Novel adjustable terahertz metamaterial absorbing structure

A metamaterial and terahertz technology, applied in antennas, electrical components, etc., can solve the problems of inflexible adjustment and inconvenient preparation of metamaterials, and achieve the effect of uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Generally speaking, the present invention presents a structure combining a new type of integrated air pressure modulation method and a metamaterial absorber. The realization scheme is to change the geometric parameters of the metamaterial structure by changing the pressure in the cavity, and then realize the absorption of the incident terahertz wave. rate modulation.

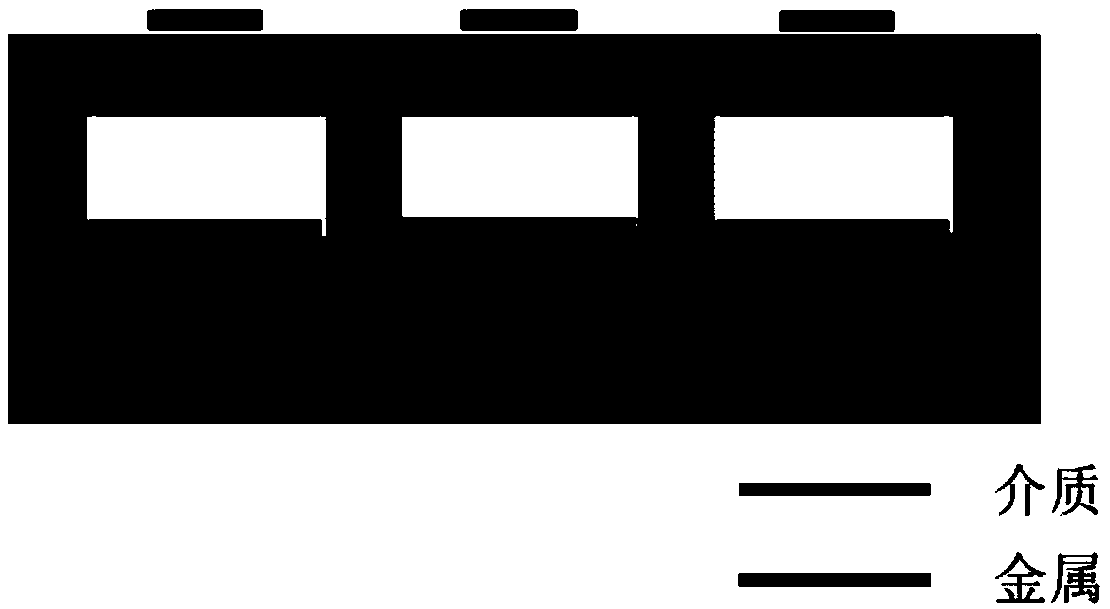

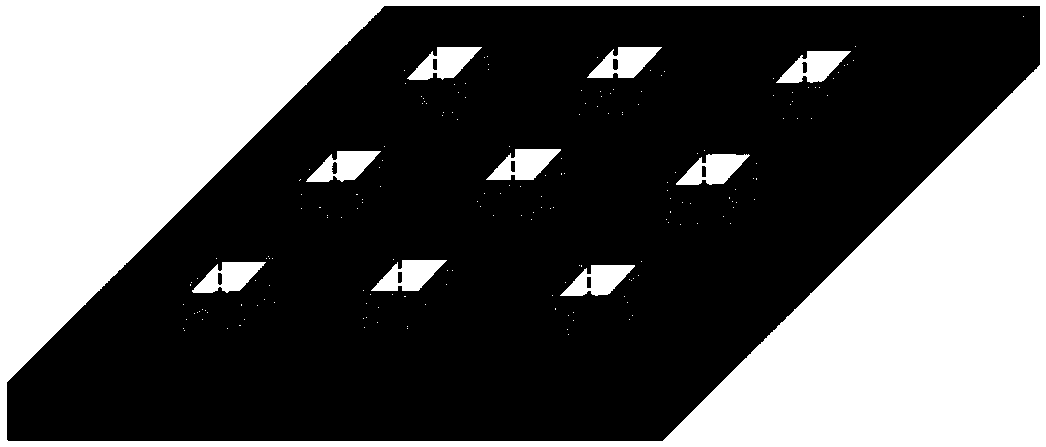

[0038] The structure can be divided into two parts. Such as figure 1 As shown, the upper part is a dielectric thin film and a metal periodic array structure. The lower part is to use the medium as the substrate, and use related processes to prepare a periodic array of square holes with the same specifications on the surface of the medium substrate, and lay a metal layer on the bottom of the square holes, and these square hole structures are consistent with the two-dimensional metal layer structure on the top of the metamaterial. Corresponding to the location, the specific structure is as follows figur...

example 2

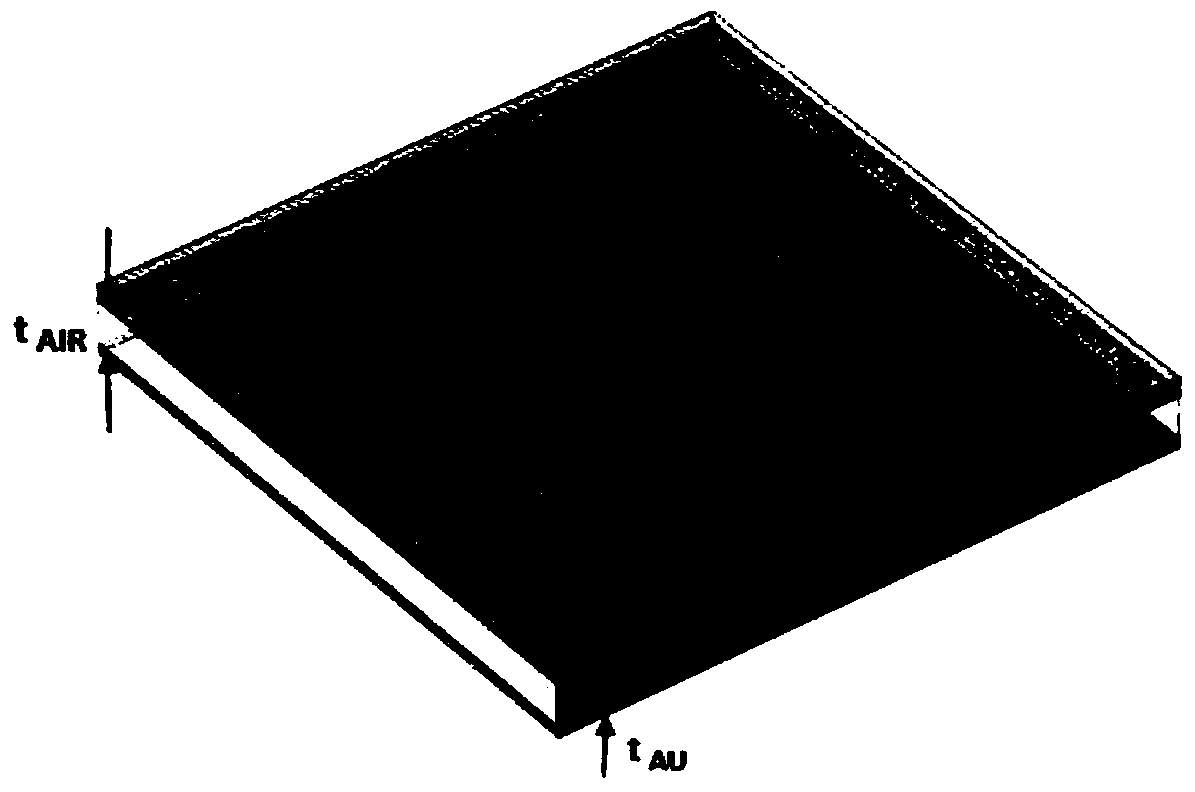

[0043] The cell structure of Example 2 is as Image 6 shown. The metal array is above the dielectric film, the outer layer is a metal frame with gaps, the inner layer is an I-shaped structure, and the thickness of the air cavity is t AIR =2um, bottom metal thickness t AU = 0.85um. In this example, the material of the dielectric film is PDMS, and the thickness t PDMS =2um, relative permittivity is 2.75, loss tangent is 0.05; metal material is copper, thickness t CU =0.85um, the conductivity is 5.81e7S / m. The specific parameters of the structure are as Figure 7 As shown, the period length of the structure is L=66.7um, the metal array square side length L1=53.3um, the line width w=5um, the spacing d=5.4um, and the slit width g=3.4um.

[0044] During modulation, when the pressure of 20KPa and 40KPa is added to the air cavity, the final simulation results are as follows Figure 8 shown. It can be seen that when the PDMS film and the metal array are deformed upward due to t...

example 3

[0046] The unit structure of Example 3 is as Figure 9 shown. The metal array of this structure is under the dielectric film and is composed of two nested square frames with slits inside the air cavity. The cavity thickness of the air cavity is t AIR =3um, bottom metal thickness t AU = 0.85um. In this example, the material of the dielectric film is PDMS, the thickness t PDMS =2um; the material of the metal is gold, and the thickness is t AU = 0.85um. The specific parameters of the structure are as Figure 10 As shown, the period length of the structure is L=66.7um, the metal array square side length L1=53.3um, the line width w=5um, the spacing d=5.4um, and the slit width g=3.4um.

[0047] When the reverse 4KPa and 8KPa pressures are added to the air cavity, the final simulation results are as follows Figure 11 shown. The dielectric film and metal array are deformed downward due to the downward pressure. For the two absorption peaks in this structure, when the struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com