Energy absorbing method based on hybrid dynamic polymer composition

A technology of polymer and composition, applied in the field of energy absorption of hybrid dynamic polymer composition, can solve the problems of limited shock absorption, impact energy dissipation, human injury, etc., and achieve strong dynamics, unique low temperature performance, Effect of Sensitive Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0166] In the preparation process of dynamic polymers, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0167] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it shape and become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0168] Wherein, the physical foaming method is to use physical principles to realize the foaming of the polymer during the preparation of the dynamic polymer, which includes but not limited to the following methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty material under pressure, and then ...

Embodiment 1

[0223]

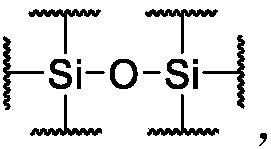

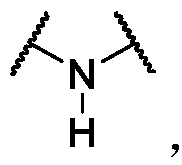

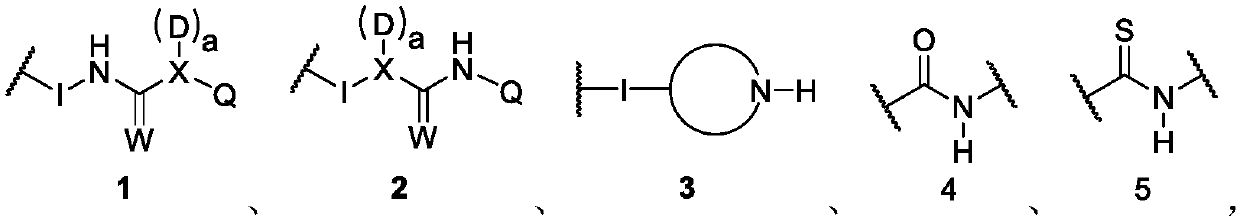

[0224] Mix 1,3,5,7-tetravinyl-1,3,5,7-tetramethylcyclotetrasiloxane and 1,3,5,7-tetramethylcyclotetrasiloxane in a molar ratio of 1 The ratio of : 1 was reacted under the catalysis of chloroplatinic acid, and compound 1 was obtained after sufficient reaction; the ratio of compound 1 and 1,3,5,7-tetramethylcyclotetrasiloxane was 1: 2 in Tetramethylammonium hydroxide pentahydrate and Pt are co-catalyzed by ring-opening polymerization, and 0.5 mg of BHT antioxidant is added to the system, and a transparent polysiloxane material is obtained after 4 hours. Make it into a dumbbell-shaped sample with a size of 80.0×10.0×2.0mm, and use a tensile testing machine to perform a tensile test. The tensile rate is 10mm / min. The measured tensile strength of the sample is 1.54±0.25MPa, and the elongation at break The rate is 436.27±53.78%; stress is applied to the section after cutting it (the section can be slightly wetted during this process), and the section can be rebonded afte...

Embodiment 2

[0226] Add a certain amount of deionized water, concentrated hydrochloric acid with a concentration of 37%, ethanol and hexamethyldisiloxane in sequence in the reactor, stir and heat up to 35°C; then, the sodium silicate solution is stirred rapidly Then, add 3-aminopropyl-methyl-diethoxysiloxane, and stir the reaction at 50-60°C until the solution is separated and a white viscous product is formed Then, let it stand for 2 hours, remove the dilute hydrochloric acid ethanol solution in the upper layer, wash the resin product in the lower layer with water until neutral; finally add a certain amount of toluene for extraction, and then undergo vacuum distillation to obtain the organic silicon with amino group in the side group resin. The obtained product was reacted with ethyl isocyanate in molar ratio at 80°C for 2 hours, and the product was dehydrated with lithium hydroxide to obtain a silicon alkoxide-terminated modified silicone resin gel. The obtained The polymer material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com