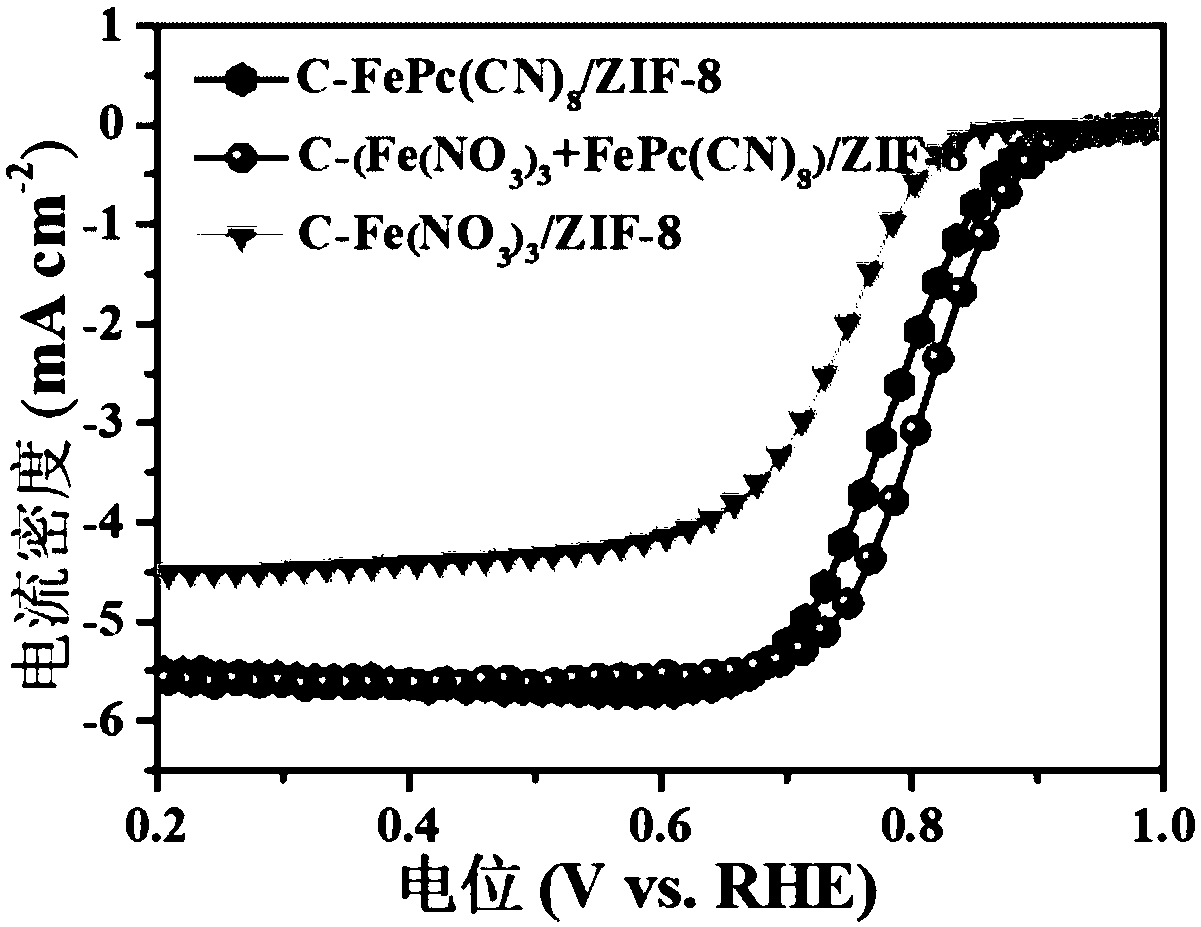

[0079]According to the molar ratio of 1:4, zinc nitrate (6 mmol) and 2-methylimidazole (24 mmol) were respectively weighed and dissolved in 75 mL of anhydrous methanol under the assistance of ultrasound. Then weigh 72.4 mg of octacyanoiron phthalocyanine and dissolve it in 10 mL of N,N-dimethylformamide solution under the action of ultrasound. The 2-methylimidazole solution was added to the zinc nitrate solution. Then, the cyanoiron phthalocyanine solution was slowly added dropwise to the aforementioned mixed solution, and stirred at room temperature for 18 h under the action of magnetic stirring. Centrifuge the obtained catalyst precursor under high-speed centrifugation, wash and centrifuge three times with N,N-dimethylformamide and methanol respectively, and freeze the above solid in liquid nitrogen, and then freeze-dry it in a freeze dryer for 24 hours . Finally, the dried solid powder was placed in a tube furnace, and under the protection of argon, the temperature was ra...

Embodiment 3

[0086] According to the molar ratio of 1:4, zinc nitrate (5.88mmol), iron nitrate (0.12mmol) and 2-methylimidazole (24mmol) were weighed respectively, and dissolved in 75mL of anhydrous methanol under the assistance of ultrasound. Then weigh 72.4 mg of octacyanoiron phthalocyanine and dissolve it in 10 mL of N,N-dimethylformamide solution under the action of ultrasound. Add the 2-methylimidazole solution to the mixed solution of zinc nitrate and ferric nitrate. Then, the cyanoiron phthalocyanine solution was slowly added dropwise into the mixed solution of 2-methylimidazole, zinc nitrate and ferric nitrate, and stirred at room temperature for 18 h under the action of magnetic stirring. Centrifuge the obtained catalyst precursor under high-speed centrifugation, wash and centrifuge three times with N,N-dimethylformamide and methanol respectively, and freeze the above solid in liquid nitrogen, and then freeze-dry it in a freeze dryer for 24 hours . Finally, the dried solid powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com