Inflated fermented soymilk beverage and preparation method thereof

A soy milk and beverage technology, applied in the field of beverage processing, can solve problems such as unacceptable, residual beany smell, protein precipitation, etc., and achieve good stability, refreshing taste, and the effect of regulating the balance of intestinal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

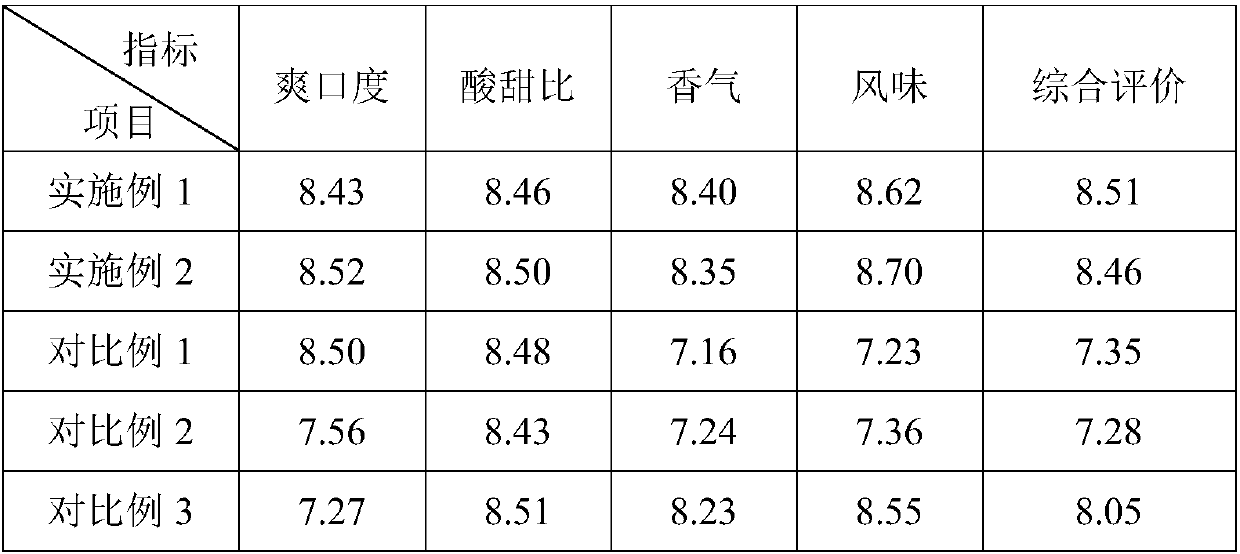

Examples

Embodiment 1

[0027] 1. Raw material formula (measured in 1000g)

[0028] Soy flour (38% protein): 29.9g

[0029] Glucose: 10.6g

[0030] White sugar: 60g

[0031] High fructose syrup: 30g

[0032] Condensed milk: 15g

[0033] Concentrated white grape juice: 10g

[0034] Monoglyceride: 1g

[0035] Polyglycerol ester: 0.4g

[0036] Pectin: 3g

[0037] Soy polysaccharide: 4g

[0038] Lactobacillus casei: 0.013g

[0039] Lactobacillus plantarum: 0.013g

[0040] Citric acid 2.0-2.5g

[0041] Purified water up to: 1000g

[0042] Two, make the aerated fermented soybean milk beverage in the present embodiment according to the following method

[0043] 1. Production of fermented soybean milk

[0044] (1) Add ingredient RO water into the ingredient tank, heat to 45°C-50°C, dry mix soybean powder and glucose, add it to the ingredient tank and stir for 15-20min, finish the ingredient, and let it stand for hydration for 30-40min;

[0045] (2) Homogenize the reduced soybean milk at 30 / 150b...

Embodiment 2

[0060] 1. Raw material formula (measured in 1000g)

[0061] Soy flour (38% protein): 29.9g

[0062] Crystalline fructose: 12g

[0063] White sugar: 60g

[0064] High fructose syrup: 30g

[0065] Condensed milk: 15g

[0066] Concentrated apple juice: 15g

[0067] Monoglyceride: 1g

[0068] Polyglycerol ester: 0.6g

[0069] Pectin: 4g

[0070] Soy polysaccharide: 3g

[0071] Lactobacillus casei: 0.013g

[0072] Lactobacillus plantarum: 0.013g

[0073] Citric acid 2.0-2.5g

[0074] Purified water up to: 1000g

[0075] Two, make the aerated fermented soybean milk beverage in the present embodiment according to the following method

[0076] 1. Production of fermented soybean milk

[0077] (1) Add RO water into the batching tank, heat it to 45°C-50°C, dry mix soybean powder and crystalline fructose, add it to the batching tank and stir for 15-20min, finish the batching, and let stand for 30-40min for hydration ;

[0078] (2) Homogenize the reduced soybean milk at 30 / 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com