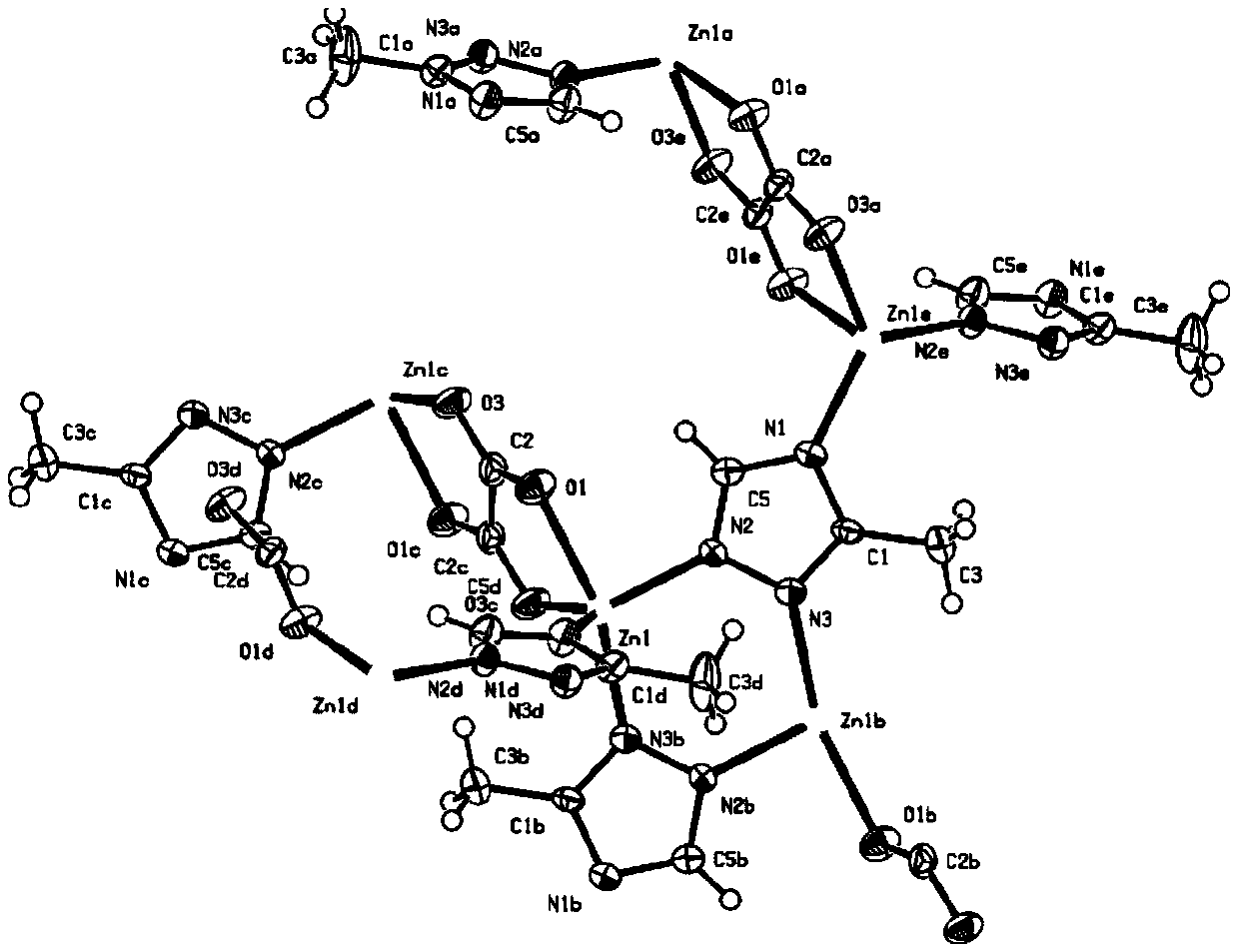

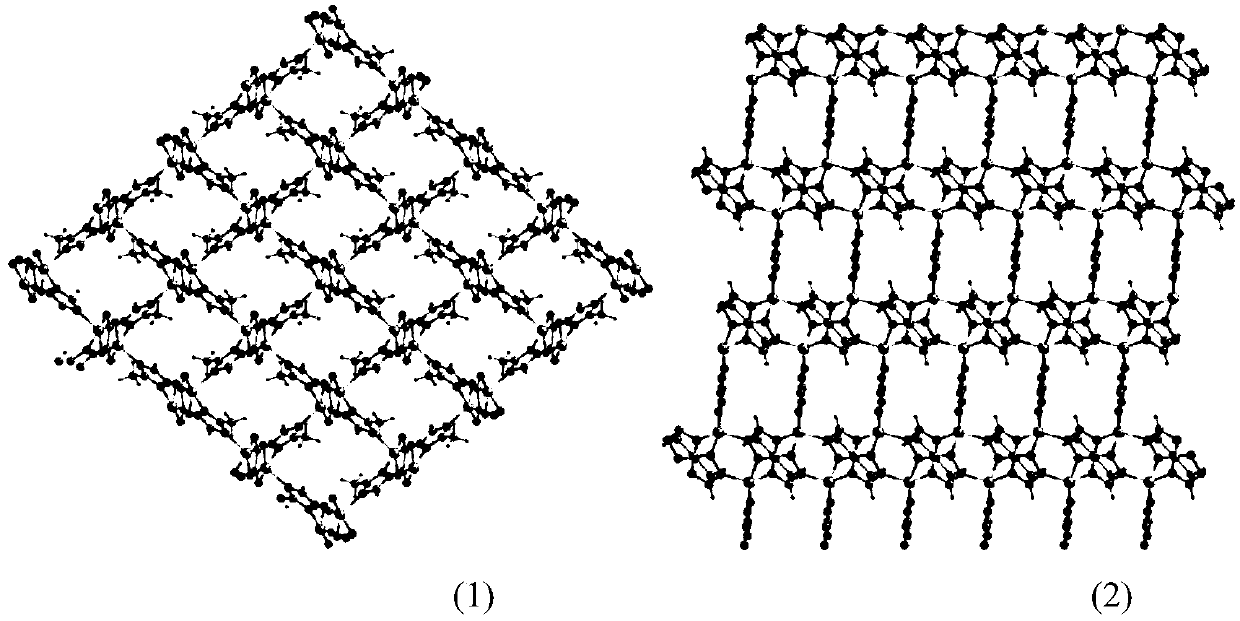

Ultramicropore metallic organic framework material Zn(ox)0.5(mtz) as well as preparation method and adsorption separation application thereof

A metal-organic framework and ultra-microporous technology, which is applied in the field of chemical adsorption materials and chemical separation, can solve the problems of poor selectivity and achieve high selectivity, simple preparation method, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

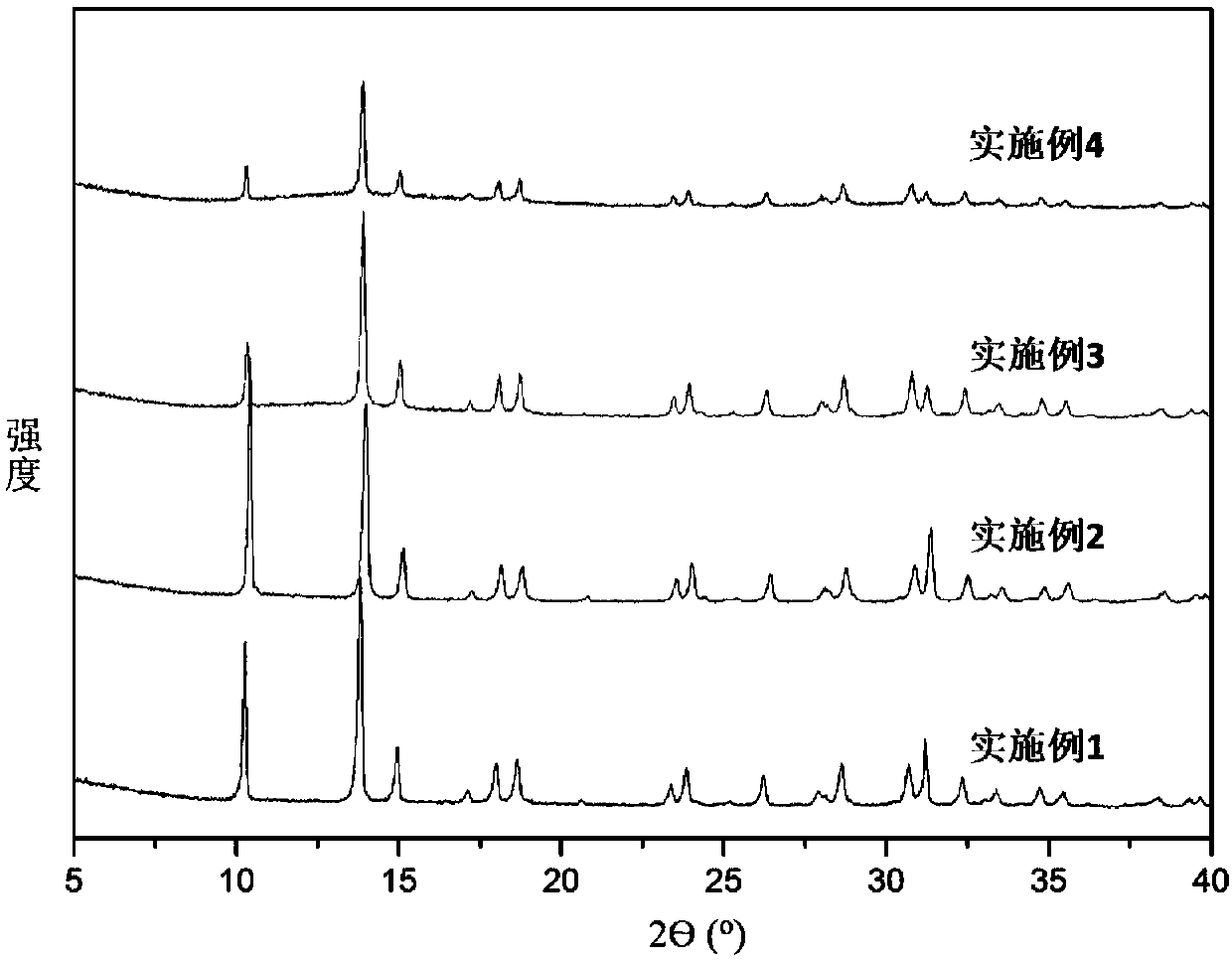

Embodiment 1

[0031] Weigh 0.05mmol of basic zinc carbonate, 0.015mmol of oxalic acid, 0.5mmol of 3-methyl-1,2,4-triazole, 5ml of water as the solvent, stir well, add to the autoclave, seal and put into the oven In 200°C, after thermal reaction for 24h, the reacted mixture was filtered, washed with water and methanol, and then dried to obtain the product, marked as Zn(ox) 0.5 (mtz)-1.

Embodiment 2

[0033] Weigh 0.1mmol of zinc carbonate, 0.1mmol of oxalic acid, 0.5mmol of 3-methyl-1,2,4-triazole, 3ml of water and 3ml of n-butanol as the solvent, stir well, add to the autoclave, seal it Put it in an oven, heat reaction at 180°C for 72h, filter the reacted mixture, wash with water and methanol, and then dry to obtain the product, marked as Zn(ox) 0.5 (mtz)-2.

Embodiment 3

[0035] Weigh 0.2mmol of basic zinc carbonate, 0.2mmol of oxalic acid, 0.1mmol of 3-methyl-1,2,4-triazole, 5ml of water and 3ml of methanol as the solvent, stir well, add to the autoclave, seal Then put it in an oven, heat reaction at 130°C for 48h, filter the reacted mixture, wash with water and methanol, and then dry to obtain the product, marked as Zn(ox) 0.5 (mtz)-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com