Metal air battery and preparation method thereof

A metal-air battery and air electrode technology, which is applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of slow reaction rate and energy conversion efficiency, and achieve low cost, long service life and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

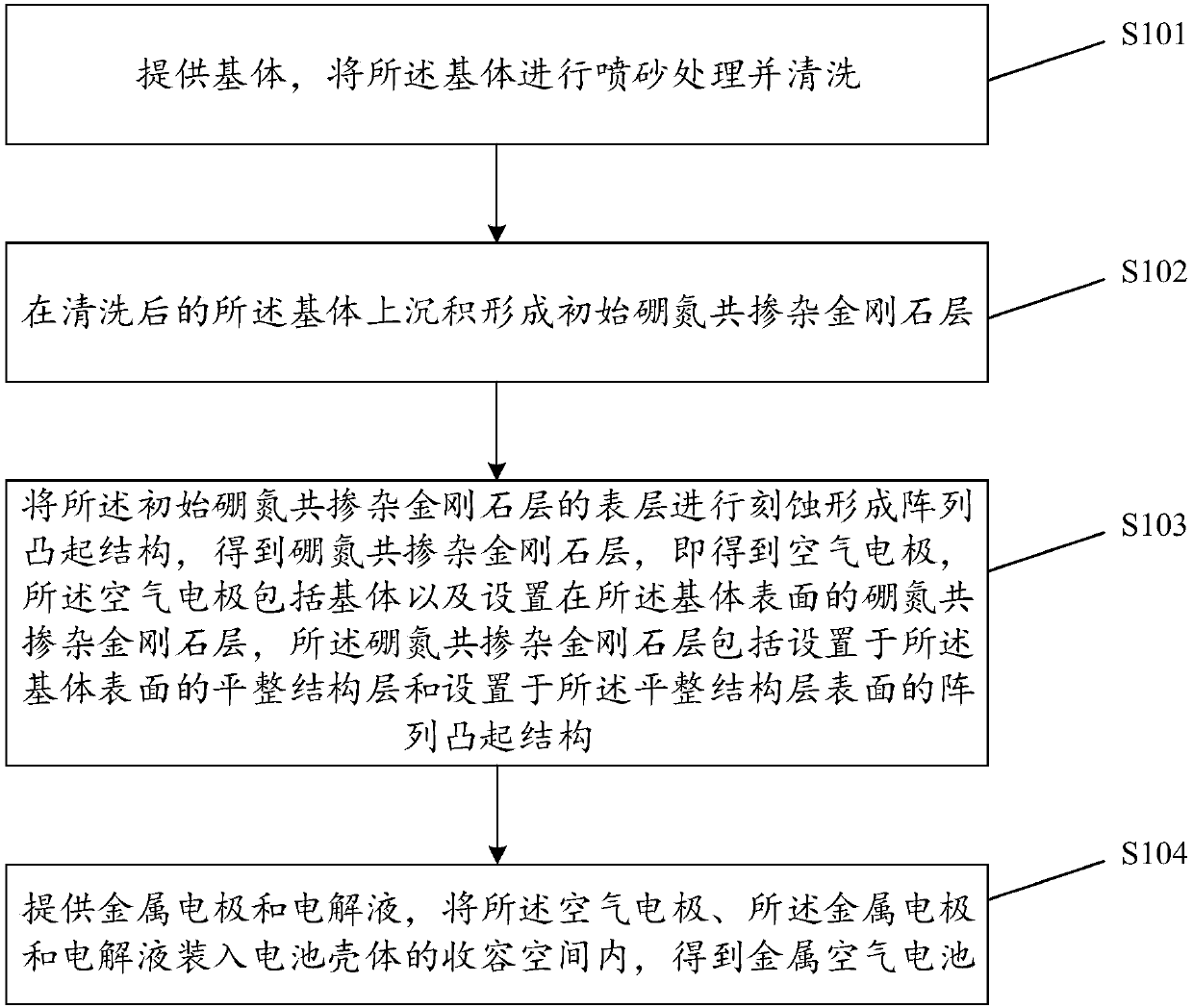

[0029] see figure 1 , a method for preparing a metal-air battery provided by the implementation of the present invention, comprising:

[0030] Step S101 : providing a substrate, sandblasting and cleaning the substrate.

[0031] In step S101, please refer to figure 2 , the material of the substrate 10 includes one or more of titanium, tantalum, niobium, molybdenum, chromium, silicon, graphite, carbon fiber and cemented carbide. The cleaning includes pickling or alkaline cleaning. The specific operation of cleaning is as follows: heat the substrate 10 in an acidic solution or an alkaline solution to 80°C-100°C, and soak for 10min-30min. Optionally, when the cleaning is pickling, the pickling solution includes sulfuric acid and hydrogen peroxide, wherein the volume ratio of sulfuric acid and hydrogen peroxide is 1:10-15. Optionally, when the cleaning is alkaline cleaning, the alkaline solution of alkaline cleaning includes hydrogen peroxide, ammonium hydroxide and water, whe...

Embodiment 1

[0043] A method for preparing a metal-air battery, comprising the steps of:

[0044] Step 1: Take the niobium substrate, and after blasting the niobium substrate, ultrasonically clean the niobium substrate in acetone and alcohol for 10 minutes respectively. Then place the niobium substrate in an acidic solution of sulfuric acid and hydrogen peroxide with a volume ratio of 1:15, heat it to 100°C, and soak for 30 minutes. Remove surface oxides and cause certain defects for subsequent deposition, and then use deionized water to ultrasonically clean for 10 minutes. Subsequently, the acid-washed niobium matrix was placed in nano-diamond powder suspension and ultrasonically treated for 1 hour.

[0045] Step 2: Deposit a boron-nitrogen co-doped diamond layer on the cleaned niobium substrate by hot wire chemical vapor deposition. During the preparation process, the gases introduced include nitrogen, methane, trimethylborane and hydrogen, nitrogen The flow rate was 24 sccm, the flow ...

Embodiment 2

[0049] A method for preparing a metal-air battery, comprising the steps of:

[0050] Step 1: Take the titanium substrate, and after sandblasting the titanium substrate, ultrasonically clean the titanium substrate in acetone and alcohol for 10 minutes respectively. Then place the titanium substrate in an alkaline solution of hydrogen peroxide, ammonium hydroxide and water at a volume ratio of 1:1:5, heat it to 80°C, and soak for 30 minutes. Remove surface oxides and cause certain defects for subsequent deposition, and then use deionized water to ultrasonically clean for 10 minutes. Subsequently, the acid-washed titanium substrate was placed in the suspension of nano-diamond powder for ultrasonic treatment for 2 hours.

[0051] Step 2: Deposit a boron-nitrogen co-doped diamond layer on the cleaned titanium substrate by hot wire chemical vapor deposition. During the preparation process, the gases introduced include nitrogen, methane, trimethylborane and hydrogen, nitrogen The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com