Low-silicon-aluminum-ratio ZSM-12 type zeolite molecular sieve synthesis method

A technology of ZSM-12 and zeolite molecular sieve, which is applied in the direction of ZSM-12 crystalline aluminosilicate zeolite and crystalline aluminosilicate zeolite, can solve the problems of low feasibility and high impurities, and achieve high feasibility and high purity , the effect of low silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

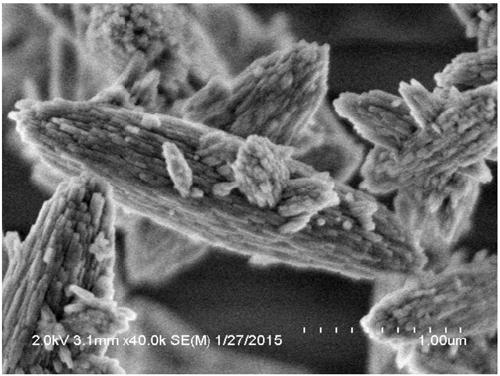

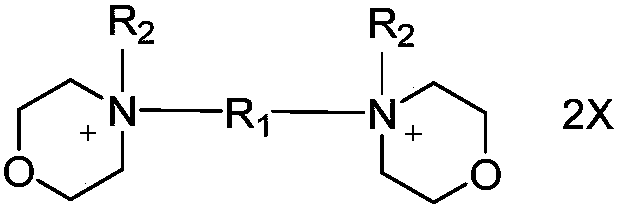

[0024] Mix 40% silica sol, sodium metaaluminate, templating agent Q1, and water in a molar ratio of 1SiO 2 :0.02Al(OH) 3 :0.2 Templating agent Q1:50H 2 O was mixed evenly, and the above mixture was moved into a reaction kettle and crystallized at 170°C for 120 hours. After the reaction was completed, after washing and drying, it was identified as a molecular sieve with a ZSM-12 structure by XRD. The related structure of template agent Q1 is shown in Table 1.

Embodiment 2

[0026] Mix 40% silica sol, alumina, templating agent Q2, and water in a molar ratio of 1SiO 2 :0.04Al(OH) 3 :0.5 Templating agent Q2:100H 2 O was mixed evenly, and the above mixture was moved into a reaction kettle and crystallized at 150°C for 100 hours. After the reaction was completed, after washing and drying, it was identified as a molecular sieve with a ZSM-12 structure by XRD. The related structure of template agent Q2 is shown in Table 1.

Embodiment 3

[0028] Mix 40% silica sol, alumina, templating agent Q2, and water in a molar ratio of 1SiO 2 :0.05Al(OH) 3 :0.25 template Q2:100H 2 O was mixed evenly, and the above mixture was moved into a reaction kettle and crystallized at 150°C for 120 hours. After the reaction was completed, after washing and drying, it was identified as a molecular sieve with a ZSM-12 structure by XRD. The related structure of template agent Q2 is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com